Jay Fisher - Fine Custom Knives

New to the website? Start Here

"Raptor"

Beyond simple tools: fine instruments and professional works of art.

Whether at use in the professional kitchen or in processing barbeque, this trio of knives are an extremely well-made, useful and beautiful group of instruments that will last for generations. In this set, I included a very strong, straight slicing and utility knife in my Bordeaux pattern, a heavy and effective classic butcher knife design named Courbe Vaste, and a thin, long, and flexible Thresher slicing and fillet knife.

This versatile trio of knives qualifies for what is sometimes casually identified as a Barbeque Set, but it is so much more. These are professional grade knives, and the designs are crossovers that can be applied to a large range of cutting activities in the kitchen by the chef. There is no reason knives of this caliber should be regulated to a narrow range of tasks, and I'm committed to making wide-ranging functional crossover designs, the first choice and best knives for the job.

I've used premium materials, an ultimate heat treatment, finish, and fitting, to create this useful and dependable set. This is one of the very finest chef's set of knives you will ever see, truly one of the very best ever made, representing my commitment to the science and art of knifemaking and chef's knives.

440C high chromium hypereutectoid martensitic stainless steel is an absolutely excellent steel for the professional chef. The reason this steel excels is because it's a martensitic stainless steel, forming an incredibly strong microstructure of martensite, the acicular, hard crystalline allotrope of the best tool steels. It also can be treated to form profuse carbides: iron carbide, chromium carbide, molybdenum carbide and multi-element carbides. These intricate crystalline structures offer incredible wear resistance and high strength along with excellent toughness.

When properly heat treated, 440C is the most corrosion-resistant of all of the high alloy martensitic stainless steels, with little to no chance of corrosion, even in the acidic and corrosive environments of the kitchen. It does not form these microcrystalline components easily; it takes extremely complicated heat treatment to bring this out. While it can be conventionally heat treated, the difference between conventional processing and a highly sophisticated processing of this steel results in night and day difference in performance and durability. Proper heat treating is paramount, resulting in superior edge retention, toughness, strength, and corrosion resistance.

In order to bring this steel to its zenith of condition, I perform a proprietary heat treating process I call "T3." The technical aspects of this "tertiary third" formation of carbide structure is not a simple process. It takes over a week long, consists of 33 individual specific steps accomplished with high accuracy furnaces working at 1900°F, cryogenic equipment working at -320°F, and numerous staged and ramped process parameters. One small mistake will yield a less than optimum blade, and I'm determined to create the very finest knives made in the world today. Consequently, no other knifemaker, no factory, no machine shop, no heat treating facility will recreate the incredible condition of this blade steel.

The Bordeaux in this set is tempered to HRC 59, for a hard, durable and stiff blade. This is a professional blade that has an incredibly thin cutting edge, with thick, strong spine to support it, and a deep hollow grind that gives this blade an incomparable slicing and cutting potential.

The Bordeaux has a very unyielding character. This is not a flexible blade; the heavy spine is 0.149" (3.8 mm) thick. This—combined with the lengthy heat treatment regime—means that there is no movement in this stiff, large blade, apart from the minimal flexibility at the very tip of the point. The hollow grind of the blade is what I define as a severe grind, similar to what is seen in a straight razor. The hollow geometry is established with a 12" diameter hollow grinding contact wheel. Rather than have substantial thickness at the cutting edge, this knife has a 0.014" (0..36 mm) thickness just behind the cutting edge. This is incredibly thin, the thickness of four sheets of paper.

One of the most notable features of the Bordeaux is the long, extended front bolster. It's made of 304 stainless steel; this is the absolute best material for knife fittings, particularly for chef's knives. This is because it's a zero-care high chromium, high nickel austenitic stainless steel, the same steel used to make stainless nuts, bolts, and fasteners. It's also used to make heavy duty sanitary restaurant equipment, and it's absolutely Food Contact Safe.

Beyond the material, the geometry of the bolsters is unique; I know of no other fine chef's knife that has the extended front bolster. While not used on every knife, on the Bordeaux, this allows a certain and comfortable "pinch-grip" on the bolster, when light work is desired, or high control of the blade point only available in the pinch-grip style. The front bolster is secured with three through-tang zero-clearance pins for absolute mechanical security, and is sealed with food-safe sealant to the tang.

