Knife Anatomy, Parts, Names, Components, Definitions, and Terms

Right now, you are reading the best singular knifemaker's website

ever made on our planet. On this website, you will see many hundreds of

defined knife terms, detailed descriptions and information on heat

treating and cryogenic processing, on handles and blades, on stands and

sheaths, and on knife types from hunting and utility to military,

counterterrorism, and collection. You can learn about food contact

safety and chef's knives, you can find out what bolster or fitting

material is best for each application and why. You can lean about caring

for a knife, you can see the very largest knife patterns page in

history, with many hundreds of actual knife patterns and photos of

completed works. You'll also be able to see thousands and thousands of

photos of knives, knifemaking, processes, and creations, with many

hundreds of pages of appropriate, meaningful text. You might want to

know why a knife blade is springy, you might want to know why a hollow

grind can last longer than a flat grind. You might want to learn about

some pitfalls of the tradecraft, and you might even want to have a

chuckle about funny and strange email requests.

You'll find all that here, on JayFisher.com, and you won't find it

anywhere else!

Learn

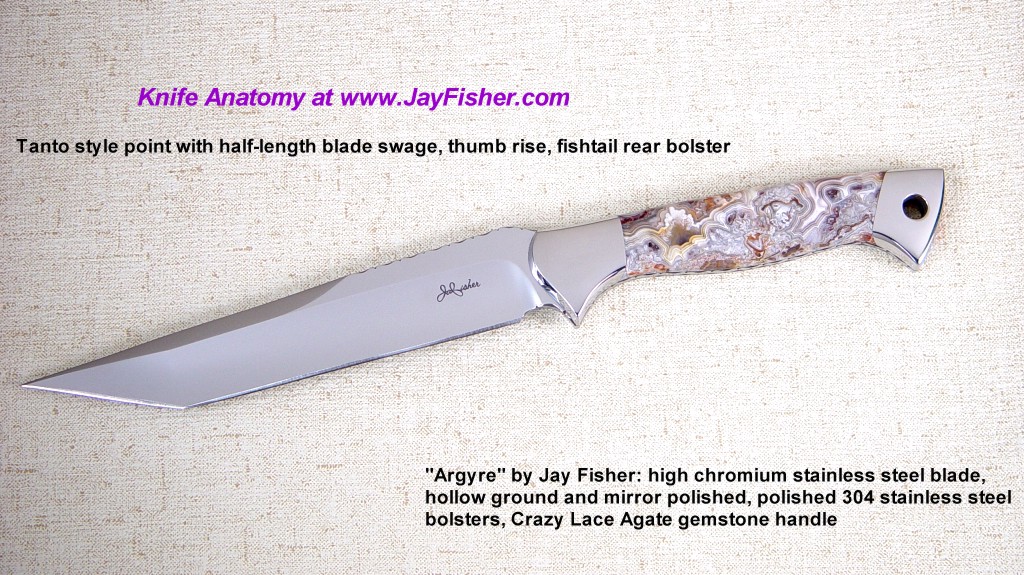

more about Argyre

I am committed to making completely and clearly the best knives in the world.

--Jay Fisher

More

Warning: Copyright details at the bottom of every page

Don't worry about using the wrong word or phrase if you contact me about a knife project. I'm expected to know these terms, not you; I fly the plane,

you just tell me your origin and destination.

Learn

more about Pherkad

Welcome! If you are coming from the many links to this page on the internet, or if you are

arriving from this very site, you have reached one of the most popular pages on my web site. This is

because there is a great interest in knife parts, designs, components, anatomy, and terms, and a lot of confusion,

misinformation and mistakes in knife terminology exist on the web.

In keeping with my commitment to service in my tradecraft and art, it is my goal to create the

best single knife maker site on the internet, and it's all thanks to

you: the public viewer, knife enthusiast, and aficionado.

You don't make several thousand knives in a career without

a lot of experience, thought, and details. So I've created a series of pictures and drawings

to illustrate knife components, parts, and anatomy. This will help with

conversations and knowledge about knives in general, and educate about

common current and historic knife components, leading to easier conversations about custom knives, their construction,

shapes, features, and details. I've sprinkled in a few large pictures of some

knives I've made with general details and descriptions so you

can get a good idea of the modern handmade and custom knife and its

description. Please enjoy my work!

Page Topics

First let me start off by saying that this site is great. I love the "Knife

Anatomy, Knife Parts, Knife Names, Knife Components". Who knew

there were so many parts to a knife?

--D.B.

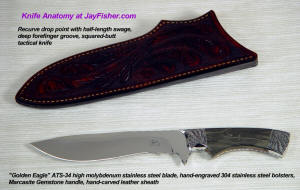

Learn

more about the Golden Eagle

Modern knife makers speak their own language, and if you

hang around them long enough, you'll pick up the terminology and soon be able

to distinguish an uneven grind radius from a non-parallel spine flat. It seems

every knifemaker has his own terms for his knives, and if you make enough knives,

you'll have to name those components somehow, just so you know what to

call them! Most of these terms are pretty well established, but may not

correlate with historical norms. For instance, the quillon (or quillion) of a

guard are the horizontal bars that extend perpendicular to the axis of a sword or

dagger, but nowadays the quillon also refers to the protuberances that stop your

fingers from sliding forward onto the knife blade and cutting edge. The French word quillon is

pronounced "key-own", but if you pronounce it "quill-yun", I'll understand. I'll detail these

points as I go along, and I'll also continually add to this page with

sword and dagger definitions and details, terms and descriptions common to

tactical or combat knives, and maybe even sheath, stand, and case parts, if

you're interested! I go into much greater description and detail in my

upcoming book.

Page Topics

Aloha, Jay:

I just want to thank you for writing an excellent treatise on knives. I mostly deal with Nihonto (Japanese swords) these days,

but still have a great Damascus knife collection. I'll be looking into buying one from you sometime soon.

Mahalo! (Thanks!)

Ken

Ken Goldstein, Ph.D., P.E.

President, Japanese Sword Society of Hawaii

Kaneohe, Hawaii

Learn

more about Vespula

Sophistic linguistic vain superiority, doctrinarian, snobby verbal

claptrap. A knife is just a piece of metal and a handle. Why bother? Who

cares?

Evidently, someone cares, as this page is

consistently one of my top three hitters on the website,

averaging thousands of hits every day, month after month, year after year. One may ask the

jeweler why there are so many terms for his tradecraft,

definitions for components and objects and specified nomenclature

for areas and locations of a simple ring, bracelet, or necklace. Add to the

comparison that jewelry does not typically do anything but be

worn and present,

whereas the knife is a tool and must perform cutting tasks, and it can be bewildering the

number of terms and descriptions available in either the jeweler's or knife

maker's world.

I do not claim any elitist title, degree, or

qualifications for naming and describing these terms, only

my forty years of experience making knives, and over thirty years as a

full-time professional custom

knifemaker. In the profession that I have, a substantial amount of research,

study, and historic perspective is necessary. These are the terms that I believe that

are most often used, defined, and carried in this field, in

contemporary times of the modern English language spoken in

the United States of America. Even in our own country, there are dialectic

variations of terminology that can confuse definitions, so this is by no

means an exact science.

As expected, you can't make a serious business for decades and have a substantial internet presence without

running into critics. The internet is rife with critics, people who have no training, no experience, and no

measurable level of expertise apart from the ability to post (anonymously) their opinion. Since successful

people are targets, even the most definitive, current, descriptive, and referenced knife anatomy and definitions

web page in the world is criticized. The ignorant will often go onto any forum that will conceal their identity and

make claims like "that website is just wrong." This is not accompanied with any logical, reasonable, or descriptive

terms, words, or definitions, yet the ignorant will to on to claim that a ricasso is a choil and other such

ridiculous nonsense.

By the way, welcome to the most definitive, current, descriptive, and referenced knife anatomy and definitions

web page in the world. I'll do my best to keep this critical reference page up do date. Thanks for being

here and sharing the voyage into monoglotistic indulgence!

Page Topics

Enthusiasts soon understand each other.

Edward Irving

18th century Scottish preacher

Congratulations Jay.

It is rather refreshing to come across inspired and inspiring people like you.

Many thanks for sharing your thoughts, knowledge, and expertise.

--J. G.

Portugal

A simple knife seems easy to describe. A blade and handle are the obvious terms that

generalize the knife as a hand knife. A hand knife is one that is meant to be in the hand.

You might be surprised how many knives are in the world; there are knives to plane wood,

knives to shear steel, knives to separate particles in industrial process applications. In my

upcoming book, I'll go into the bewildering classification of knives and blades, and our

government's idea that they can classify, track, and identify them all!

Learn

more about Izumi

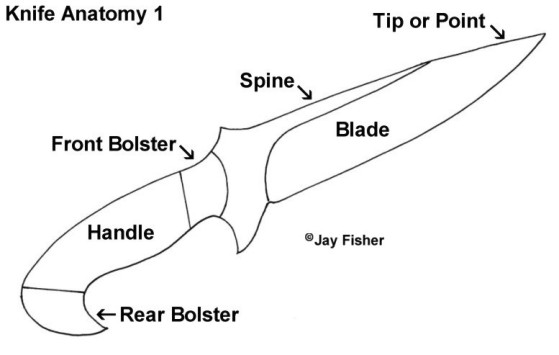

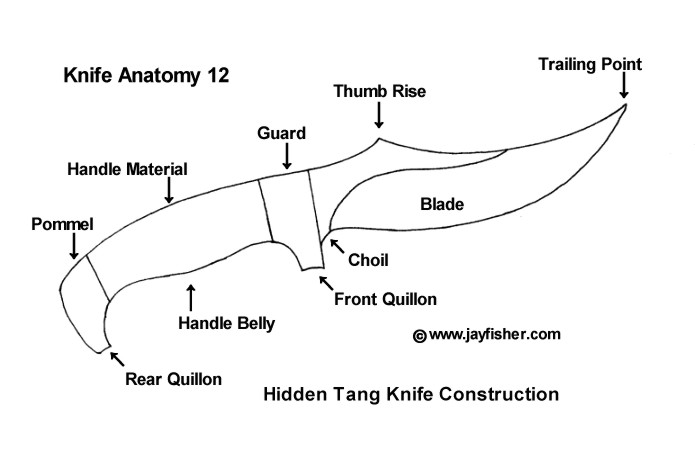

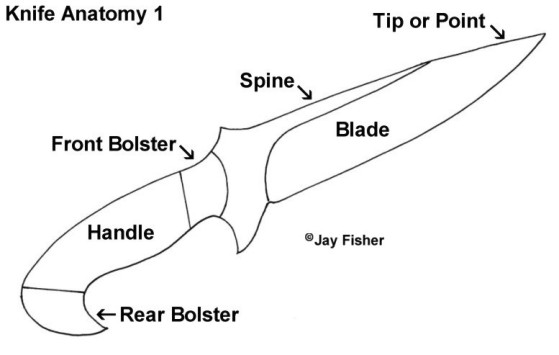

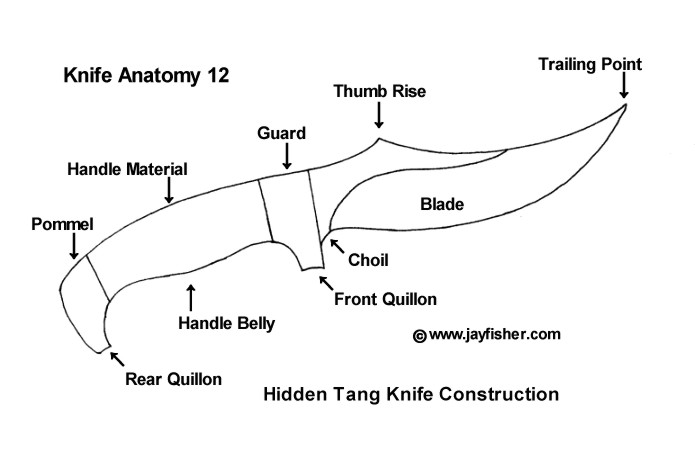

The following dozen illustrations point out and describe various

hand knife components and areas. It's easy enough to identify

specific components and their location (like the point of the

blade), other knife parts are more generalized to an area (like the

grind). Items that accompany, are part of, or are attached to the knife blade (like the bolsters)

can have widely varying shapes, arrangements, and purposes.

