Jay Fisher - Fine Custom Knives

New to the website? Start Here

"Raptor"

This page is directed to the counterterrorist professional. Whether they are called counter terrorism, counter-terror, counterterrorism, or CT knives, whether for full combat wear or PSD (Principal Security Detail) professionals in a full business suit, this page is about these very specialized knives, their features, their differences, and useful comparisons to help the counterterrorism professional understand what may be possible, what to look for, and what to expect from my studio.

A real counterterrorism knife is a knife designed with the input of, built for, tested by, and used by the top counterterrorism units in the world for their daily professional use in handling, disarming, and eliminating terrorist threats.

All of these knives are in service in the counterterrorism

field: in the hands

of military counter terrorism teams, intelligence officers, and police

special units. Some are in the hands of investors, advisers, and

training and support

groups.

They are made with direct input of these professionals.

It is a huge honor to have made military and combat knives for decades, because these are the most serious and critical of operations. Most of these knives were created with the direct input of the individual combat or rescue professional. Like the knives I make and have made for the United States Air Force Pararescuemen, Combat Rescue Officers, Combat Controllers, Tactical Air Control Parties, military and law enforcement professionals have special needs. I've also made custom combat knives for United States Army Intelligence, United States Army Rangers, and United States Navy Marines and SEAL team members. They include Homeland Security, FBI, and MERGE and SWAT team members in law enforcement. I've also made and continually supply many specialized knives for our allies. You can see hundreds of examples of them on my Tactical and Combat Knives page.

It was only a matter of time before I was contacted by representatives of an Israeli Defense Force/Israeli National Police YAMAM counterterrorism unit, widely considered to be one of the very best counterterrorism forces in the world. They specialize in counter terrorism, hostage rescue, offensive take-over, SWAT duties, and undercover operations, and specialize in Close Quarters Battle (CQB). There are some simple reasons these professionals have come to me:

I directly confer with them to make them the gear they need, and it is a tremendous privilege. Many of the knives you will see here are made for the YAMAM unit, which is as serious an application as there is. These knives are in the field, in action, in operations, missions, and heavy use of the most serious type. I'm humbled and honored that they have chosen me for their needs, and I have continual evolution of these counterterrorism knives, designs, features and accessories in the works.

"Jay Fisher is the best modern knife maker around, pursuing an ancient tradition but beautifully perfecting the craft by selecting the finest man-made and natural materials. Jay makes every type of edged steel weapon, fitting the blade to it’s purpose. The world’s elite clandestine rescue and tactical squads seek his weapons. Their lives depend on Jay Fisher Custom Knives- the best quality knives in the world."

--Bernardo M. Perez

Deputy Assistant Director-Ret.

FBI Laboratory

Washington, D.C.

There are organizations and operatives that are simply unlisted. And so are their knives. If you are one of them, you know what to do; I offer Professional Knife Consultation, and I'll be happy to work with you to get you the essential edged gear you need. Email.

Please remember that I offer Professional Knife Consultation, as well as the finest handmade custom knives available.

Everything I offer is handmade, and most of it is custom. There is not an assembly line movement of knife projects in the studio, but I can (and have) made small groups of custom counterterrorism knives for complete Units. The CT units get my specialized attention, and every single knife is treated like a unique and critical piece. Every grind, every part, and every component is meticulously hand-fitted to the individual knife.