Some chefs prefer to apply a light pressure for control by using the thumb or forefinger on the spine of the knife blade. On a thin blade spine, this can become uncomfortable. In the photograph above, you can see how much bearing surface is available for the thumb or finger on the extended front bolster. It's a wide bearing area, smooth and even, and comfortable to use. In the photo, you can also see the dovetailed front and rear bolster pairs, which positively lock the handle scales to the tang. The scales are bedded, secured, sealed, and solid.

In the photo above, you can see that this knife and the others in this set have a fully tapered tang, which is always seen only on the very best full tang knives. It's difficult to make an accurate tapered tang, which helps reduce weight in the handle without sacrificing strength, balancing the knife overall, and always indicating handmade excellence. I chose to forego any filework that would trap foodstuffs and debris, making the knife comfortable to hold and tremendously easy to clean.

The photo above shows the obverse side handle detail. The knife has a small heel for a tight, compact form, typical for slicing knives. The heel has a rounded and gentle cutting edge transition, to make sharpening easy and smooth. The inside of the bolster curve is polished and tapered for cleanability, and all of the surfaces are contoured, rounded, polished, and comfortable. The belly in the handle, the heel, and the rear "hawk's bill" at the rear bolster help lock this knife into the hand. The "drop" curve at the butt and rear bolster assure comfort in the palm of the hand.