I use all my own knives and patterns for the illustrations on this page. Over

500

different patterns can be seen on my Patterns page, and the

Featured Knife pages describe

hundreds of individual knives. I'll continue to expand this page, the

definitions, descriptions, illustrations, photographs, and terminology

as time permits, adding new styles and arrangements.

Page Topics

This picture

starts what seems to be obvious. The knife has a handle and a

blade. The blade has a point (or tip) and the point often determines the use,

style, and connotation describing the knife blade shape. More on that later.

The spine (also sometimes called the back) is the thickest, heaviest

length of the blade and supports the entire blade. The wider and thicker

the spine, the stronger the blade along its length.

You might read elsewhere on the internet that it is debatable whether the

full tang or the hidden tang is stronger. This is not even a close

argument. The full tang

has full thickness across the width of the blade at the most critical area, in front of and

behind the front bolster location. On a hidden tang, this is where the blade is ground down

and reduced in size and thickness to a shoulder (below). The hidden tang also only has a small width of tang running through the handle to the threaded

portion where the pommel is screwed on. So there simply is no way that the hidden tang is even

comparable in blade-to-handle strength to the full tang. The hidden tang simply has less metal

in the entire handle. Detailed description and illustration of the

hidden tang knife handle below.

The handle of this full tang knife is framed in by

the front and rear bolster. The bolsters do exactly that,

they bolster the blade's strength in the critical areas: the handle to

blade junction, and the rear or butt of the

knife where heavy blows or impact require reinforcement. The bolsters

also help to protect and mechanically secure the handle.

The pattern used for illustration here is my Cygnus-Horrocks design.

Page Topics

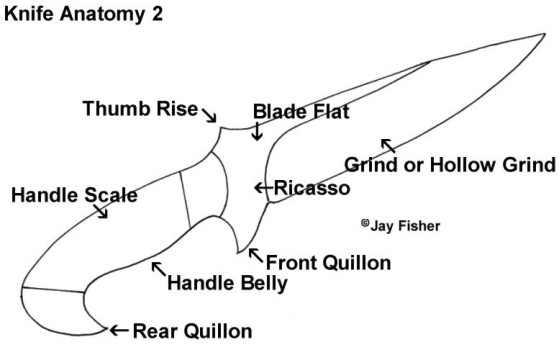

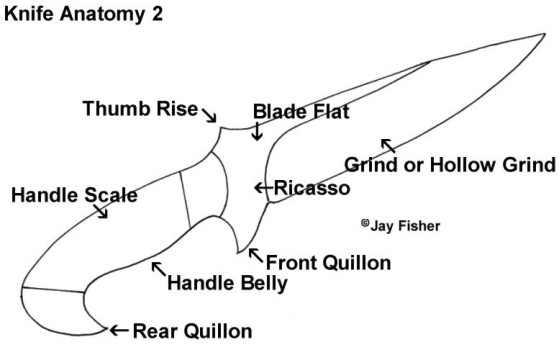

A few more details here.

The thickest part of the knife blade: the spine, is also the blade

flat, the part of the blade that is flat ground and both sides are

typically parallel. It extends up

to the thumb rise

on this example, where the thumb rests in a traditional grip style, and

down to the ricasso, the heavy thick shank of the blade

between the grind and the front bolster. It extends (in this

illustration) toward the point. The grind or

hollow grind in this case is the part of the knife where the

blade is thinned along its length to yield a uniform, thin cutting edge.

The grind is a very distinctive part of the knife, and fine workmanship

is usually noticed here by how deep, matched, regular, and

well-finished the grind is.

Some older texts and beginners in knife chat sites and forums call the grind a bevel

but this is technically incorrect, since there may be many actual geometric

bevels on a knife, and a bevel is a slope or slant of a line, and

therefore straight. On a flat ground knife, one might call it a bevel,

but knives are ground in many ways: hollow, convex, tapered, flat, and

even a combination of grind geometries. Since modern knives are nearly

all abrasively ground, the area is called a

grind.

The front quillon stops the hand from sliding forward on the blade, and in this knife

pattern, the hand is locked between the front and rear quillons. The

rear quillon also aids in removing the knife from the sheath. The

handle belly makes many knives more comfortable to hold. The

handle scales rest between the bolsters and should be

pinned, riveted, screwed, or mounted with mechanical as well as adhesive

means.

The pattern used for illustration here is my

Cygnus-Horrocks design.

Page Topics

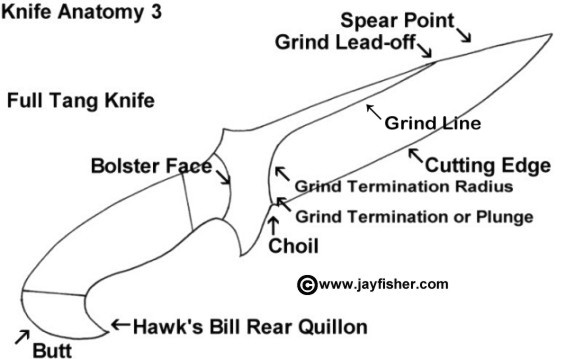

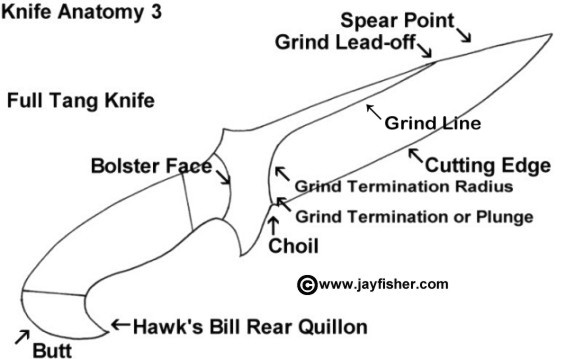

A spear point designation used to refer to a double edge, but nowadays it can refer to

the almost uniform geometry of the point. If you were to bisect the

profile of the point, you would see a nearly symmetrical profile on both

sides of the center line, like a spear of old. In this drawing, you'll

notice grind terminology. The grind termination is at the

ricasso, plunges into the meaty part of the blade, has a

radius that delineates the transition between the grind termination and

and the grind line, and leads off the blade at the spine near the point. The grind termination

radius is determined by the wheel size if hollow ground and

other factors.

The choil is considered the start of the cutting edge. In days

of old, the choil was perpendicular to the edge, and is often still

described as the lower part of the ricasso, the part that is unsharpened

and at the full thickness of the blade. In the modern knife, it can be

carved, fluted, fileworked, and a separate feature of a fine knife. It's

purpose is to have a definite location to start the sharpened edge of

the knife.

It's interesting to note that for nearly all

United States locations, laws state that blade length is not the length

of the cutting edge, but the length of the blade from the tip to the

front bolster face.

In this drawing you can see why this rear quillon is often called a

hawk's bill.

The pattern used for illustration here is my

Cygnus-Horrocks design.

Page Topics

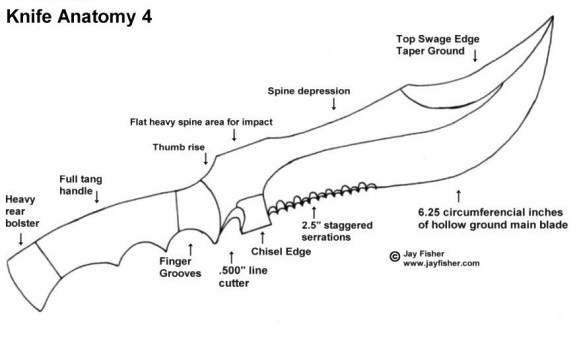

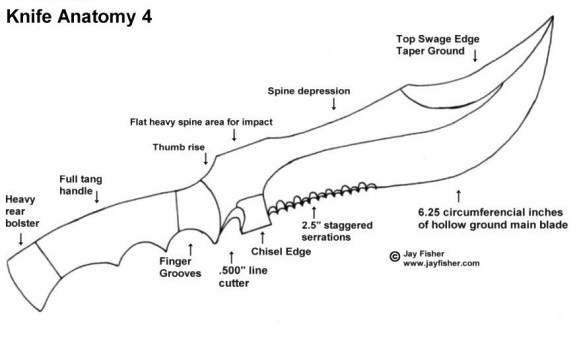

Here is a remarkably

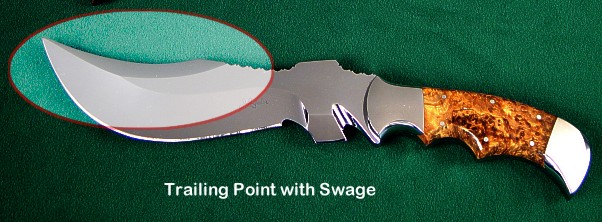

different knife. You'll notice the point is trailing, that

is the point trails higher than the spine. It has a swage,

which is a separate grind that can be sharpened or left unsharpened

(sometimes called a false edge). The purpose of a swage is to

reduce the cross sectional area of the point without sacrificing too

much thickness at the point. Then, being more pointed, thrusting

insertion is improved. Though the swage is technically not a separate cutting

edge, it can be made vey sharp by creating it as a single tapered bevel.

This knife also has a blade with a deep belly

(the curved arc of the main blade). Serrations are usually

placed near the handle, for greater application of leverage. This knife

also has a separate chisel edge for hammering through

wire, and a canted (angled) line cutter.

This knife is designed for both tactical combat and survival.

The handle has finger grooves, deep depressions that accommodate

the fingers. Note that in this particular knife handle, there are two finger

grooves for the index and middle finger, and a wider singular depression

for the smaller fingers of the hand. This can help the handle

accommodate a variety of hand sizes, as the two rear fingers float.

Judging from the size of the handle and blade, this is a large, heavy

knife. one can see that the blade would have substantial mass, placing

the center of balance forward into the blade.

The knife pattern used in this drawing is my "Flammarion." A

similar model is the

"Flamesteed."

Page Topics

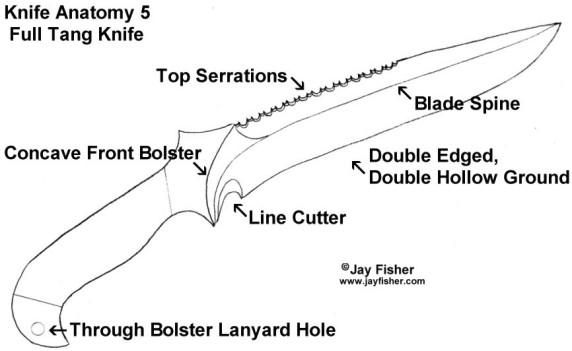

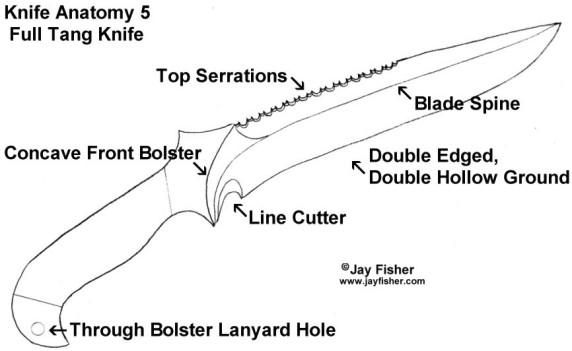

This full tang knife is double edged, and the top edge has a great length of serrations.

Though this is uncommon, the design is such that the knife can be drawn

through rope or textiles by cutting upward. Not a feature for the casual

user, as cutting toward oneself can be dangerous. This is clearly a

knife for the professional.

Note the shape of the front bolster face. It is curved inward, concave,

so that strength and coverage of the bolster to tang junction is

increased. Note also the lanyard (or thong) hole is

milled through the rear bolster and knife tang for great strength. A

short lanyard (length of cord) is often used to assist locating the

knife in the dark, or underwater, and to aid in pulling the knife from

the sheath. It can also be used as a security measure wrapping around

the wrist, or be tied to the belt.

This knife design has a long handle with a belly shape, minimizing the separate

and distinct finger grooves. The heel or butt of the handle is curved downward

to accommodate the heel of the hand. A thumb rise is even with a front bolster.

The double edged knife nowadays is sometimes called a dagger, but this

is historically incorrect. A dagger is strictly classified as a short weapon used to stab.

Since not all double edged knives are used to stab, this is technically incorrect.