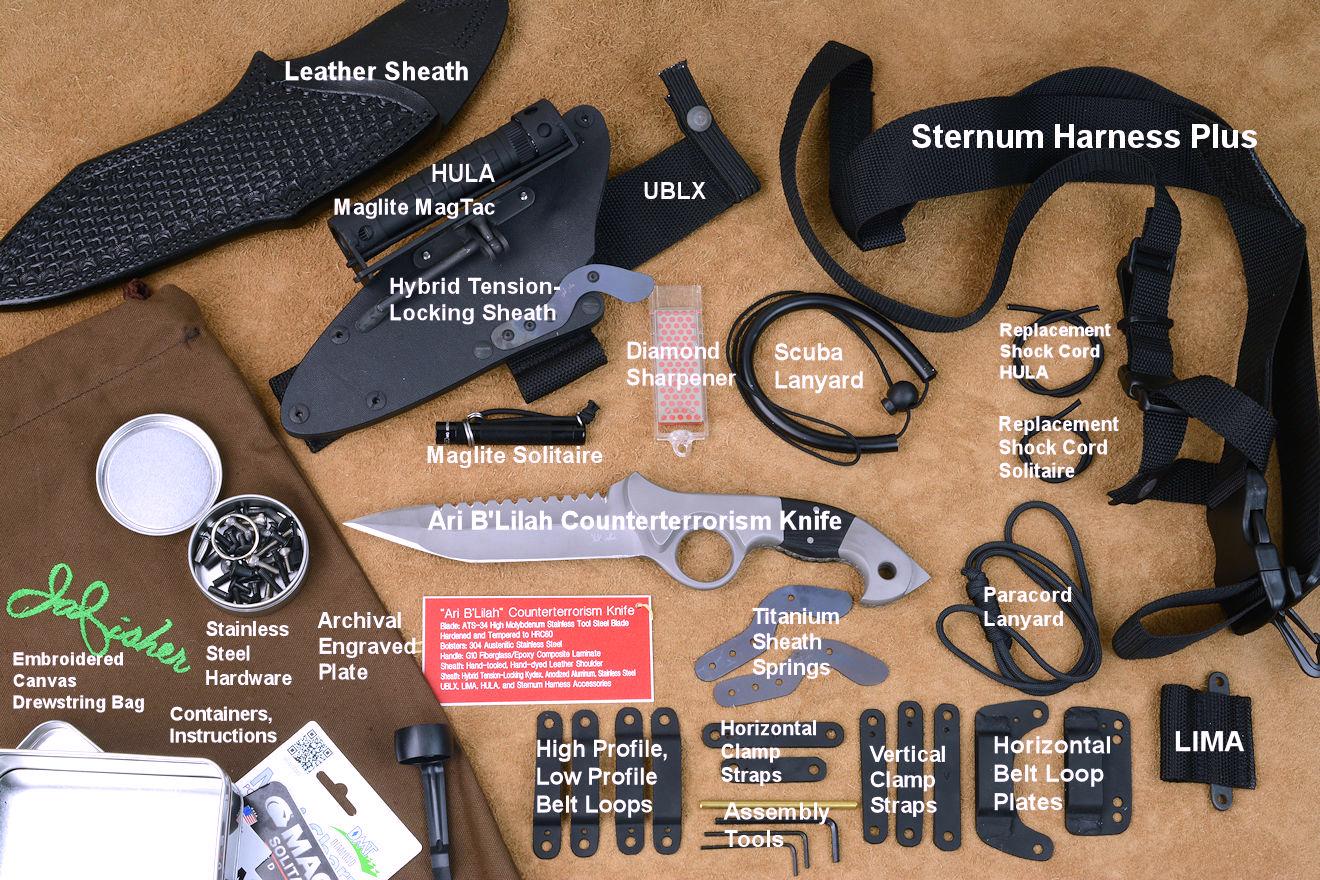

In this photo group below, you'll see a group of "Ari B' Lilah" (Lion of the night) counterterrorism knives I made for a very special Israeli Defense Force/National Police Force YAMAM counterterrorism unit. They had direct input on every part of the package; telling me what they needed for their most critical of operations. You'll see the blades roughed out, in ATS-34 high chrome-molybdenum stainless tool steel, the bolsters before and after mounting, in 304 austenitic high nickel, high chromium stainless steel, the handles in G10 fiberglass/epoxy composite, and the large assemblies of hardware for the sheaths and packages in 304 stainless steel, high strength corrosion resistant 5052 aluminum alloy, double thickness kydex, titanium, polypropylene and the accessory packages. You'll see the additional leather sheaths, required for quiet operations where metal hardware might make a noise. The packages allow a huge number of mount and wear options, and each counterterrorism professional can set up his rig to match his gear and mission.

Every single piece is handmade, and this constitutes a tremendous amount of work. I'm proud to say this is all mine, and it was a great honor to make this (and other) groups for the finest counterterrorism units in the world.

Since counterterrorism professionals tell me what they need to do their job, it's sometimes necessary to build prototypes of various models including all of the necessary hardware for critical wear and mounting options, as well as all the accessories. This is not a job for the timid, and just for detail, here's a photo of my main bench after a session of building one of these prototype sheath accessory kits.

...and yes, I know where everything is!

An important part of counterterrorism operations lies in the protection of individuals, specifically heads of state, dignitaries, high-ranking public officials, and the wealthy. They are terrorism targets, and there are specialized counterterrorism individuals and teams that are dedicated to their protection and care. In the old days and for common consumption in Hollywood and the media, they are called "bodyguards," but today the professional is part of a Principal Security Detail, or Personal Security Detail, often simply called the Security Detail. The principal is the person, family, or group that is being protected, and detail professionals are responsible for a great many factors such as travel, exposure, scheduling, routes, and electronics. Since they are professional, it makes sense that many of them are armed, and knives are part of the weapons available and necessary for their professional counterterrorism use.

When one thinks of tactical combat knives, the idea of the flat finished, darkened, plain piece of steel in a dull sheath is the usual image. But what does a professional wear who dons a three piece suit? Now that protective armor comes in stylish ensembles, why is it necessary for a knife to be flat, ugly, and plain? I realized this when I started making knives for professionals in PSDs, as they asked for knives that were as beautiful as well as functionally defensive. They asked for smaller sizes, low indication profiles, and specialized harness, wear, and accessories critical to their needs. This field, like the overall counterterrorism field is certain to grow, and since a finely made and effective defensive knife in a suitable wearing ensemble is not manufactured, anywhere, the custom knifemaker is the only place that this assembly and tool set can be made.

There are many critical features for the PSD counterterrorism knife, and as I continue to build these security detail knives, my clients direct me to more critical and effective designs, types, and accessories, and I'll post some of them here.