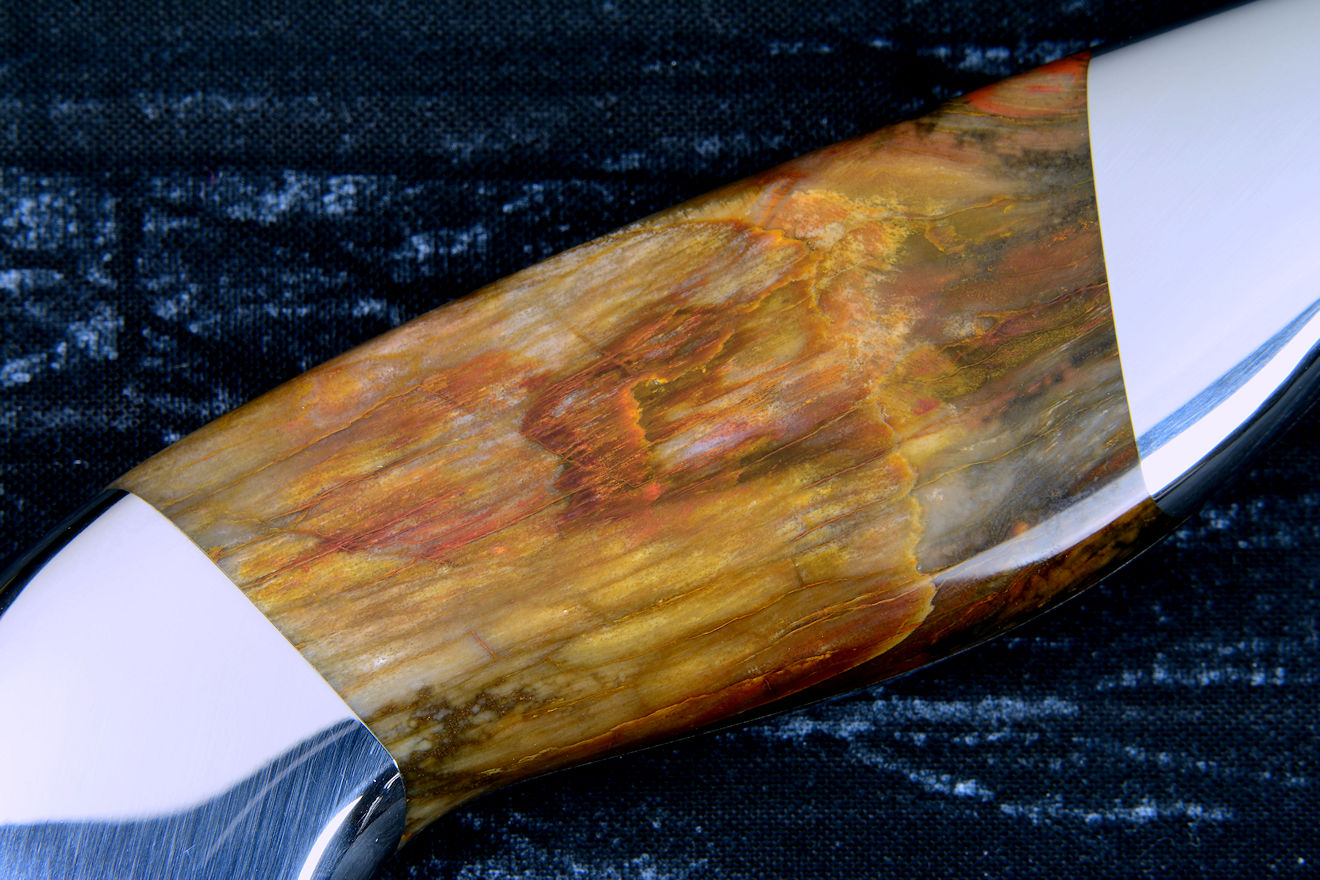

Hard, polished gemstone is the absolute finest premium natural handle material, and this choice was a magnificent one. This is a hard, extremely tough, and beautiful stone; it's a Petrified Wood Jasper from the Caprock region of New Mexico, just north of my studio.

I live on the Llano Estacado, the giant "staked plains" of Eastern New Mexico. The Llano Estacado is over 37,000 square miles, elevated about a mile above sea level. At the northern edge of the Llano, the land drops suddenly, by 1000 feet, and this is the escarpment known as the "Caprock." The Caprock is so prominent that it actually alters the regional weather. The top of the escarpment is of late Miocene to early Pliocene era, putting this fossil at an age of 5-10 million years old. This is the origin of this petrified wood.

The gem has rich, rusty red areas with blending "grain" colored to gold highlights. Darker streaks run through the grain, with swirls and white translucent tiny orbs penetrating the gem. Some of them seem to radiate from beneath. Thin orange seams seem to glow between the solid colors. This is a difficult gemstone to work, bringing out the luster is a challenge, but worth it. This is a stone that changes dramatically depending on the light that it is viewed in, and sunlight makes the colors scream. This is the reason I love gemstone.

It's a very solid gemstone, even and smooth, a wonderful stone that will literally outlast the knife. It's positively bedded and sealed to the tang, securely locked between and under the stainless steel bolsters on all three knives. It's a zero-care stone, an eternal material that took millions of years to create.

Incidentally, Bison—sometimes called "American Buffalo"—freely roam on many areas of the Caprock to this day, as their distant ancestors did in the Miocene.

The next knife in the set is an outstanding classic "butcher's" style of knife. This knife design originated as a modification of my "Courbe" design, which is a thinner, flexible boning and trimming knife blade. I enlarged, widened and strengthened the blade design while incorporating one of my best handle designs. Since it's a larger pattern, I named it Courbe Vaste, which means "broad curve" in French.

The broad curve of the blade is the most predominant feature; it's a spacious, strong blade, hollow ground with a 12" diameter hollow grind contact wheel for wide grind. The spine is wide as well, and along with the hardness I set for the knife at 59.5 HRC, this blade is rigid and stiff. This stiff character supports an incredibly thin and sharp cutting edge, that tapers from 0.024" (0.6 mm) thickness at the choil to 0.012" (0.3 mm) thickness at the point. The point is incredibly fine, behind the cutting edge is just over the thickness of three sheets of paper! The point is supported by good width at that area, as the profile shows in the photo above, with an angle of about 55° between the cutting edge and the spine. The sweeping curvature of the cutting edge is the classic butcher's dream, a knife suitable for skinning and dressing as well; I just love this knife.

The handle has a lot of curves, like the knife, and the hawk's bill at the rear bolsters, the rounded butt, and the smoothed and polished front bolster forefinger area makes this handle a part of the hand. The choil gives a defined and crisp area to start the cutting edge, and the zero-care bolsters mean a knife that is always clean and Food Contact Safe.