Typically, a dagger is nowadays referred to as a symmetrical knife with double

edges.

The knife pattern used in this drawing is my

"Oceana"

Page Topics

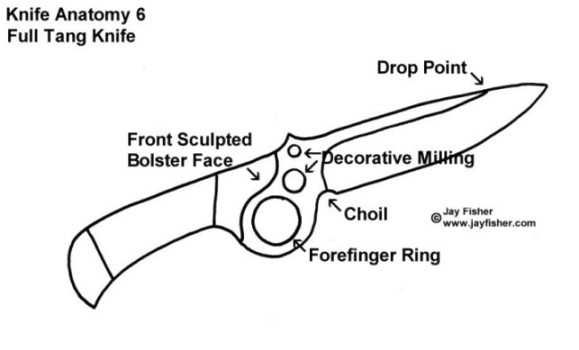

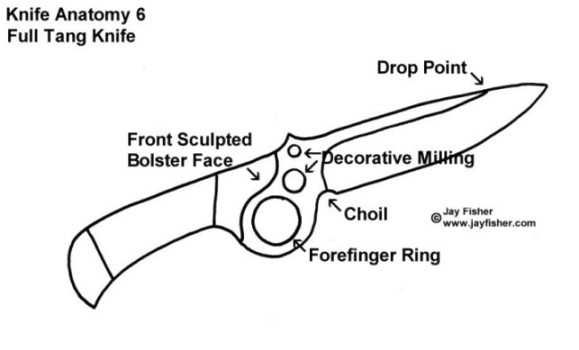

Here's a full tang knife with a

drop (or dropped) point. The point "drops"

lower than the spine. It's a strong point whose curvature allows very

easy insertion in the sheath. Trailing point knives have to be eased or

carefully curved into the sheath to prevent the point from cutting the

sheath welts, but drop points can be self-guiding and the knife just

shoved in, often without looking.

You can see that the choil is very pronounced on this design, and

that a greater measure of security for the forefinger than a quillon is

the full finger ring. Preferences vary and opinions differ

about the finger ring. Disadvantages: it can trap the hand, it takes

longer to thread the finger through, it adds to the width of the stock

and weight of the blade. Advantages: unsurpassed security between the

knife and hand. A finger ring is a frequent request and feature on my

tactical

and combat knives.

Note the sculpted front bolster face, an

advanced feature on a custom knife. Sculpting or shaping the bolster

requires a group of additional steps, and the bolster face should be

tapered away from the blade, not squared-off, as this may trap and hold

debris and make the blade difficult to clean. Additional pins and

mechanical arrangements to secure the bolster to the blade are well

applied here.

The knife pattern used here for illustration is my

"Diacria"

Page Topics

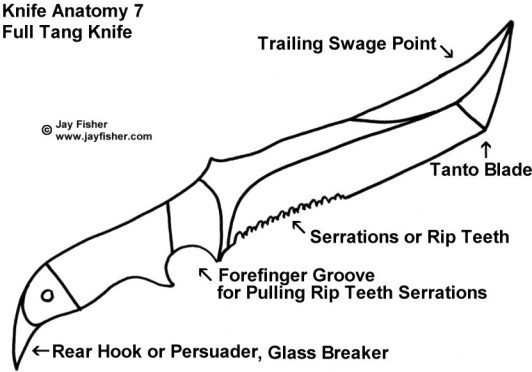

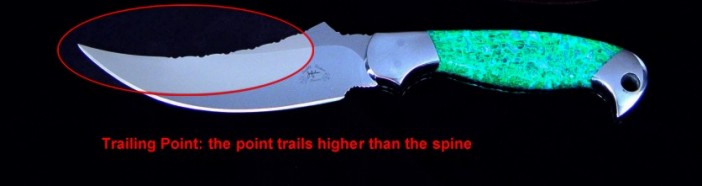

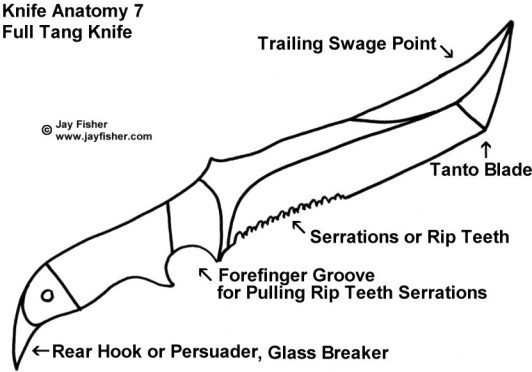

Another trailing point

with a swage. Previously, I described how a trailing point is harder to

sheath and from this drawing, you can see that the aggressive

point would rip right into the welts of a sheath if not carefully

guided into the sheath. The advantage of a trailing point is the very fine, sharp

point, the finest point of any blade style. It's, unfortunately,

weaker than other tip shapes, as the cross-sectional geometry can be very thin.

This knife has a tanto style blade,

very popular in recent years. One of the reasons is that where the

"Tanto Blade" arrow points in this drawing is a secondary point,

and the hand can bear down on that point by applying pressure on the

spine back and apply tremendous pressure in cutting. The line

prescribed by the union of the tip grind and the main blade grind is

called the dividing line or yokote (definitions

below).

Note the forefinger groove that is

backed with a canted, deep back. This is to apply pulling pressure when

the serrations are ripped through material. I often call them "rip

teeth" because that is ultimately what they do.

This knife also has a rear hook, or

persuader. These protrusions of the rear bolster or butt

of the knife are used in tactical knives to "persuade" an enemy or

opponent along after capture, and as it is not sharpened, will not

usually cause an open wound. It can also be used as a glass breaker, a

point to hammer through tempered safety glass in an emergency. Other

names used for this device are skull crusher

(self-explanatory), talon, and cat-scratcher. The reason for that

name is that if the knife is handled frequently during tactical

practice, the knife user's arms will often be marked with scratches from

this protrusion resembling scratches from a cat.

Page Topics

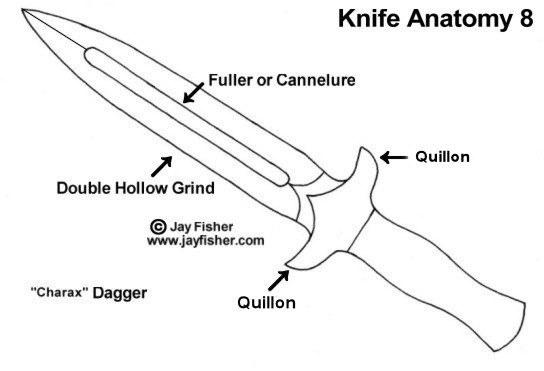

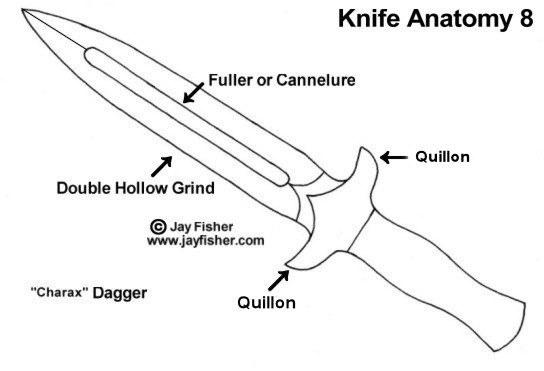

This is what is contemporarily known as a dagger, a

double-edged knife that has symmetrical or double hollow grinds. The

center axis of the blade has a milled fuller or cannelure. The fuller or

cannelure allows a reduced central weight in the thickest area of the

spine without sacrificing strength. In essence, it forms an "I" beam

running down the center of the blade, and limits lateral flexion. You

will see this feature more on longer, larger blades, like sword blades.

It is not a blood groove. The term blood groove is an American

colloquialism and means nothing. We've all heard that the groove is made

to allow blood to flow in a deep cut, but this is simply an uneducated

attempt at describing the fuller. The fuller is named for the special

hammer and anvil tool set (a fuller) used by a blacksmith to produce the

groove that spreads hot iron. In my book I go into greater detail about this

mysterious and misunderstood groove in a blade.

This particular dagger was designed for tactical and combat use. It

is full tang, one solid piece of steel from tip to butt, and has wide

quillons to guard the hand. Since it's full tang, the quillons are

reinforced with a bolster pair over them, creating a very strong knife

indeed.

The handle has some belly for improved grip.

The blade grinds in this case must be of a small wheel

diameter, to preserve thickness at the central spine of the

blade. Otherwise, the blade would be too thin and subsequently, weak.

The knife used here for illustration is my "Charax" pattern, a tactical combat dagger

Page Topics

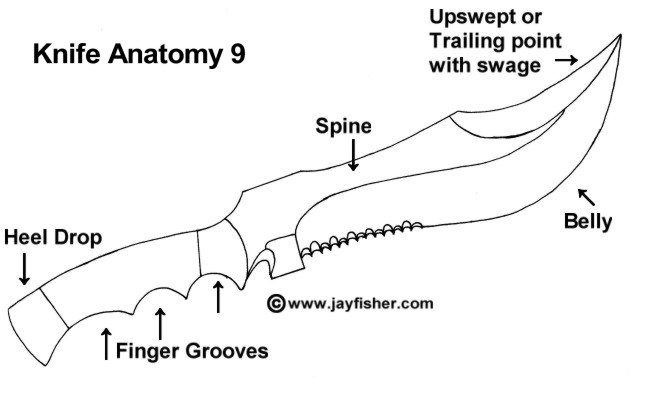

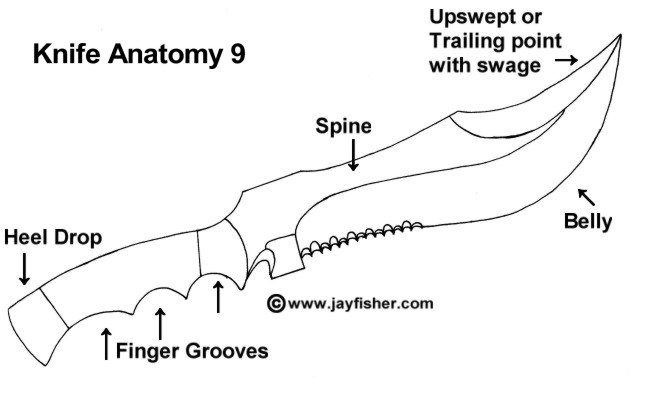

You've seen my

"Flammarion" pattern before. Nice knife! Here I have highlighted some

more components. The spine is the thickest, heaviest,

strongest part of the knife, and in modern hollow ground knives is

usually left at full thickness. This knife has an upswept

or trailing point, that is, the point trails higher than

the spine of the blade. Notice the belly

on the blade. It is the most convex part of the blade geometry, and in a

hollow ground knife, can be devastatingly sharp. Due to the geometry, in

tactical combat knives, creates a great slashing geometry rather than the

cleaving geometry of straight blades. It's very hard to create a good,

deep belly on a blade no matter how it is ground. Enough thickness

should be left in the blade stock for strength, but enough thinness at

the cutting edge for the geometry to be effective.

Notice also the

highlighted heel drop. This is at the rear of the handle,

and allows the heel of the palm more comfort. Humans have heavy, thick

tissues at the base of their palms, and the heel drop on a well-designed

handle can accommodate this human anatomy. Note also the finger

grooves in the handle.

A similar knife I've made is my

"Flamesteed."