One of the most important features of this type of knife is the sheath, like all true combat and counterterrorism knives. An effective defensive weapon is not carried folded up in the suit pocket; it's worn beneath a suit, behind the back, or in a dedicated harness that is not ordinarily visible. Horizontal wear, vertical or angled wear or harnesses at the sternum or back are often asked for. Often, leather is requested to be undyed, unsealed, and uncoated in any way. This is because in some circumstances, perspiration, humidity, and close wear contact will cause the very best dyes in leather to bleed, staining a suit that may well cost more than the knife! Ventilation is important, as is comfort and accessibility, as well as a beautiful work of finish, gemstone, and treatment that results in a knife that is suited not only to the task, but to honor the dedication and level of commitment of the professional. If you understand this level of security, you will understand why I make these highly specialized knives for some of the best clients in the world. In the future, you'll see mention of my PSD knives more often on the site, as they are becoming more specialized and desired every day.

It's truly an honor to make this particular type of knife, and if you are a Principal Security Detail, Personal Security Detail, or other armed professional, you know just exactly the type of knife and rig you need.

I will go into the history of man and the knife and edged weapon's role in my book, but for now I can accept that you are reading this because you want to know more about counterterrorism knives and specifically, the counterterrorism knives I create in the studio. Some background is then necessary to understand this crucial knife, its role in the fight against terrorism, and how this specialized field is shaping modern weapons and warfare.

If you are squeamish about knives, you should browse to another site now. On this page, I won't sugar coat specific factors or descriptions, won't walk a politically correct line of flowery and generalized words, won't soften the imagery for the overly vulnerable. Conversely, I won't bloat my facts with mall ninja intrigue, false contrivances aimed at macho wannabes, or doomsday preppers convinced the zombie apocalypse is at hand. I also pledge to be non-graphic, write in a professional manner, and offer plenty of detail about this specialized knife.

What I will detail is the real thing, because that is what I make. I make them for the very best counterterrorism teams in the world, the very, very best. Welcome to the real world, where there is such a thing as a counterterrorism knife.

What is a counterterrorism knife? Perhaps it is easier first to define what it is not. It's not a camo-painted blade and a flashy cardboard box with the crosshairs of a sniper printed on the lid. It's not a CNC-created, mass-marketed knife that feels like a brick and is claimed to be designed and used by some secret special covert ops group no one's ever heard of. It's not a knife designed by a guy who was once in the military, but is now a knife designer selling his ideas to Chinese manufacturers. It is not a knife funded by an internet campaign, created in the bowels of a personal computer, and milled by a Computer Numerically Controlled (CNC) machining center. It is not a big, three-rivet handled, non-bolstered knife made of mysterious blade steel, and sold without a sheath. Frankly, there are very, very few knives made with the direct input of counterterrorism professionals, used by counterterrorism professionals, in real counterterrorism operations.

What I want you to know is how to compare. That's it. Know and understand the limitations and failings of what others are offering, and compare it to what I offer. It's simple, and it's very clear:

A real counterterrorism knife is a knife designed with the input of, built for, tested by, and used by the top counterterrorism units in the world for their daily professional use in handling, disarming, and eliminating terrorist threats. It is the real thing, and that is what I make.

Introducing my new "Shadow" line of knives, I've created the Shadow line because my counterterrorism clients have repeatedly requested completely subdued packages, knives and full accessory compliments that are dark, flat, minimized, and with minimal visual imprint. While these could be called stealthy, that wouldn't quite be accurate since these are highly effective, substantial, and imposing weapons and tools that are not easily hidden! It has taken a lot of research and experimentation to come up with the processes that define the Shadow line. I start with my effective and well-recognized combat and counterterrorism knife designs, and add as many features and accessories possible so that these ensembles will interface with all the gear, in every situation, as dictated by my combat and counterterrorism clients. They have given me the guidance to create this gear, and I believe it is the best of its field in the entire world. I know of no other knife maker or manufacturer that has even come close, and none that have even tried.

Creating a substantial CT (counterterrorism) knife is just the start, and even that is a continual evolution of process, conversation, field trials, and feedback from the guys who absolutely use these knives in the most serious action and scenarios one can imagine. I give special thanks to our United States Military; specifically USAF Pararescue, Army Infantry, Special Operations, Navy SEAL Teams, and Marines that have guided and influenced my work. Additionally, special counterterrorism recognition must go to the Israeli Defense Force/National Police Force YAMAM members for their input and advice in creating this evolving line. It is because of these men that I continue to strive to provide what they ask for and need. It is a huge honor.

The evolution of this line includes sophisticated designs, complicated and lengthy heat treating and cryogenic processing of highly evolved knife blade steels, careful attention to high strength blade-to-handle and hand-to-knife design for maximum application of force with high security in grip. The evolution includes unique serration geometries, puncture, piercing, and breaching features, and strengthened points and edges with the maximum geometry that balances strength and cutting ability. Continue this with unique and brutally tough sheaths, the very best in the world, with positively locking, or hybrid tension-locking, with variable retention and release options. Evolution of the metal components of my sheaths, mounting, and wear options are high strength materials, corrosion resistant materials, aluminum and titanium alloys which are anodized, hard surfaced with the wear resistance of ceramics. All included accessories, mounts, and designs have evolved, too.