Take a close look of the magnified view of this magnificent petrified wood above. The color range, the banding and depth, the character of this rock represents the tree that once was, now millions of years gone. This is a stone that spans the mineralogy between jasper and agate, an eternal reminder of the distant past. What was life like then? These scant reminders are all we have, and the reason we cherish them.

In the photo above, you can see the curves, polished, and rounded surfaces of the stainless steel and the gemstone, and the meticulous fit. As with the rest of this set, the tang is fully tapered and the bolsters dovetailed to bed and lock the petrified wood gemstone to the tang.

The photo above is a 4.4 power enlargement of the gemstone handle material (when viewed on a standard monitor). Some curious things are taking place in the stone. The small white circles are not inclusions of material, and the are not surface color variations. Instead, they are floating within the stone, and the less visible ones are deeper in the stone. They are literally glowing from within. This is why I believe that this is not a solid jasper, but has the properties of jasper (which is opaque) and agate (which is translucent or transparent). These lighter colored areas have their own internal distinct banding visible under a microscope. How did they form and why?

The Thresher slicing knife is a crossover and in quite different character than the Bordeaux and the Courbe Vaste, making this a tremendous trio. I named it for the Thresher shark because of the long, narrow upper lobe on its tail. This knife is large, thin, and flexible enough for dressing marine and ocean fish, and particularly large ones. It's also at home slicing a roast or large melon, since the blade is long, slender, thin, and razor-keen.

This Thresher has the added feature of being thinly ground with a 10" diameter hollow grinding contact wheel, for a geometry that creates a narrow blade width (spine to edge), with a very thin cutting edge and a somewhat stiffer and thicker spine. Because it's so thin, I applied my T3 deep cryogenic process and tempered it to 55 HRC hardness, making it extremely flexible and tough. The point is very thin and aggressive, piercing through with accuracy and ease.

The Thresher has a moderately thin spine for a long knife blade, at 0.085" (2.2 mm). This means it will slip into and through meat and vegetables without substantial thickness to impede the cut, yet with stiffness that the temper belies. The thickness just behind the cutting edge is about 0.021" (.5 mm). This is enough to support the incredibly sharp and keen cutting edge, and it's these small adjustments in the geometry of knife blades that give them distinct and reliable functions. The blade has about a 60° point (curved, so not precisely so), and piercing is well-supported.

The Thresher has a comfortable, safe handle, with a forefinger curve that stops the hand from sliding onto the razor-keen edge, good belly for comfort, and a wide rear hawk's bill bolster that helps counterbalance the long blade. As with the Bordeaux and the Courbe Vaste, the Thresher handle is beautiful, strong, tough, smoothly polished, and bedded and locked to the tang. These knives will last for generations, and knowing that these beautiful gemstones will absolutely outlast the knife is the reason I love this eternal natural handle material.