Page Topics

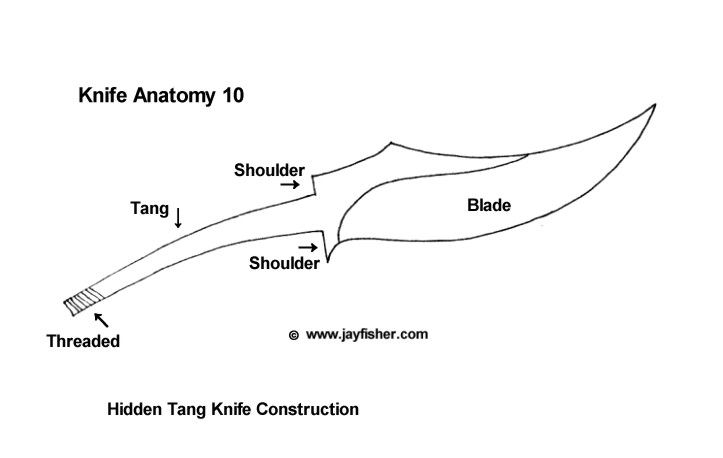

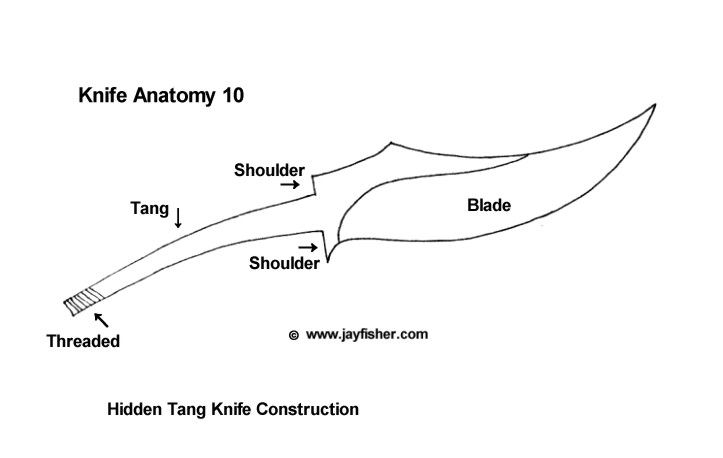

Hidden tang knives are constructed with a full blade and a handle that is supported between

the threaded tang end and the shoulder. The tangs may be straight, which makes construction of

the handle easier, or curved (as shown) which can create a more natural

handle shape. In some colloquialisms, this is called a "rat tail" tang, but that is

just wrong, and the tang may be shaped in dozens of ways. The tang may be a solid piece of the same steel as the

blade, or a treaded tang or rod may be hard-soldered or

welded onto the knife tang.

The reason for a hidden tang is a fuller,

more rounded handle shape, conservation of expensive blade material, or

design. Obviously, it is not as strong a knife as a full tang knife. The

weak areas are at the shoulder and at the threaded

tang end. For more details about strength, practicality, use, and

limitations of the hidden tang vs. full tang knife design, link to my

FAQ page at this section: Full Tang or Hidden Tang?

The knife shown in this pattern is my "Aunkst" trailing point hunting knife.

Page Topics

Right: hidden tang heavy knife construction, with 3/8" threaded

stainless steel rod welded and annealed to CPMS30V tang, all stainless

steel fittings, pommel, and guard on this "Yarden."

Right: hidden tang heavy knife construction, with 3/8" threaded

stainless steel rod welded and annealed to CPMS30V tang, all stainless

steel fittings, pommel, and guard on this "Yarden."

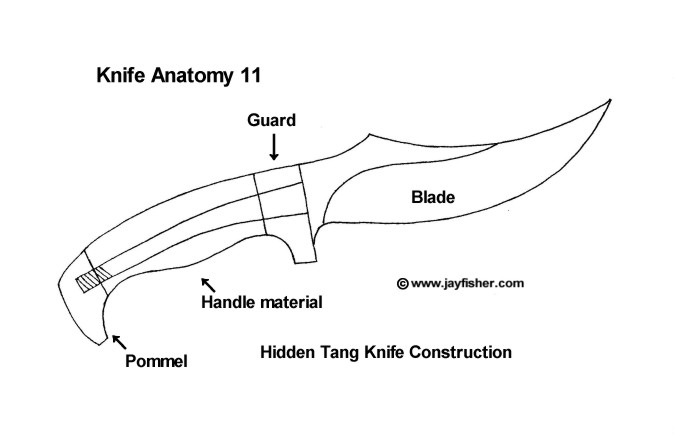

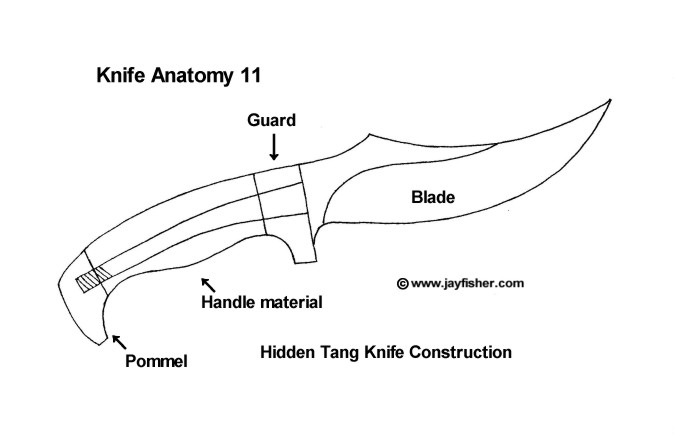

Here's the same knife pattern as shown in Knife Anatomy 10 above, with the guard,

handle material, and pommel shown transparent. The guard is usually milled

through and can be soldered onto the

blade at the tang shoulder, creating a tight, sealed fit between the

guard and the blade. The handle material has a drilled and milled hole

down the center, where the tang sits. The handle may be multiple pieces

of materials, including spacers (see "stacked tang" definition below).

The strength of the handle is complete when the pommel,

which is drilled and tapped, is threaded onto the tang end, tightening

the entire handle. This entire handle, guard, and pommel assembly may be

filled with epoxy or bedding compound to solidify and seal the handle.

The knife shown in this pattern is my

"Aunkst" trailing point hunting knife.

Page Topics

Right: hidden tang knife construction dry fit, with all stainless steel

components for high strength and durability, with Sambar stag horn

handle on this "Yarden"

Right: hidden tang knife construction dry fit, with all stainless steel

components for high strength and durability, with Sambar stag horn

handle on this "Yarden"

Here's the hidden tang knife, completed. You can see how the handle does not show any tang

metal for a natural appearance, and the shape of the handle does not

depend on the shape, angle, size, or position of the tang, so a full

sculpting of the handle shape can occur. Note how the quillons

and handle belly make this an attractive and comfortable

handle.

This is one of my most popular knife patterns, the

"Aunkst."

Page Topics

Right:

Completed hidden tang construction of this "Yarden" (see previous two hidden tang boxes above). Heavy stainless steel construction,

stag horn filled with high strength epoxide compound for solid, permanent attachment.

Right:

Completed hidden tang construction of this "Yarden" (see previous two hidden tang boxes above). Heavy stainless steel construction,

stag horn filled with high strength epoxide compound for solid, permanent attachment.

Just found your website – New item on my bucket list – to one day have you create a knife for me!

Beautiful knives, website and very informative; I just spent the last couple of hours (maybe it was more

like 4 hours) reading some of the most straight forward and insightful knowledge on knives. My head is spinning !

Wow and wow – thanks for all of the hard work on creating your website and one day . . . a knife of yours will be mine!

--Danny Schmider

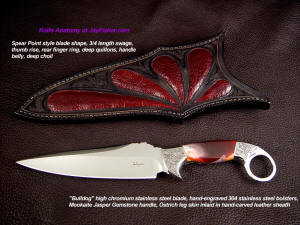

Learn

more about this "Bulldog"

There are thousands of blade shapes, but most fall into

several simple categories. Most modern descriptions for the shape of a

blade start with the description of the point. Points may be at a very acute

angle or they may be wide, even obtuse (over 90 degrees). The design of the

point may support a very thin grind, or a very thick one, increasing point

strength. The point may have a very thin cross-sectional thickness for

better piercing, or may be clipped off for a thicker geometry. Typically,

my combat knives have a swage at the top of the spine to decrease this point

thickness for piercing. Knives used for caping or delicate piercing and

cutting chores are thinner overall, as they are not expected to encounter

aggressive piercing movements.

Below are a group of knife blade shapes, classified by the point and blade

shape. Though there are many other descriptions, names, and classifications,

these are the general styles I use today. Most contemporary knife makers,

users, and collectors will recognize the styles.

Page Topics

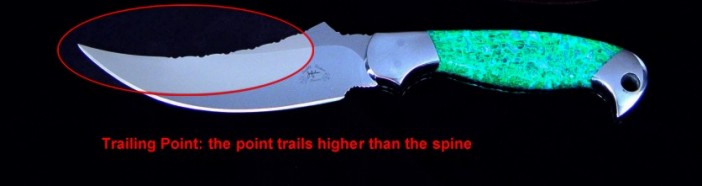

The trailing point is named for the point which trails higher than

the generalized axis of the spine of the knife blade. It is the sharpest point for

fine, delicate, and small work (such as skinning and caping game). The trailing point is the hardest to sheath,

as the point has to be carefully guided and rolled into the sheath so the point does not poke and cut

through the welts, stitches, or side wall of the sheath. The thin and high point is also the

weakest structural area of the blade. The blade tip and sweeping belly are very useful in skinning game, as

the blade is drawn toward the knife user in a sweeping motion, cleanly separating skin and fascia. This blade

design is mostly seen on hunting or game field dressing knives.

This is my "Aunkst" full tang pattern. Note the tall thumb rise for control and rear hawk's

bill quillon with large lanyard hole through tang and bolster. This elegant skinner was designed by

a professional hunting outfitter. The chrysocolla gemstone is stunning in color, pattern, and texture.

Page Topics

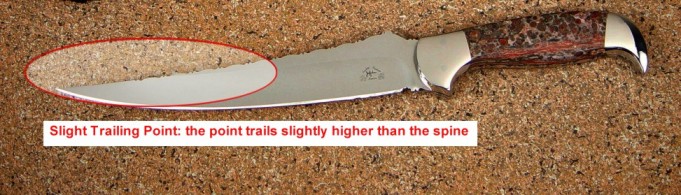

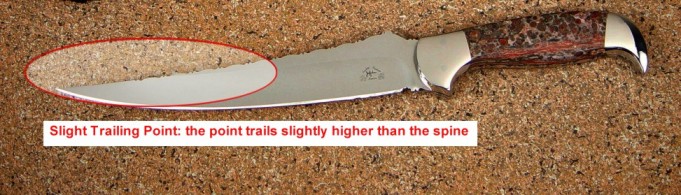

This knife is a tactical model with a very slight trailing point. If sufficient thickness

is left at the point, the slight trailing point can be devastatingly effective in combat use

for piercing. Note the absence of a top spine swage, as the point is thin enough without

the cross sectional-reducing properties of the swage. Even so, careful and skilled blade

hollow grinding practice must be applied in order to leave enough metal at the point to

preserve strength. The temper of the blade is also effective in controlling any possibility

of a brittle blade, and the point and blade should be tempered back a bit if the point is

thin, increasing overall toughness.

The curvature of the blade profile

allows slashing defense, and the thumb rise on this particular pattern gives a great deal of

control and considerable area for bearing down while cutting. This knife is easier to sheath

than the radical curved full trailing point above, but care must still be taken to

avoid piercing or damaging the sheath body or welts.

The knife shown is my "Zorya" pattern, in mirror finished stainless steel blade and fittings

with an orbicular jasper gemstone handle. Note the filework which can reduce slippery blade spines

and the notable quillons that lock the fingers into the handle. The blade has a sculpted choil

for a defining termination of the cutting edge. See a

fine "Zorya" here.

Page Topics

This blade shape is very popular with combat and rescue personnel,

as the angle of the tip is less acute, and therefore has

more cross-sectional area and more metal to support the point. This is one of

the strongest points and can even reach a 90 degree profile. The knife has two separate

grinds and edges, one of them along the tip, and one along the major length of the blade.

Where the two grinds meet is a thin secondary point, and pressure can be brought down

on this point by applying force with the heel of the hand at the spine, useful for flat

cutting chores. The two edges in this particular knife are also straight, which

can make the knife easier to sharpen.

This particular tanto has a half-length top swage, to create a more easy penetration

without sacrificing too much strength of the tip. The serrations toward the hilt are individually

hollow ground and can saw through hardwoods with ease. The thumb rise has good placement well

forward of the front quillon, and the front quillon is reinforced with complete bolster coverage.

This is a version of the PJLT, my most popular combat tactical rescue knife, and is often made for United

States Air Force Pararescue personnel, as well as rangers, SERE professionals, and tactical emergency

response units.