The color and reflectivity of these packages is important. CT and military clients requested non-reflective, flat, dark hardware, mountings, fittings, and blades. They requested this as well as extremely high corrosion resistance, and the durability my knives, sheaths, and accessories are known for. This was particularly challenging, and I worked, experimented, built, tested, and refined my processes to bring the Shadow line of knives to being. Every ordinarily visible component on these packages is darkened, subdued, non-reflective and obscure. How have I done this?

My CT clients have been asking for this for years, and I'm excited to now be able to offer it, in my new Shadow line of tactical knives.

You are either gripping the handle, or facing the edge.

You might wonder why specialized CT knives are needed. After all, don't regular units, law enforcement, SPEC OPS, and military units already use knives? Why the focus now on this very specialized type of knife? This is a great question.

After lengthy discussion with professional counterterrorism operators, Principal Security Details, and other related and associated units, it's clear that there are two directions to modern warfare and defense. I want the people who read this, whether interested public or serious operator, to understand the view of the climate of weaponry, particularly weaponry from the most basic perspective.

Everybody has heard of tech. Drones, computer and GPS operated missiles, smart guns, smart targeting, smart surveillance, smart scanning and even smart flashlights are the rage. All this tech is absolutely necessary in modern warfare, in fact, it is essential to take whatever steps are necessary to prevent lives of our own, our allies, our countrymen, and our families from being lost to terrorists. We must use everything at our disposal to prevent and eliminate these threats. I appreciate this technology, and rely upon it.

There is, however, a special concern for basic, rudimentary defense strategies. When a terrorist goes on a rampage on a crowded bus with a knife, and none of the other people are carrying even the simplest of knives for defense, this is a very serious concern with deadly consequences. When a military soldier's closest thing to a knife is a folding multi-tool in his back pocket, he is, in essence, defenseless. In a lonely ally, when two policemen are jumped and attacked at very close contact, and don't have the time and distance to operate their firearms in defense, they can be left wounded and dying. When a female soldier wears the uniform in public and has not even rudimentary defense of man's simplest tool, she is prey to opportunistic kidnapping and terror. These are all real scenarios; not something I just made up.

Now, for an instant, imagine what would happen if there were an EMP (Electromagnetic Pulse) created by the detonation of a nuclear weapon high in the atmosphere, or even by a portable device (which are known to exist). All that tech, the smart phone, the smart communication, the smart vehicles, tools, weapons, targeting systems, tracking systems, and even LED flashlights (the mainstay of all modern portable and critical lighting) would be rendered absolutely useless. Inoperable. Dumb. Dead.

Okay, say you're willing to gamble that the EMP won't happen and you'll always have batteries, ammo, clean and dry tech, and sunny days and quiet nights. But then, someone attacks in an urban setting, from very close, so close that you don't have time to grab, chamber, aim, assess collateral, and fire. Don't even suppose that the first round misses a critical organ of your very own personal, dedicated, and insane terrorist, but then he, being very close, grabs your firearm. Now what? Where is your last line of defense? Where is your knife?

I'm not trying to be an alarmist, but in all of this, there is one thing that is abundantly clear. The knife is a weapon and tool that can not be rendered safe, can not be rendered useless, can not be ineffective to its purpose, unless it's locked in a sheath or left hanging on someone's wall at home or on base. It can't misfire, jam, or run out of ammunition. It isn't susceptible to dirt and sand, made inoperable by mud or water; It can't run out of batteries; it can't be rendered as useless plastic and metal if it's shorted out by an electromagnetic disturbance.

Knives are the most basic human form, created long before man (Homo sapiens sapiens), ever existed and we are all ultimately aware of their capability and function. Knives are surprisingly simple forms, though sophisticated knives like you see here are more effective and important for personal security. They are the last line of defense, after sanctions, information, prevention, missiles, mortars, and hand-operated firearms. They are the very last defensive tool available (apart from a finger in the eye), and as so, are absolutely critical to the structure of a well-defended soldier, cop, person, or society. Properly made and outfitted, they can be worn in all environments, they are simple to use, and they are available to anyone who has a hand. Good grief, terrorists have knives, yet most military professionals don't!

This is changing, and the wide ranging array of weapons must start (and end) with the most basic one, a dedicated, well-worn and easily and quickly accessible weapon with no moving parts, no possible way to render it ineffective, the ultimate close quarters defensive and offensive weapon that can find it's way around body armor, punch through seven layers of clothing, has sufficient length to pierce all critical internal organs, is sharp enough to slice open any part of the human body it comes in contact with.

You are either gripping the handle or facing the cutting edge and point. It's a simple, basic decision, and that is why counterterrorism knives are now coming of age. Why simply forget or even eliminate your very last line of defense? Most counterterrorism units know this, and that is why I make these specialized knives.

Hello Jay,

I have received the PJ-CT kit and I'm getting familiar with it.

As I told you before it's everything I always looked for in a knife and beyond, a true "universal" one. Size, balance, sharpness, handle shape: it fits me perfectly.

Life and Real World (versus Fantasy World) is full of uncertainty and danger. A bad move can end up really bad. That's why we need to think, learn, assess, plan, then act...