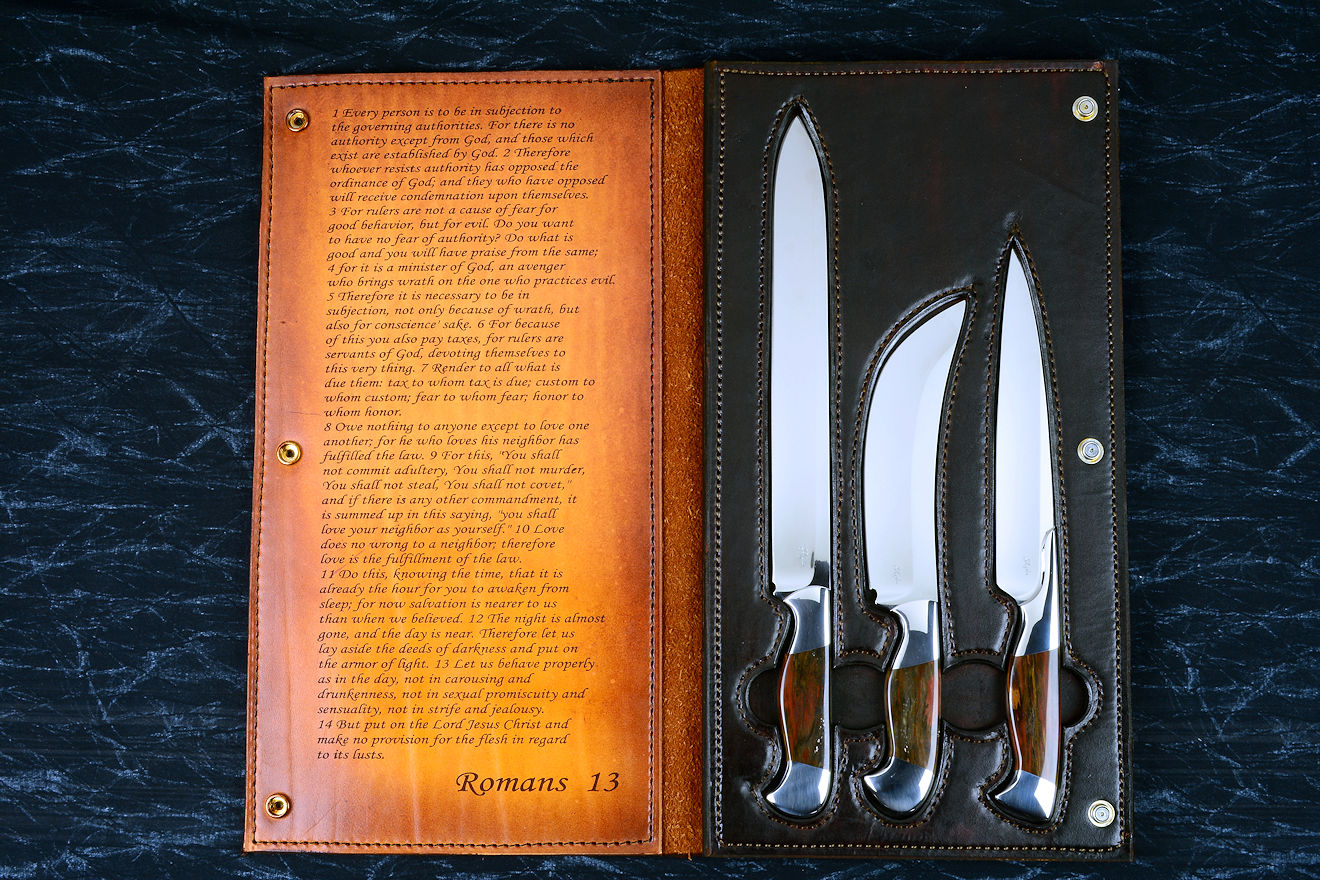

The case for the Bordeaux, Courbe Vast, and Thresher had to be complementary, useful, tough, and beautiful. To house these three relatively large knives requires a sizeable case, and a good deal of leather and stitching.

You simply won't see anything else like it made; this is my commitment to the entire tradecraft and art of knifemaking. I made this case in multiple layers of heavy 9-10 oz. leather shoulder, bonded and stitched with strong, heavy nylon thread that allows a little flexibility and high strength. This is one of my "book" cases, and the knives rest in thick leather pockets, actually surrounded by leather, a true presentation grade case. The outer case is covered with Bison (sometimes called American Buffalo) skin, specially treated and wax-sealed. The Bison is tough and durable, beautiful and bold.