Page Topics

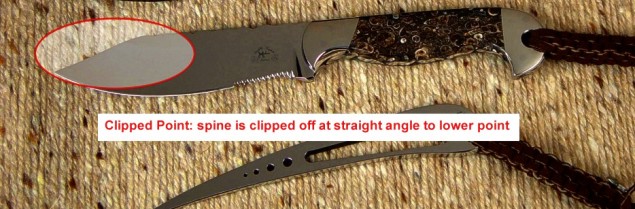

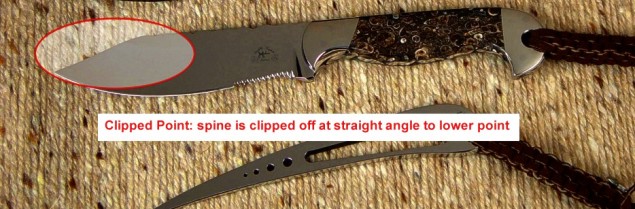

Here's a Clipped point (or Slant point) on a mariner's and sailor's knife.

The point angle is increased, making the point stronger than a straight point or trailing point.

The clip point can have a very thin and aggressive point with thin cross sectional area, yet

be easy to sheath because it drops lower than the main blade spine axis. This particular blade

is deeply hollow ground.

Note the small, regular serrations near the ricasso of the knife blade, the well-formed

handle shape, and the marlinspike/shackle breaker. This is a sailor's knife, the

"Mariner."

Page Topics

Here's a good example of a clipped point

with a swage. The point has been "clipped" off (common in Bowie

style blades) at a fairly straight profile to increase the acuity of the

point and is ground with a swage for a false or real edge. Though the

edge may be left unsharpened, if the grinding and finishing on this type

of knife is well-executed, it can result in a sharp, taper ground edge.

The clip and swage creates a very aggressive point, and the knife is

easier overall to sheath as the point is lower than the main spine of

the knife.

This particular blade has a bit of recurve, and a deeply ground belly. Note the radically

curvaceous handle, with a full forefinger groove supported on both sides by bolstered

quillons. The rear quillon for the forefinger is also called a sub-hilt. This is my

"Ladron," an artistic grade collector's knife

in a modern Bowie style with blued blade, engraved steel

fittings, and gemstone handle.

Page Topics

A spear point description was historically used to refer to a double edge, but nowadays it refers more

to the almost uniform profile of the point, whether it has two edges or not. If you were to bisect the

profile of the point, you would see a nearly symmetrical profile on both

sides of the blade axis center line, like a spear of old. In this knife, the top of

the spear is differentially hollow ground with a small contact wheel, creating a true

double edge for half the length of the blade. A very effective and

devastating grind for a combat or tactical knife blade.

This blade, like most double edged blades, should be left thick enough down the

spine to support the thinness that will result when the blade is hollow ground

from both sides. The knife blade should also be tempered properly to increase

toughness.

The knives shown are my

Prairie Falcon design.

Page Topics

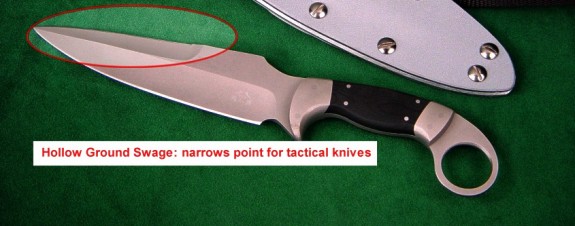

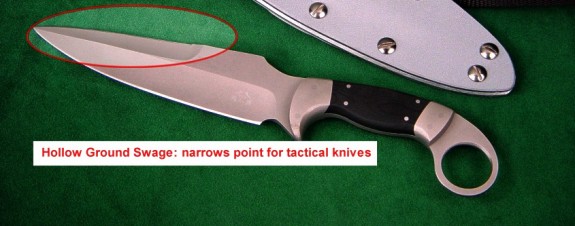

Hollow Ground Swage, Spear Point, Double Edge (Spear-Swage)

This knife's blade shape is not so easy to classify. It is definitely a spear point blade shape,

but the swage is actually hollow ground and is honed to a cutting edge. So you might want to

call this a dagger, even though it's not symmetrical. Another problem with that

classification is that the swage/hollow grind extends only along half the length

of the spine. This is considered a double-edged knife, thought the edges are not

completely along the blade. Classifying knives by blade shape alone is not always a clear task.

The knife illustrated here is my "Bulldog" a tactical combat knife. It has a very strong, stout thrusting

point for maximum penetration. Note the very wide and thick spine, and the strong choil

and forefinger quillon. The rear finger ring is for the forefinger, as

this knife is pulled out of the sheath and held in the tactical (reverse or defensive) grip.

Page Topics

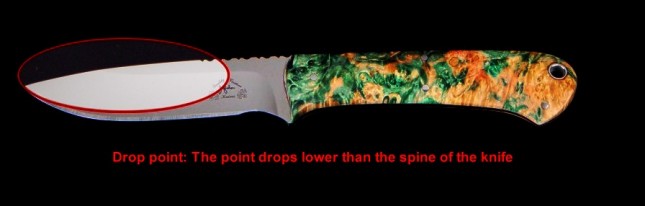

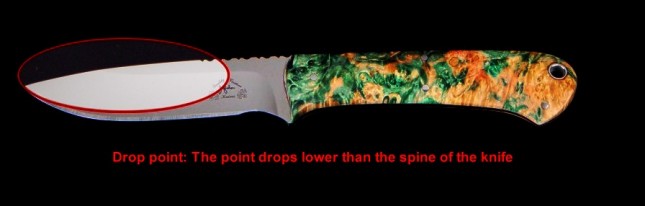

Here is a traditional drop point (or dropped point). The point is strong, convenient, and sheaths easily

which is probably its best attribute. One of the most popular point styles, this makes a great utility knife.

Note the lack of bolsters on this particular knife, and handle scales of

stabilized wood, which makes this a very light weight knife to carry.

The lanyard hole is lined with stainless steel or nickel silver, which

strengthens it and prevents wear on the wood scales.

A great number of sheath knives are drop points, it's a very popular

style, and the angle of the drop can vary greatly. From a slight drop to

radical downward curves, the styles of blade shape are numerous in this point

shape. Many modern hunting, field dressing, and skinning knives are drop points,

and many utility knives benefit from this type of point. Since the point is

the weakest part of any knife, the drop point blade shape is well-applied,

as it does not have a thin, narrow point that can be snapped off if lateral

forces are applied.

Mirach is a fine example of a small, utilitarian drop point blade style. I

have hundreds of drop point styles on the

patterns page.

Page Topics

Gut Hook on Trailing Point

The frontal gut hook is more of a feature than a description of a specific blade shape,

and the gut hook may occupy several predominant positions on the blade. Its purpose is to

split the skin of a game animal in gutting operations of field dressing by hooking over

the skin and fascia, and being pulled along to sever it. This particular gut hook is unusual,

because it's on a trailing point knife. The slight trailing point is not high enough to

interfere with the gut hook's operation.

The knife is my "Cabresto" design, with a sweeping, deep-bellied blade for fleshing and

a contoured and radiused finger grooved handle for control. The full tang knife has an extended tang with

a lanyard hole for security. This is a very early knife of mine, made back in the 1980s.

Page Topics

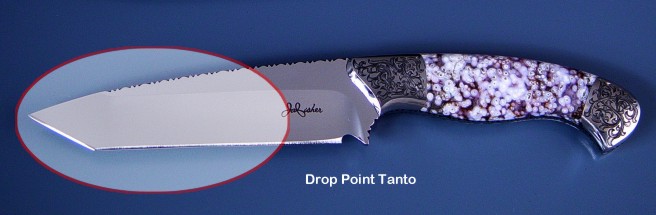

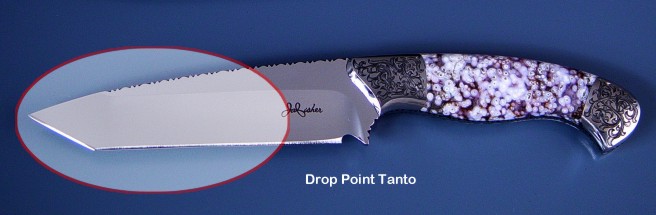

The tanto blade can have several variations, including in combination with a drop point. The drop point

makes the knife easy to sheath, and the angle makes the point physically smaller, but oftentimes

stronger if it is properly ground. For utility tantos, this is a great style, but it is beautiful

enough for fine collector's pieces.

You might be wondering about the two edges by now. Sometimes, depending on the maker,

his style and technique, these separate edges can be blended in the mirror finished form,

with such close geometries that a clear grind line is not easily discerned between the

two grinds at the cutting edge, but becomes more visible near the spine.

I believe that the tanto should never be ground without distinctive separate

grinds, always perpendicular to the cutting edge. So a rounded tanto point should

still have separate grinds, and if it doesn't, it's not technically a tanto.

The knife shown is my

"Alegre," and this one has a bit of an extended length blade.

Page Topics

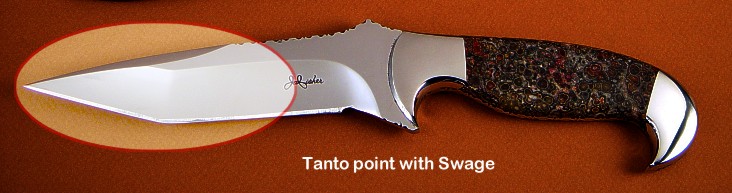

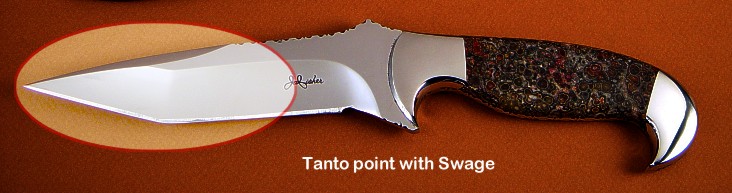

Like many knives, a tanto blade can sometimes benefit from the addition of a top spine swage.

The swage reduces the cross sectional profile of the spine at the tip, by virtue of

beveling both sides at a medium angle. I angle most of mine at about 45 degrees from the flat, which

produces a 45 degree beveled edge at the spine top and tip. Though you might think that

this is not very sharp, when smoothly ground and polished, it can

produce a serious point and tip. This aids in piercing, thus the common use of swages on military, combat,

and tactical knife blades.

This model is the Mercury Magnum, a derivative of a SWAT team design for

professional tactical use. In the photo, you can just see the grind union of the

two hollow grinds where they join the flat, but are blended near the cutting

edge for smoothness. This is called the dividing line or

yokote (definitions below)

Page Topics

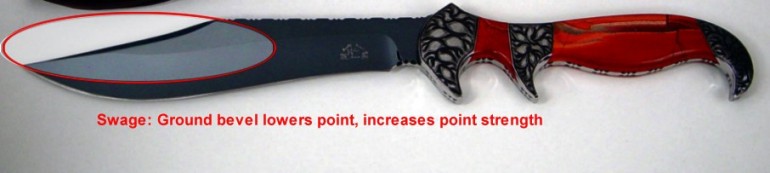

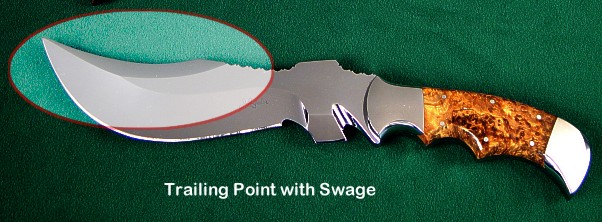

In special circumstances, even a trailing point can have a swage. The reason this is rare is because the

trailing point geometry is typically fairly thin, and the angle is usually sharp enough for piercing

if necessary, but the trailing point is not usually considered strong enough at the tip for combat tactical

use. Add the double beveling of the swage, and you have reduced the material at the tip considerably.

This can only be justified on special purpose knives, like the one shown, that are ground from very

thick stock, and are left thick at the spine. In a thick, heavy blade like this SERE (Survival,

Evasion, Resistance, and Escape) tactical rescue and survival knife, the geometry is carefully

controlled, and plenty of meat is left at the tip to support the bevels of the swage.

This is an unusual, unique knife that is tactical and defensive as well as survival-based.

The belly is sweeping, deep, and clean, a bit of recurve exists near the choil, and the blade has

a chisel cutter with flat spine impact area, and a line cutter at the ricasso. The finger grooves

are deep for security, and the rear bolster is substantial and strong. This is my

Flamesteed pattern.