Whenever we have to rely not only on mind and body but on things and tools, there are some that simply can't fail, because just one failure could be too much. Be it a parachute,

scuba diving tank or assault rifle, it must do what it's meant to, when and where you need to.

A knife for the Real World is just that, not something looking good or "tactical" but a performing one. The problem is, of the countless knives actually made, the real ones

are few and far between. Again, we need to think, learn, assess, plan, then act...if you do, you clearly understand which ones you can rely on.

Handling a Jay Fisher's knife is like experiencing true love. When you do, you can't accept compromise anymore, or settle for less.

--R.

People ask if I make counterterrorism knives for the non-professional, that is, someone who is not directly involved in counterterrorism operations, law enforcement, military, or protection services. The answer is yes, but not frequently.

At the time of my writing of this topic, I'm fairly deep in orders and commissions. It's not easy to get a knife from me, as I do have a backlog of orders and commitments, and this is how it should be. Nevertheless, I am continually striving to make and offer every type of working, collector's, and chef's knives to the public. For each custom knife order I am making, I'm making at least one other knife that I will put up for sale on the website, on my "Knives for Sale" pages linked at the top border of every page of this website.

People ask why I do this; why not just work only on custom orders?

Just because counterterrorism knives (and kits) can be applied to CT uses, this doesn't preclude them from being applied to daily chores, work, or carry. Knives are, after all, blades and handles, cutting tools, and many of my CT clients use their knives daily. I have ranchers who wear and use the knives daily about their outdoor lives, hunters who choose the broad cross-application of these durable knives for their cutting and edge-holding ability, and people who just like to have the knives and kits available in case things turn sour and the need arises. They are, after all, the very best of this type of knife made.

How can I say that? Well, here's a task for the doubting reader of these words. Find someone, anyone, who can offer what I offer even in my basic CT knife and kit. You won't. You won't find any knifemaker willing to spend a week in complex and advanced deep cryogenic treatment of extremely high alloy tool steels. You won't find any other knifemaker or company that even comes close to the geometry, fittings, arrangement, styles, balance, accessories, and service I offer.

Why? Because I listen to my clients, work with them, and complete and offer knives and kits based on their professional input and my experience. It's a great relationship, as old as mankind, and I'm honored to do my part. In sharing this tradecraft, science, and art with others, I appreciate that any person who has an interest in this type of knife and kit should have access to it, even if it's just to hold in their hand and understand. After all, we live in a free country.

And if the owner needs his counterterrorism knife one day, he will have it, perhaps passing it down to his grandchildren.

Jay,

I was dumbfounded when I held my counterterrorism knife and tension-lock sheath, as in ‘found dumb.’

Both the knife and sheath felt foreign in scale, weight and utility. I realized I’d never held a defensive

blade capable of defending my life, and had had a false sense of security with the automatic dagger I’d been

carrying in my pocket, and my fixed blade hunting knife I own. It was like the difference between holding

a baseball bat and a broom handle, for self defense. I’ve never fended off an attack, but I realized yesterday

that if I’d had to, the weapon I purchased from you was an entirely superior tool, and my confidence in the

other knives was completely unfounded. My grip on your knife was the first thing that struck me as so vastly

superior. I was ignorant before yesterday of what type of tool I’d want and need in an actual fight. My

grip on the Torvus alone made me realize what a fight-worthy handle is, and how underprepared I would have

been before. It was a humbling experience. I felt I’d been dumb before — I had expected to feel excited,

and was actually dumbfounded instead. And examining the blade, feeling the weight, I realized that this

blade would penetrate jackets, belts, and that the blades I had relied on before would only work if my

attacker was in shirtsleeves only. I also thought that if I were to face another man with an authentic

weapon like yours, I’d want nothing less than a pistol to fend him off.

What a humbling experience. There’s something almost ancient-feeling about your blade. Like a weapon from before firearms when armies depended on hand to hand combat and manual weapons. I own a genuine samurai sword, and the density and balance of that weapon is the closest comparison I’ve experienced, but I certainly didn’t expect to hold a 6” blade with the sense of heft and lethal purposefulness of that sword. I’m dumb founded, and even relieved that I discovered the difference.

Thank you,

D.

A real counterterrorism knife is a knife designed with the input of, built for, tested by, and used by the top counterterrorism units in the world for their daily professional use in handling, disarming, and eliminating terrorist threats.

It is not in my realm or desire to go into security surveillance, data analysis, movement tracking, and radicalization. I don't work in targeting operations, deployment, and mission parameters and operation. I only work in one thing and one thing only: knives. In this realm, I have a close affiliation with the very people who need specialized knives; they contact me, inform me, guide me, and support me in my effort to bring them the very best possible knives to suit their needs. These designs and many of other types of knife design on my website and record are made with direct input of the professional, whether he is a chef, a hunter, a collector, a soldier, or a counterterrorism professional.

From my perspective, counterterrorism tools must be superior to all other combat knives with specialized features. The professionals I work with tell me that the reason they come to me is because they cannot find what they need elsewhere. They tell me that other offerings are "bricks," the companies and individuals "drop the ball," and they won't even take their knives into the field because they just don't perform. The offerings of many manufacturers, boutique shops, and other makers are lacking in many critical features necessary to counterterrorism performance.