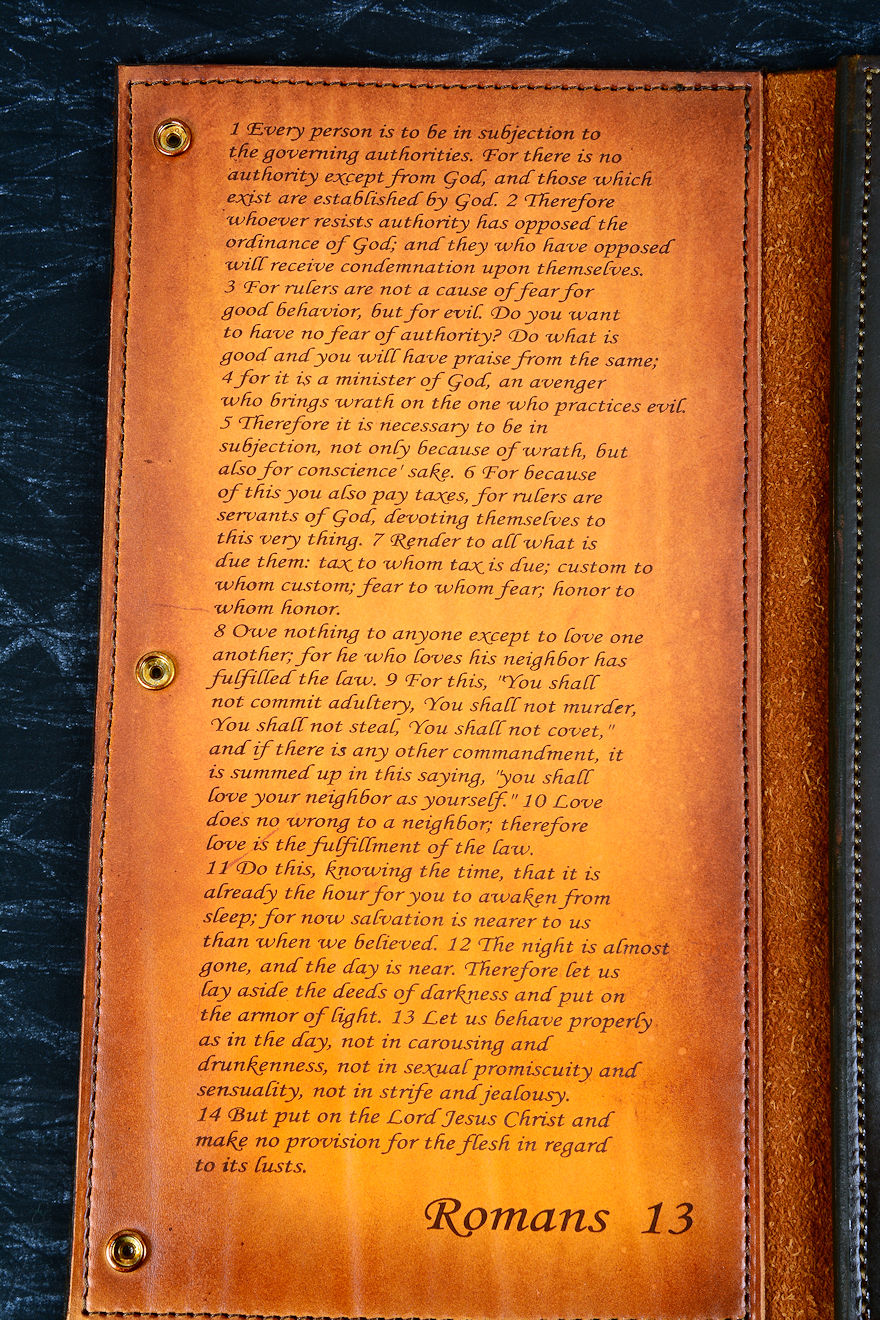

My client requested a special embellishment, and I'm proud to offer laser engraving. The extremely high detail, the deep and even cutting, the beauty of the font is eclipsed by the powerful message of Romans 13. Rather than just a singular verse, the entire chapter is proudly displayed on the inside of the case, cut into 9-10 oz. leather shoulder. The natural appearance of the leather shines through, I've dyed the background in a saddle tan and faded the periphery with mahogany dye. The dedication is sealed with lacquer for longevity.

The leather shoulder used in the body of the case is layered to 0.770" (20 mm) , or over 3/4" thick where the knives rest. These layers are hand-cut and edge-finished, then bonded and stitched with very heavy nylon thread to create an extremely tough and durable protective shell around the knives. When closed, the case is over an inch thick. I've mounted three zero-care stainless steel snaps to secure the case closed.

The case inside is dyed brown, sealed with lacquer for longevity, and heavily bonded and stitched to the Bison cover with heavy brown nylon thread. I've placed perfect finger grooves in just the right locations to facilitate removal of the knives. This tasteful and elegant book case will last for generations with little care. It's a secure case that is an ultimate classic presentation medium.

Please look over the many photos thumbnailed below the specifications for this pair of professional grade knives. I hope you enjoy looking at them as much as I enjoyed making this magnificent pair of knives!