Page Topics

The upswept drop point looks just like the description sounds. the blade is generally upswept like a

trailing point knife, which leads to a good belly shape in the blade which is great for skinning and

field dressing chores. Instead of a fine point at the trailing tip, the point is dropped down, rounded

over, or canted toward the axis of the blade. This creates a much stronger point than the trailing

point, which is much easier to sheath.

There seems to be quite a bit of confusion about the origins, name, and description of this blade

style, which is frequently called "Nessmuk." Nessmuk was the pen name of George

Washington Sears, a sports writer for Forest and Stream magazine in the 1880s. He took the pen name

from a Native American friend he knew as a young child. He wrote "Woodcraft and Camping" after canoeing and

camping extensively in the Adirondacks in 1884. Mr. Sears had a lot of experience with knives, not only

with camping, but three years on a whaling vessel. Mr. Sears preferred very thin knives, because these

are useable knives. He carried an axe for chopping, and a small folding knife for lighter chores.

It's clear that Mr. Sears did not design or develop this style of blade. Knives found in the hands

of the Plains Indians were made by Lamson and Goodnow (the oldest cutlery company in the United

States) as butcher knives are remarkably similar to the Nessmuk style. If the blade was repeatedly

sharpened, then broken at the tip and rounded a bit, it appears as Sears'

Nessmuk. History aside, the knife shape was popularized by Sears, and the name is neat, so it stuck.

A great example of a Nessmuk style blade is my

Pherkad in jade.

Page Topics

Dagger blade styles are very, very old. One might say that the propensity for double edges originated

in the stone age, and they would be correct. Today, daggers are simply double edged knives that are symmetrical.

Historically, daggers were used only as weapons and not as tools, but I've made some daggers that double for

tool use as well as combat and rescue.

Daggers are difficult and challenging to make, as four grinds must be uniform and equal. Fine daggers

are therefore a serious investment, and often worthy of the best handle materials. Daggers may be full tang

(like the "Classic" shown) or hidden tang. The blade should have substantial thickness in the spine, as grinding

away much of the mass of the blade can lead to a very thin piece of steel indeed! Planning and execution of a fine

dagger should be a carefully thought out affair. Grind terminations should be well radiused to prevent stresses

from concentrating at the blade to handle junction, and axis lines should be well matched.

See some fine examples on my Daggers page.

Page Topics

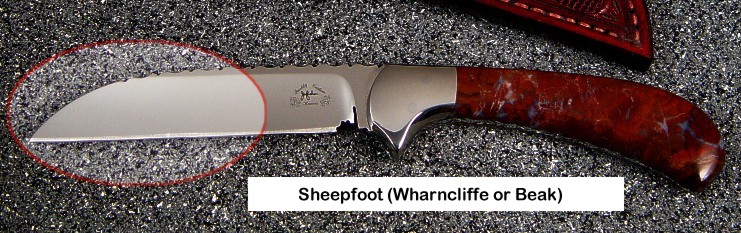

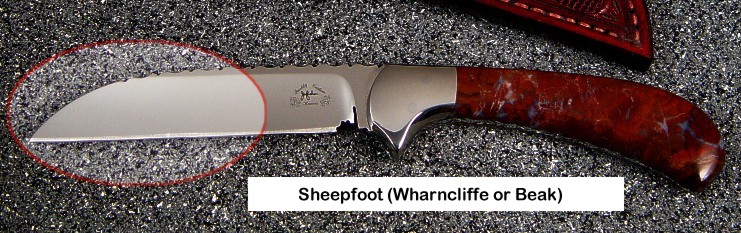

This style of blade point has had several different names throughout history, but they all mean the same general

thing: the cutting edge is fairly straight, and the spine and point are rounded

convexly downward to meet the point. This is a very strong point for bearing down and applying

pressure from the spine of the knife for cutting tough textiles, carving wood, or any chore

where a lot of pressure will be applied. Having a straight edge can also aid in

sharpening, as flat stones may be easier to position and hold to the correct, uniform angle with this shape.

It is generally accepted that the dropping geometry of the point is more

abrupt in the Sheepsfoot style than the Wharncliffe, but both are

very similar, and these distinctions of name are entirely subjective. A

maker or manufacturer may call his knife blade style by any name. It's

interesting to note that in the photo at the left, the geometry is

typically between the Sheepfoot and Wharncliffe styles.

Here is another historical curiosity about the name of this point. In current times, it is common to call this

type of point a "Wharncliffe," a name originating from a claim that the Earl of Wharncliffe actually developed

this point. . This is incorrect, as this point shape has been used since Roman times.

I wonder what the ancient Romans called the point. "Wharncliffe" seems to be more

linguistically appealing than "Sheepfoot" or "Beak" which are

technically more descriptive and historically appropriate... such is the romance of knife making.

The pattern is my

"Falcon" design.

Page Topics

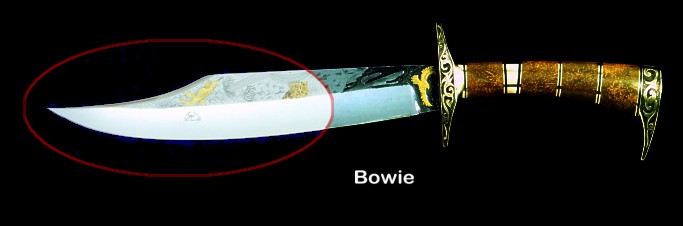

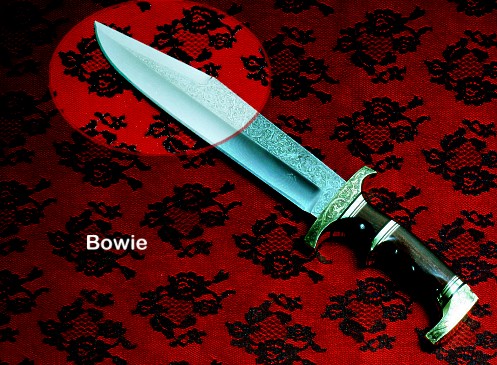

Not specifically classified by the tip shape, the Bowie knife is an American standard, historically recognized, though

not always clearly defined. Technically, most Bowie blade shapes are clip points,

most with a concave clip that may or may not be swaged, sharpened, or ground. In reality, any

large, heavy weapon-type knife that resembles period knives from the 19th century are called

Bowie knives. There are volumes written on the subject of Bowie knives, and many conflicts

in the description alone. I inserted this blade style in my shape classification simply because

it deserves the historical respect.

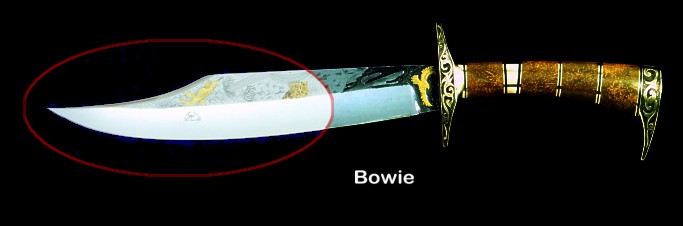

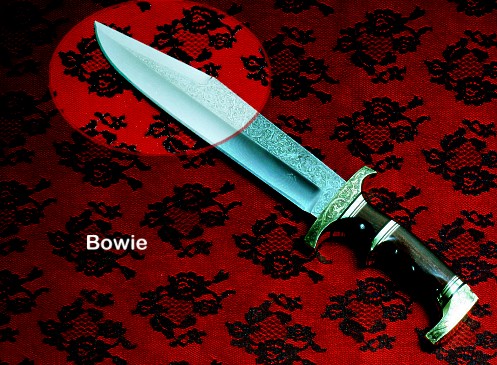

In the top picture, the Bowie has a concave clip point with a swage.

The bottom picture is a Bowie with a straight clip point with a hollow grind.

Page Topics

One would think that detailing the position and view of a

knife would be a simple thing, but a number of terms have developed

in the English language for areas, locations, and views of a knife.

Most of these have their roots in history and convention, and a few of them

are contemporary. A knife is not a vague object; in our history and humanity,

the knife is the oldest tool and deserves special consideration in high

detail.

Below is a photo set of one of my knives detailing and describing

those names and descriptions. I've included a few terms relative to the

knife sheath also. The

knife I chose for these descriptions is my

"Alegre" pattern, a

tough, working tanto style blade, mirror polished high chromium

stainless tool steel, sculpted stainless steel bolsters, and

Polvadera Jasper gemstone handle.

Knowing the location of a feature of a knife is important. Not only does it

aid in describing, illustrating, or detailing the knife and its features, it

builds a foundation for conversations about the knife. In the custom knife

world, conversation is everything, and understanding the location and area

will help in those conversations, enabling the description and creation of

a fine knife.

If you might wonder why knowing these terms is important, at the

bottom of

this section is a testimonial describing the very knife I've detailed. Mr.

Kramer, an artist and dedicated knife user, has designed this popular knife in conversation

with me, and this would not be possible without knowing the terms and locations

on the knife.

Page Topics

I freaking love you man, I don't know if you're even alive given that your website looks ancient,

but I came across your Knife Grip page while I was doing some research for a fight scene I'm writing

out, and your educational pictures made things so much easier to understand than what I found on

Wikipedia.

I don't really want to buy a knife, but thank you for the educational images.

--Adam

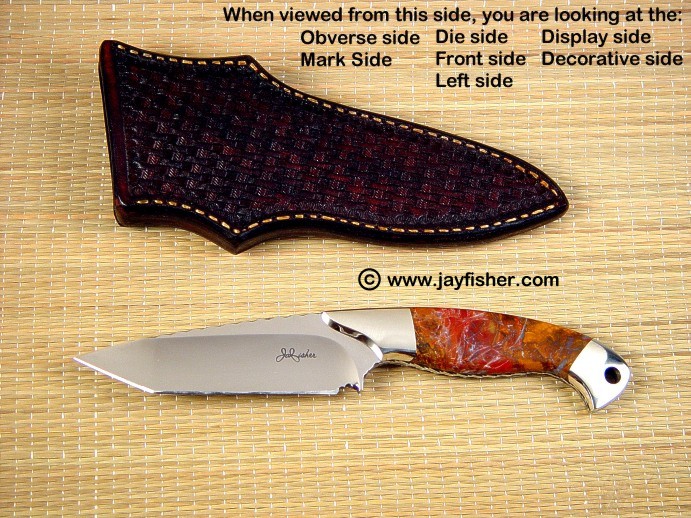

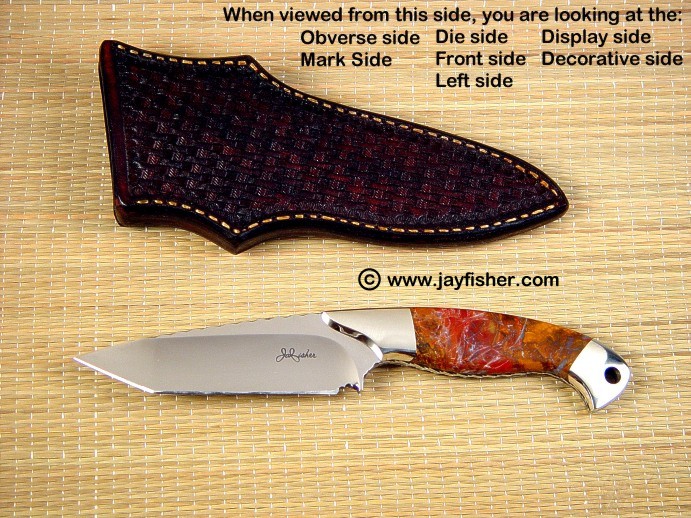

This is a view of the Obverse Side. There have been many names developed for this side of

the knife, and in my upcoming book, I detail where those terms came from. It is

an interesting history, with ties to other metalworking trades and

industry.

This is the most commonly viewed (or observed) side of the

knife nowadays, because it is the side that bears the maker's mark. So,

it's also called the Mark Side. When the knife is held in the

hand, with the blade pointed away and the edge down (always a good

safety practice) this becomes the Left Side. Since it is mostly

photographed, it's also the Display Side, and often the

Decorative Side. It's also called the Front Side and

Die Side. These terms may not be all this side is called, but they are

the most common in our industry. This favored positioning is derived, I

believe, from the majority of people being right handed, and I go into

much more detail in my upcoming book.