What are the features? They are detailed in the topics below. The language is clear, the facts are plain; I'll simply describe how these knives should be. I'll describe how the knives I make are superior to all other knives in many ways.

It's not hard to know what a counterterrorism professional wants; just ask him and he'll be glad to let you know the failings, limitations, and necessities of his gear. As a professional myself, I believe it's my duty to provide him with the very best possible gear in the world today.

It's important to note that full-on counterterrorism knives are not cheap. It takes incredible labor and determination working with some of the most durable, tough, refractory materials available to create workable, useful systems for customized needs, and every single part of every single knife is meticulously handmade. If you are looking for a cheap knife for casual use, this is not the kind of gear I make. I am only interested in making the very, very best.

If you expect your enemy to be wowed (or stopped) by the click of a three inch knife blade, you need to get out more and understand just how dangerous the world really is.

A folding knife should never, ever be used for combat. Are you surprised to hear this? You shouldn't be. I've clearly outlined why on my Combat, Tactical, Military, and Law Enforcement Knives page at this bookmark. The facts are simple and clear, and detail the distinctive difference between a knife that folds up and is pushed in a pocket, clipped on the belt or gear, and one that is dedicated to saving your life. Just for illustration, here is an email response I gave to an inquiry about using a folding knife for counterterrorism or life defense in a combat situation.

It's not something the companies who make this kind of knife want you to consider; they want to sell the flash and gimmick of knives flipping and clicking and people cowering away at the sight of the sudden appearance of a little pointed blade. It's important to consider that the enemy can be smiling in your face one instant, and in the next wildly slashing, stabbing, and cutting you as fast and as furiously as he possibly can, while on top of you as you try to get away. This is a horrifying scenario, and it's happening daily as I'm writing this.

In movies, television, and video, there is always time: time for the hero to assume a stance, time to grab his weapon, time to move the weapon into position, time before the enemy attacks. If there is more than one enemy, the others dutifully wait their turn so the hero can dispatch them one at a time, at a convenient pace.

This is total Hollywood crap, and bears NO resemblance to the reality of combat.

If you are one of those people who expect your enemy to be wowed (or stopped) by the click of a three inch knife blade, you need to get out more and understand just how dangerous the world really is.

The inquiry was first about a company that sells manufactured automatic (spring operated and spring opening) knives, and their own knives. In my response, I detail why this is a bad idea. Remember, this is not while playing with a folding knife in a peaceful, clean, calm, and leisurely fashion, which is always how these knives are demonstrated, displayed, and sold. This is not about a choreographed dance of display created for the silver screen. This is about a real life dirty, clumsy, and sudden reckless situation, where someone is on top of you with a knife or other weapon, wildly attacking, putting their life's force into an assault meant to kill you and permanently remove your soul from your body. Think very seriously about this; it's not a game.

My response:

To answer your question (about automatic folding knives in combat), there are some serious considerations here.

First, about the company. The company is a gunsmithing company started by a family and they contract out blades from P**-T***. P**-T*** is run by (name omitted), and it’s only been around since 1999. They claim that the knives are made in America, but this is not specifically true. They are assembled in California, made from parts contracted out from foreign companies. They pride themselves on having no hands on the knives, and the parts that will become the knives are made by CNC machines and EDM machines, and laser cutters, and by computer automation. They make only some parts in CA, slap them together in CA, and then claim they are made in America, which is, in my book, disingenuous, if not an outright lie. With foreign companies, you don’t really know what you are getting in steel, treatment, or durability. P**-T*** takes designs submitted by makers, pays the makers for using their name, and their notoriety, but the knives are somewhat questionable. Why do I say this? In the ads, they give the steel type (none are powder metal advanced technology tool steels), but they don’t even tell you the hardness. Rather important, I think. The blades are coated with a hard, thin coating that has no purpose other than to make them black, and avoid finishing the blade. The edges of course, benefit from no coating, where it could actually contribute to the knife performance. Another issue is the handles. They are made of 6061 aluminum, not a particularly hard, corrosion resistant, or high strength aluminum alloy. Most are squarish and uncomfortable, because they are made on a CNC mill. But then there is the price point, and now you know why. But for the money, it’s a fair value, I suppose. This is not the issue, what follows IS:

The folding knife relies upon a tiny piece of metal to secure the handle to the blade, and it’s generally about ¼ of an inch in diameter and often smaller. It's called the pivot. Then, there is the lock which is much, much smaller, perhaps 1/8" or less. In automatic knives, the huge looming problem is that they must be sloppy so that the spring can push them out of the handle. So there is a lot of play in the mechanism, because if it was tight, it would resist the rotation of pivoting. So this weakens the construction. Another factor is the lock. Most of these locking autos have a tiny little piece of metal that does the locking, and that is supposed to hold it all rigid. These autos do not have a liner lock, which is a much stronger lock mechanism, and would not work on an auto. Another consideration is the release. This may be a button or small bar, and when you press it, the blade is pushed out with a spring. Often, in the design, the same button is used to unlock the knife so it can be folded. Here is the problem. If that button or lever is pushed while you are gripping the knife, it will fold… on your fingers. There simply is no way to prevent this! Touch the wrong part of the knife during combat, and it folds like a paper cup, and always on your fingers, but maybe into your gut.