Thanks, S. H.!

| Main | Purchase | Tactical | Specific Types | Technical | More |

| Home Page | Where's My Knife, Jay? | Current Tactical Knives for Sale | The Awe of the Blade | Knife Patterns | My Photography |

| Website Overview | Current Knives for Sale | Tactical, Combat Knife Portal | Museum Pieces | Knife Pattern Alphabetic List | Photographic Services |

| My Mission | Current Tactical Knives for Sale | All Tactical, Combat Knives | Investment, Collector's Knives | Copyright and Knives | Photographic Images |

| The Finest Knives and You | Current Chef's Knives for Sale | Counterterrorism Knives | Daggers | Knife Anatomy | |

| Featured Knives: Page One | Pre-Order Knives in Progress | Professional, Military Commemoratives | Swords | Custom Knives | |

| Featured Knives: Page Two | USAF Pararescue Knives | Folding Knives | Modern Knifemaking Technology | My Writing | |

| Featured Knives: Page Three | My Knife Prices | USAF Pararescue "PJ- Light" | Chef's Knives | Factory vs. Handmade Knives | First Novel |

| Featured Knives: Older/Early | How To Order | 27th Air Force Special Operations | Food Safety, Kitchen, Chef's Knives | Six Distinctions of Fine Knives | Second Novel |

| Email Jay Fisher | Purchase Finished Knives | Khukris: Combat, Survival, Art | Hunting Knives | Knife Styles | Knife Book |

| Contact, Locate Jay Fisher | Order Custom Knives | Serrations | Working Knives | Jay's Internet Stats | |

| FAQs | Knife Sales Policy | Grip Styles, Hand Sizing | Khukris | The 3000th Term | Videos |

| Current, Recent Works, Events | Bank Transfers | Concealed Carry and Knives | Skeletonized Knives | Best Knife Information and Learning About Knives | |

| Client's News and Info | Custom Knife Design Fee | Military Knife Care | Serrations | Cities of the Knife | Links |

| Who Is Jay Fisher? | Delivery Times | The Best Combat Locking Sheath | Knife Sheaths | Knife Maker's Marks | |

| Testimonials, Letters and Emails | My Shipping Method | Knife Stands and Cases | How to Care for Custom Knives | Site Table of Contents | |

| Top 22 Reasons to Buy | Business of Knifemaking | Tactical Knife Sheath Accessories | Handles, Bolsters, Guards | Knife Making Instruction | |

| My Knifemaking History | Professional Knife Consultant | Loops, Plates, Straps | Knife Handles: Gemstone | Larger Monitors and Knife Photos | |

| What I Do And Don't Do | Belt Loop Extenders-UBLX, EXBLX | Gemstone Alphabetic List | New Materials | ||

| CD ROM Archive | Independent Lamp Accessory-LIMA | Knife Handles: Woods | Knife Shop/Studio, Page 1 | ||

| Publications, Publicity | Universal Main Lamp Holder-HULA | Knife Handles: Horn, Bone, Ivory | Knife Shop/Studio, Page 2 | ||

| My Curriculum Vitae | Sternum Harness | Knife Handles: Manmade Materials | |||

| Funny Letters and Emails, Pg. 1 | Blades and Steels | Sharpeners, Lanyards | Knife Embellishment | ||

| Funny Letters and Emails, Pg. 2 | Blades | Bags, Cases, Duffles, Gear | |||

| Funny Letters and Emails, Pg. 3 | Knife Blade Testing | Modular Sheath Systems | |||

| Funny Letters and Emails, Pg. 4 | 440C: A Love/Hate Affair | PSD Principle Security Detail Sheaths | |||

| Funny Letters and Emails, Pg. 5 | ATS-34: Chrome/Moly Tough | ||||

| Funny Letters and Emails, Pg. 6 | D2: Wear Resistance King | ||||

| Funny Letters and Emails, Pg. 7 | O1: Oil Hardened Blued Beauty | ||||

| The Curious Case of the "Sandia" |

Elasticity, Stiffness, Stress, and Strain in Knife Blades |

||||

| The Sword, the Veil, the Legend |

Heat Treating and Cryogenic Processing of Knife Blade Steels |