At the very minimum, this should be the dominant and available

photograph of the knife. This is because history and convention

dictate that the maker's mark be visible in the primary photograph,

and an unmarked knife is a valueless knife.

More about knife maker's marks.

Here's another version of my Alegre knife pattern.

Page Topics

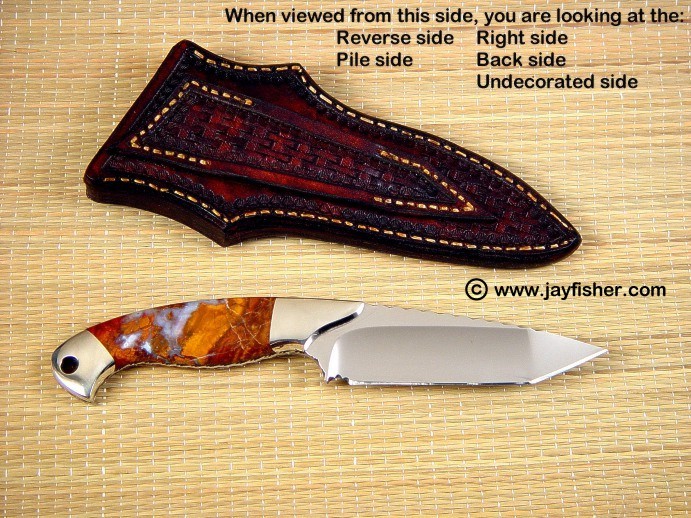

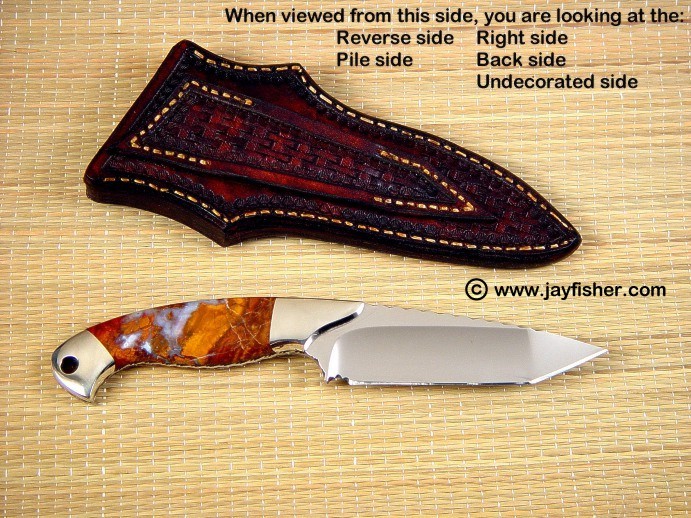

This is a view of the Reverse Side. Just like the Obverse side, there

have been many names developed for this side of the knife. This is not

the most commonly viewed side of the knife nowadays, because it usually

bears no marks or identifiers. It's also called the Pile side. I

won't tell you here why that is, it is a neat curiosity that I detail

in my book. When the knife is held in the hand, with the blade pointed

away and the edge down (always a good safety practice) this becomes the

Right side. Since it is the least photographed, it's also

called the Back side, and also the Undecorated side.

This is the orientation that I photograph my

patterns. The reason is

since we read from left to right, I align the pattern handle butt

with the scale, and measurement of the handle and blade is simple and up

the ruler.

Just because this side of the knife is called undecorated and

reverse, this is no reason to give it any less importance than the obverse side. Because

the reverse side is usually bare on the blade, it becomes a significant area

for etching, engraving, or personalization of the knife blade. If a knife is

commemorative or marked on this side with name, campaign, or other personal

significant text or graphics, it can be more important to the owner than the

obverse side!

I always include the sheath in the photograph of this side if possible,

as the back of the sheath is as important to the front in finish, style,

decoration and embellishment. More important than that is construction, as

the belt loop size, placement, and mounting method should be displayed.

Here's another nice "Alegre"

Page Topics

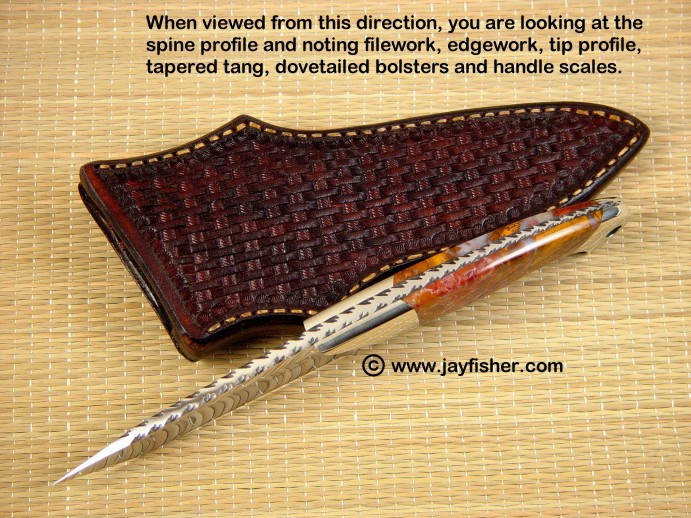

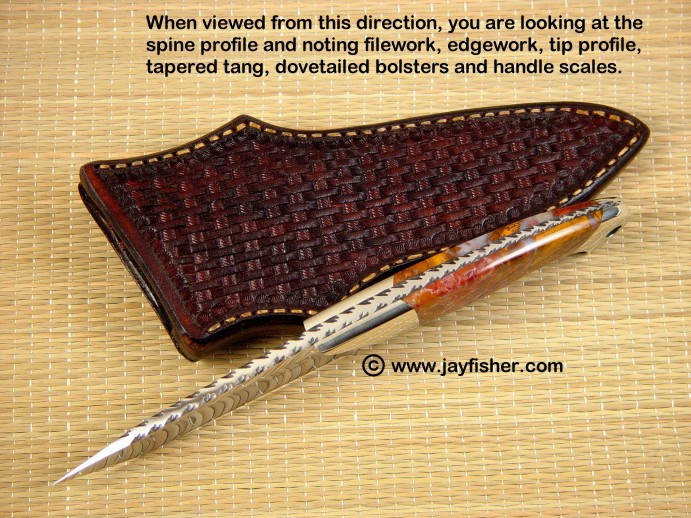

This is a view of the knife spine, so named since the strength of the blade is derived

from it. It's actually the spine profile since looking down on the spine allows you to

see its profile, thickness, grind geometry, tang shape and size, length, and finish.

This side is also sometimes called the back, but this is an antiquated

term that is best avoided, so as not to confuse it with the back side of

the knife blade (the reverse side).

In modern knives, this is a very important view

to illustrate, as it shows the relative thickness, cross-sectional

geometry of the knife blade and point, the bolster or guard profile, the handle

thickness, and the tang geometry. This photo is of a full tang knife

(a solid piece of steel from tip to tip) and the tang is tapered for

weight balance and high quality construction. Note the dovetailed

bolsters, for a rigid and bedded fit between bolsters and handle material. This

view is also important to identify the edgework and filework, which has

developed into one of the key indicators of fine quality knives made in

modern times. More details on filework on my

Embellishment page.

Page Topics

It's important in modern

knives that have accessories (sheaths, stands, and cases) to include a

view of those components too, and how they relate to the knife. For a

sheathed knife, this view details the relationship in size between the

knife and sheath, the position and extension of the protruding handle,

and the handle components that will help a knife user extract (or pull)

the knife from the sheath. Here you can clearly see that the rear

quillon (or hawk's bill) aids in extraction. You can get an idea of how

many fingers can be wrapped around the handle for the pull. This knife

also has a lanyard hole through the bolster and tang, so by adding a

short, stout lanyard, even greater ease of extraction and security can

be gained.

The sheath is more important than just someplace to carry the knife.

If the knife is carried, it will be the sheath that takes the brunt of

wear and exposure, and it is the sheath that will have the highest

visibility and dominance, not the knife. Since the sheath is part of the

knife and part of this tradecraft, I believe it is essential to create

custom sheaths that are commensurate with the value, theme, embellishment,

and quality of the knife. I go into greater detail about knife sheaths on my

Sheaths page.

Page Topics

More

More about Chef's

knives

You might wonder why it's important to have a comfortable knowledge

of knife parts, components, sides, views, features, and how they are named. The best

reason is that if you ever want to own a fine custom knife, and have significant input

on its design, materials, embellishment, and accessories, you'll have to know enough to be

able to converse with the maker of the knife.

Below is the result of just such a conversation. Mr. Kramer is an artist

and craftsman in Taos, New Mexico, and wished to have his own, custom made,

unique and original knife to carry and use. The conversation started and

points and features were detailed, and the knife construction began. Mr.

Kramer offered various suggestions, preferences, and wishes, and I did my part

trying to create his vision within the scope of the project. The Alegre is

the result. The name means bright, cheerful, colorful, and light.

The design lives on, long after the first knife is made, and I've made

more and different Alegre pattern knives and will continue to do so, as

it is a great pattern. One of the finest aspects of the knife maker-to-client relationship is the passion

demonstrated and continued long after the knife is sold. Below is a

vignette into that experience:

Page Topics

Jay,

Well, Jay, now I’ve got a problem. I ordered the knife as a daily

user, to carry with me always – my third hand. Now that I have it, I

see it should be displayed on a shelf as a work of art!

When I saw your picture of the knife, my mouth dropped open. Now that I actually

have it in my hands, the reality of it takes me to an even higher

level. I am overwhelmed. What extraordinary quality and workmanship.

And the balance... I don’t hold on to it, it clings to my hand,

resting there as if it always belonged. You really put

yourself into it. I’m speechless… but AWESOME (in a very loud

voice) comes to mind. You truly are an artist and a knife

your canvas. But, I am going to follow through and carry your

artwork with me every day. A knife needs a hand to make it whole.

It’ll be a good friend.

Let me give you some first impressions of specific aspects.

I read on your web about “balance”. Now I truly understand. Alegre

is a knife with a little heft for its size, yet it’s so balanced in

my hand. I also love how the handle belly, the upper arch on the top

of the handle, the hawk bill quillon on the rear bolster and the

quillon on the front bolster conform to the hand. The concave forward

extension of the front bolster turned out well.

Aesthetically it adds to the gentle forward sweep/curve of the

knife. It also works well as the thumb rest. I wondered if the

filing through the thumb rest would aggravate the thumb, but you

don’t even notice it. I will be enable to place a lot of thumb

pressure to the job.

The mirrored finish, what can I say -- thanks. It takes the knife up

to a whole another level. I cannot imagine it without it now.

I’ll say it again; your signature in the blade is perfect. An artist

signing his work.

The dovetailed gemstones and bolsters shout quality. The fit you are

able to get throughout the knife is unbelievable.

The filing is awesome. (There is that word again.) I didn’t realty

expect to get something that special. I love how it goes the total

length of the spine to the grind termination. The thin triangular

slice in the tip of the spine seems an extension of the filing; like

the tip of an arrow. It is wonderful how the filing narrows down as

it goes toward and through the rear bolster and yet you keep the

pattern going. Then it slowly dissipates, as if through years of

wear, at the front quillon.

Thanks for the filing in the choil. I didn’t expect that but I

really wanted it. I think it adds so much to the style of the knife.

The sheath is amazing all in itself. The basket weave

is perfect. It oozes quality but does not shout.

And then you threw in the extras. The museum display tag is a great

idea. The CD of all your knives is appreciated. Thanks.

New Mexico…

You know when I found out I’d priced myself out of the original vision of the

knife, I was a little depressed. But your insights were helpful and

right on. I could not afford that much right now and I would have

never used as a daily knife.

BUT... you still created a knife that reflects our wonderful state. Here is what I will see every time I

look at it:

- The gentle arching top/spine is a broad, expansive NM horizon. The

forward sweeping concave front bolster, grind radius and tanto point

further accent that.

- The hawk bill rear quillon with its “eye” brings to mind NM wildlife.

- The Polvadera jasper you chose is perfect, maybe even more than you

realize. I love all the veins and various earth tones. The warm

color of the nickel bolsters blend marvelously with the gems. There

is a nice depth to the stones. You look into them. That adds a

richness and mystery. They remind me of the geology in NM.