From a combat standpoint, I know what I would trust, and it makes sense to logically compare the folding knife with the fixed blade. Let’s say someone is attacking you, intent on killing you, with their hands, knife, or implement. If you can’t get away:

From this, you can see that there are some serious issues. But companies don’t care about this, they think you will think it’s hip, slick, and cool to see a blade click open and you are in "West Side Story," or "The Cross and the Switchblade," or "Chinatown," and you are street-cool and a mean dude. When mall ninjas use their auto knives, they wear them out by clicking and clicking and clicking, and they use them to cut open boxes, and a loose thread, or a piece of tape.

Man to man, if I had to use a knife and someone is on me, I want to reach to my core (by folding my arms in a defensive position across my chest) and have my hand on a fixed blade immediately when I do this. This means that the optimum position for the knife sheath mount is at my sternum to left shoulder. I don’t want to unlock anything, position anything, just grab, and a stout double edged piece of strong, hard, durable, super keen-edged steel is locked in my fist. The bigger the better is nice. I don’t want to have to assume a practiced stance, I just want to move the blade toward my enemy as fast as I can, punch away as hard as I can, and inflict lethal damage.

Sounds like the Guardian and Vindicator, right?

Problem: Manufacturers, boutique shops, and most other knifemakers do not make custom or made-to-order knives. They simply offer what they have, occasionally with options. They have determined what they want to sell as a combat knife, and the counterterrorism professional is simply left with the choice of the manufacturer. While this may be adequate, many times it is not, and this is when the custom knife conversation is necessary, but impossible. Manufacturers, knife making boutique shops, and most other knifemakers do not accept custom orders; they won't build a knife to your specifications.

How to tell? Ask them if they will build a knife to fit your individual hand size. If the answer is no, find another source.

Solution: The best counterterrorism knives are custom made, by hand. The client contacts the maker with specific features, size, shape, and performance in mind, and it is my job to create the best possible knife I can that will fit within his parameters and budget. This means an individual and unique design, premium materials, and proper treatment, processing, and verification of the build. This means fitting the knife to his hand, fitting the wear option to his gear, this means additional accessories made to the highest standards. It starts with a conversation.

The conversation is as old as man; a warrior and a craftsman discussing ideas, needs, and requirements. The craftsman tells the warrior what is possible in the realm of his technical experience, the warrior lets the craftsman know what he needs in his critical job. The tool is made, carried, and evaluated, and oftentimes reviewed and improved based on those evaluations. This is how superior tools of every kind are created and evolve. It's all about the individual conversation. Without the conversation, the warrior is simply a consumer, without choice, without input, without individualized care, details, application, or service.

Problem: Many knives touted as counterterrorism knives are simply combat knives, and most don't even rate that classification. They are typically sold with an advertising phrase, in a different venue than other stock, or by directed marketing. While there are many similarities between combat knives and counterterrorism knives, there can be critical differences that may be neglected in materials, finish, shape, features, treatment, and accessories.

How to tell? Does the knife have a penetrating point instead of a survival or chopping point? Does the handle have improved grip features like finger rings and radical quillons with plenty of curve? Does the gear accommodate many different wear options and sets? Is all of the rig made to the very highest standards of durability, corrosion resistance, serviceability, and use possible? If any of these answers are no, find another source.

Solution: With custom knifemaking work, all factors critical to individual counterterrorism needs can be considered, and this includes specific features like heavy, thick points that are created at aggressive angles for penetration, radical grinds that allow razor edges with full heavy spine support, worthwhile and aggressive serrations that can cut metals and tough textiles, improved grip features to assure the knife stays in the hand, and non-lethal features like talons, persuaders, and even carbide glass breakers. The sheaths may be quick removal types, with retention, the accessories dedicated to nighttime or subdued operations. Counterterrorism knives may have a wide variety of mounting and wear options, to interface with a wide variety of specialized gear. The CT knife is an assembly of many components, a kit of gear suited to quick adjustment, change, and fitting for each mission and gear set, made in the most modern and advanced materials and construction.

Problem: Most factory, manufactured, and boutique shop knives have inferior blades. Their blades are either too thick for penetration, too thick to sharpen and maintain, and made of steels that represent economy for the manufacturer, not superior performance for the user. They may claim their steel is of a special designation, and a "secret" alloy. They often do not have substantial spines for strength, and are never accurately ground. They typically flat grind blades and the grind terminations are squared off creating a weak blade that can break at the blade-to-handle junction. They often use CNC machines to create the blades, and that process alone produces a blade that is too thick and blocky. The blades may not even be tested for proper heat treating and tempering, and are always very basic in their construction. A lot of plain carbon steel is used, or 420 series stainless steels that can't be hardened any more than 52C Rockwell, dozens of times softer than tool steels. You'll also see steels like CPM3V, which is shock resistant, but is not wear resistant. Some are even hand-forged, and that makes them inferior to all high alloy blades by several orders of magnitude in strength, wear resistance, corrosion resistance and dependability.