- The left side gemstone, the one in your picture, has the red of a NM

setting sun. When you turn it over there is the white of the NM snow

topped mountain peaks. And then being an actual NM gemstone makes it

really special. Here’s a toast to the Polvadera mountains.

- And then, of course, the filling is the lightning (what a great name

you chose) from our summer thunderstorms.

ALEGRE ! ! !

--Carveth Kramer

Taos, New Mexico

Special thanks to J. S., forensic physician, and to all my forensic pathologists

and researchers that are interested in knives!

Because knives are objects with many features, it's critical to present them, whether for purposes of record, illustration, description, or advertising,

in various viewing positions. As described in the previous section, the

predominant view in the United States culture is of the obverse side. This is largely

because of the typical right-handed person's perception of the knife, and because in America, this is the location of the maker's mark.

Because knives have

many worked, figured, embellished, and interesting features, it's essential to photograph or view the knives from various perspectives to achieve a better

understanding of the entire piece.

The cost of photographing a knife professionally is traditionally high. I'll go into this more in my book, but often knifemakers do not photograph their

own work, leading them to seek out professional or at least skilled photographers to accomplish this for them. These photographers are usually

commissioned for

a singular work, that is a key shot that the maker can use to illustrate and often sell his work. Since it's only one photo, it is severely limited in what

is illustrated. Photographers understand this and typically use a computer resident photo

manipulation program (Photoshop, Photopaint, Adobe, or others) to join

at least two different perspective photos of the knife into one photo. Typically, this is the obverse side and the spine, but may also be the obverse side and the pommel, or the

guard, or a close up of the engraving, or whatever feature the knifemaker and/or photographer agree looks best for the piece. This practice has become the standard

descriptive method for knives being recorded, at least by professional photographers.

It's important to understand the limitations of this method. Perspective is one, and simple lack of details is another. Another limitation, most critical, is

that there are areas of the knife (and often sheath) that are not illustrated at all, therefore, the person viewing the knife simply does not know what the reverse side

may look like, or the full handle periphery, or the engraving except in a general way, because the photo is not an

enlargement. For advertising purposes, the knife

photo involves a great deal of trust in the appearance of the rest of the knife, the parts one can't see from the

provided photo.

Limiting the photography makes sense from an economical point of view, but the internet has changed all that. It is

essentially inexpensive to offer, record, and maintain

an archive on the active web of numerous perspectives and positions of the knife, and that is exactly what I try to do when I photograph my own work. This

offers an

unquestionable illustration of the knife for the person who is interested, or who may purchase the knife, and this includes

sizable and detailed enlargements and magnifications

of various parts and areas of the piece. Who wouldn't want to see a four or five power enlargement of

the engraving?

The positions of knife views then become (in the knifemaker's world) important to the record, and there must be some simple and plain way to describe them, so that

the person viewing the knife photos will know at what, exactly, he is looking.

This is not a complicated method, though it could become quite confusing

and overburdened with terminology, reference, components, elements, and

details. All of this extra and elaborate language serves only to confuse

what is, simply, a view position of a knife. For a ridiculous example of

this overly descriptive and embellished text, see the term

distal below.

The obvious and clear method to describe the viewing position of the knife is to name it for the predominant

feature that the person seeing the photo will notice.

For the obverse side view, the text labeling the photo should clearly state that it is the

obverse side view. Same for the reverse side view. These are clear enough.

In viewing positions other than those, there are two possible choices. One is to describe the location seen as the viewing description, such as

spine view, or inside handle tang view. This descriptor clearly associates the person viewing the photo with the predominant component. Other positional view descriptors would be

pommel view, or sheathed view. These are simple descriptors that will

familiarize the person investigating, describing, and presenting the knife with the components.

The second method of describing the view position is one of features. The person presenting the photo may use this to

method to describe the predominant artistic or structural

components of the knife (or sheath, or accessories) that he wishes the viewer to note. Often this is an enlargement of the actual area of the knife, so I typically

accompany the descriptive text with the word detail. In practice, then, I'll refer the reader and observer to the filework detail

or obverse side rear bolster engraving

detail, or inside handle tang detail, or reverse side

gemstone handle detail. Simply put, if the word detail is used in the descriptor, it means that the photo does not encompass the

entire knife at full perspective, but a portion of the knife the presenter wants to illustrate.

These terms simply describe the locations, features, and details of the knife. The human mind then can fill in the rest, knowing what they are looking at from the description of the knife

locations. See some examples below.

Page Topics

Viewing Position Description and Illustrations of this "Thuban"

Obverse Side View

Reverse Side View

Spine View

Inside Handle Tang View

Obverse Side Handle Detail

Reverse Side Handle Detail

Obverse Side Front Bolster Detail

Obverse Side Rear Bolster Detail

Obverse Side Blade Detail

Point Detail

Sheathed View

Sheath Front Carving Detail

Another Nice Thuban:

More

More about this Thuban

Welcome to the best, most detailed, and largest knife definition terms list available in the world!

Current count: 331 terms!

Definitions and terms of knife parts and components have varied

through time, and you may repeatedly see the same commonly copied lists of knife definitions

that have been cut and pasted on many internet sites. My list is not

one that will be easily adapted for everyone's use (and this site is copyright

protected!), but I'll do my best to define some standard knife terms from the

viewpoint of a current professional knife maker, and stay away from vague

generalities you'll see all over the rest of the Internet. Some of the terms

listed previously on this page may not be included here, as they are already defined in the above

text.

Describing the knife is an overlooked facet of this trade and

industry, yet it is probably one of the earliest conversations known to

man. Definitive terms relating to hand knives (excluding specialized, industrial, agricultural,

or manufacturing knives) have varied origins and history. Simple terms like

blade come from European

languages meaning leaf. Other terms like choil, have an unknown

origin, yet apply widely to knives in many cultures.

Terms of identification and description change and evolve over time, depending on the language

and the culture. If it's significant, I've tried to add a little history explaining that. New terms

pop up too, and will continue to do so. I've also included some

misnomers in the list, which are misleading and incorrect names for some

of the knife components because it needs to be clear that these terms

are not new terms, they are significant errors. You might be surprised

at who is using these incorrect names, and this does our tradecraft no

good.

It's important to note that my source for language originates in English,

specifically the English language spoken in the United States of America. This is different, in many ways, than

English spoken in the United Kingdom. Here, you are on a USA website, so I do not recite the UK-produced Oxford

dictionary, but instead the Webster dictionary which originates in our language and is distinctly separate from British

English. These definitions are in American English, not British English, so please don't write me and tell me my

dictionary, definition, or terminology is wrong because it's not what they speak in the UK. Don't list or send me

sources of the Oxford dictionary; my heart is with Noah Webster, an American revolutionary who labored tirelessly to better

educate and improve the specific English language of America. So, in my own life, I embrace the liberty to use the

American dictionary, Webster's dictionary, as my resource and reference.

I prefer the color gray to grey, and in my shop, I prefer an American clamp to

a British cramp. We also say that something could be ground down instead of grinded down.

"England and America are two countries separated by the same language."

--George Bernard Shaw

1951

"Language as well as the faculty of speech, was the immediate gift of God."

--Noah Webster

1758-1843

You might wonder why go into such detail about words, after all, the knife conversation is fairly simple. Please indulge me

while I illustrate: Three top search terms people use to find my website are design, pattern, and template, all

preceded by

the word knife. Nearly all of these people want the same thing, but these are not. A

design is the concept that is formed in the mind, in

our case about the entire process, project, materials, execution, and completion including record. The

pattern is a guide to the idea with all its

parts (there are many parts to the simplest of knives, including fittings, sheath, stand, and accessories). The

template is the flat panel itself

that is used to scribe out the profile of the knife on the billet. So, the design creates the pattern which is made solid in the template. The design

is the idea, the pattern is usually drawn in two dimensions, and the template is the piece of plastic, metal, or wood actually used to lay out the

knife profile. And you thought it was all so simple!

In the definition list, I've also started including some business terms that illustrate some of the practices,

directions, and pitfalls of this tradecraft. Though I won't mention companies and interests

by name, if you're reading this, you're intelligent enough to understand who and what I'm

talking about.

Malapropisms: this is an important word, and it's not part of any knife! It is defined as

incorrect usage of a word by substituting a similar-sounding word with different meaning.

The reason I've included this is because it happens a lot. Knife makers, knife manufacturers, and

knife enthusiasts will often make this error, and when it occurs, I'll do my best to point it out

so that you will not be confused. I'm not trying to police other people's language, but in order

to be crystal clear in my service to my tradecraft, industry, and art, I believe it is critical

that the language of knife making be as direct, correct, and error free as possible to avoid confusion.

Take a look at the definitions of the word pintle and

pontil below to understand why.

Neologisms: these are new words, often combinations of existing words to describe a unique term. The word

filework is a perfect example. File and

work are two separate words but when they are combined and applied

to the field of knifemaking, they become a new word that describes a very specific and unique feature of

knives. By the way, the words knifemaker and

knifemaking are also modern neologisms.

Colloquialisms: these

are words or phrases that are not used in formal, written texts, and are

conversational only. Why do I include these? Because this site is

written as a definitive, specific, current, and accurate text in the

handmade knife professional field, that's why. I don't want to encourage

sloppy, local, descriptive, and lazy text or speaking when I teach

knifemaking to others; this does our tradecraft no good. While I may use

these myself from time to time, I'm always trying to police my language,

and if you are reading this, chances you are too, which is a good thing!

Abbreviations and Acronyms

and Initialisms:

these are different, but I won't go into specifics here. They

are composed of the leading or dominant letters of words or phrases to

shorten their length, and the ones included have a relationship to our

tradecraft and profession. Strings of letters like HRC (Hardness,

Rockwell, C-scale) are actually initialisms, not abbreviations, since

they are the initials of the words that make up the term.

Don't worry about using the wrong word or phrase if you contact me about a knife project. I'm expected to know these terms, not you; I fly the plane,

you just tell me your origin and destination.

Please remember: all of the text and definitions you see are written by me, one keystroke at a time,

using my own experience in this field. I'll amend this page and list continually, as nothing

on the internet should remain static.

Page Topics

Warning: Copyright details at the bottom of every page

- Definition List Alphabetic Links:

A B C

D E F

G H I

J K L

M N O

P Q R

S T U

V W X

Y Z

- Page Topics

- A

- AES

- The Abrasive Engineering Society is the source for technical information on all types of abrasives,

particularly grinding wheels and coated abrasives. Over its 60 years AES has been on the forefront of

grinding technology building a vast library of literature on evolution of modern grinding technology and a

knowledge base at core of modern day practices. It disseminates technological information, publications,

and information about modern abrasives technology worldwide.

Alphabet Links

- AISI

- The American Iron and Steel Institute. This society covers key public policy issues,

manufacturing technologies, commercial research, market development, statistics, and communications for

the iron and steel industries. AISI standards identify and develop steel information and specifics. They,

along with SAE, are the source of steel designations.

Alphabet Links

- ALICE

- This is not the little girl in Wonderland! This is the

acronym for All purpose Lightweight

Individual Carrying Equipment, the Viet Nam era system for carrying and wearing small equipment

on the body in the combat field. Though ALICE equipment is still around, it is being replaced

by the more modern PALS webbing on MOLLE gear. Most of my tactical knife sheaths will fit the

ALICE belt with the eyelets, by removing the aluminum belt loops and reattaching them over

the belt.

Alphabet Links

- allotropes

- From allotropy, and the Greek words allos (other) and tropos (direction, way). So it's the other way. Allotropy is the phenomenon of

materials with the same elements or compound to appear in different forms. A good example is carbon; it can be a piece of graphite (extremely soft)

or a diamond (extremely hard): it's all still carbon. In the knifemaker's world allotropes are important variations of steel when heat treated.

Allotropes are austenite, ferrite, martensite, and bainite, all existing (or not existing) because of proper (or improper) heat treating.

Alphabet Links

- alloy (steel)

- A substance composed of two or more metals intimately mixed and

united. Typically, in knife blades, these alloys are included to

enhance mechanical properties, aid in fabrication characteristics,

and add specific attributes to the steel. I use a dozen different alloys in my

current work; all of them are hypereutectic and high alloy tool steels and stainless steels.

Alphabet Links

- AMS or SAE/AMS

- Aerospace Material Specification. This is the SAE International, AISI standard designation and specification system used to identify specific