How to tell: does the blade have a deep grind with substantial spine? Are the grinds accurate, with rounded grind terminations? Is the knife blade made by hand? Is the steel a known and identified steel classified by AISI, ASTM, SAE, or in steel references? Do they give exact hardness of the steel or just a range of hardness? Is the steel a high alloy tool steel? Can you choose the steel alloy to make the blade from, and can they clearly offer distinctions and advantages to the steel choice in plain talk? If any of the answers are no, find another source.

Solution: The superior counterterrorism knife blade is accurately ground, by hand, as only the hand can properly gauge and create a knife that has radical and variable geometry along its length, accommodating thinner and thicker areas, recurve areas, and specific features like serrations. The thin blade edge geometry can not be created by a CNC (computer numerically controlled) machine, only by hand. The steels for counterterrorism knives are the very best modern tool and die steels made, made with modern processing and treatment and never, ever hand-forged (heated in an open furnace and shaped with a trip hammer or hand-hammer). Only weak and inferior steels can be hand-forged; there is no such thing as a forge in a modern industrial machine shop where the finest tools are created. There are no "mystery steels" for the professional; your firearm is made of known and identified metals, so is your armor, so is your armament, and every piece of military hardware has to be specified (Mil Spec) so the materials are known and the results can be predicted. It's ridiculous for a company to offer so-called mystery steel, and expect a professional to trust it while not even knowing what the alloy is! In blade geometry for the counterterrorism knife, spine strength is paramount, and thinness at the cutting edge critical. The edge must be properly ground to be sharpenable during the lifetime of the blade, the only field service provided by the knife user. A very careful application of geometry is used in my counterterrorism knives, one that allows maximum thickness and strength at the point with high sharpness. The point of a CT knife is a very important area; it needs to be as stout as possible with additional reinforcement often built into the geometry of the design. I offer a wide variety of serrations that can rip through many materials, even some metals, and full tang construction provides maximum handle-to blade strength. The serrations are individually created by hand for each particular request, and are the most aggressive made on any knife. Complex grinds with a variety of wheel sizes are necessary and are completed to exacting standards and geometry. Ricasso areas are kept small for maximum blade edge exposure and length. I use the highest alloy homogenous and isotropic tool steels made, each and every one properly hardened and tempered and tested on a calibrated apparatus. The blades are tested in the field, in real world situations, and then improved by the direct input of the CT professional, until he is absolutely satisfied with the performance. The finishes are flat and non-reflective, but never coated which would hide any flaws or irregularities in the blade.

Problems: Sometimes, the lighter frame, narrow profile, and smaller footprint are necessary in counter terrorism operations. The operator, agent, or unit professional needs the cutting ability of the edge, the piercing ability of the point, and perhaps other features available for this specialized knife and tool. Another requirement of the skeletonized knife is its ability to be completely cleaned, sterilized, and used in operations (such as diving) where corrosion concerns are critical and all areas of the knife need to be accessed for cleaning. While the blades may be similar to the full-handled and bolstered models, the handles are the main issue, followed by the sheath. The offerings by manufacturers, boutique shops, pre-production shops, small production shops, and most knifemakers are lacking in these specific ways:

How to tell: Does the profile look blocky? Is it straight, with no curves to help hold the hand grip? Does the handle look squared off at the corners? Are there abrasive-looking jimping cuts anywhere the hand has contact? Does the webbing between and around the skeletonized parts of the knife look thin or weak, or thick and overbuilt? Does the sheath look thin, narrow and weak? If any of these answers are yes, find another source.

Solution: In my skeletonized knives, the build does not depend on the stock width, but in the operator's or user's needs. The steels are tough and corrosion resistant, they are ergonomically formed with substantial curves, swells, and shapes that aid in grip strength and security. There are often finger rings, oversized for gloves or fitted to the individual person's hand by custom build. All corners, edges and surfaces are rounded, smoothed, contoured and clean, to prevent abrasion or injury to the user. The webbing and structural support of the handle is sound, while as much weight as possible is reduced. I include features such as talons, persuaders, crushers, and glass breakers. The sheaths I provide are as well built as all of my tactical combat and counterterrorism gear, and interface with the same huge amount of accessories, so the knife can be fitted out to the mission variables. More about my skeletonized knives at this page.

Problems: Most manufacturers and most knifemakers provide either weak or non-existent fittings. This is a huge problem, one that is seen over and over in our industry. It costs time, materials, labor, and skill to properly fit a knife for maximum strength, and making knives as cheaply as possible leads to a continual repeat of the same type of handle over and again: a slab of CNC-cut Micarta or G10, secured with three rivets and no bolsters. Variations are two rivets and a hollow tube for a lanyard hole, or even just two big pins or screws. This is a terribly weak way to mount any knife handle, and it is the mainstay of our industry. Makers and manufacturers simply refuse to bolster their knives, because it's too much work and takes too much skill. Rarely, when makers do use stainless steel fittings, they use 410 stainless which is not highly corrosion resistant, and does not even become marginally corrosion resistant until it is heat treated, which is never, ever done! When bolsters are used, few makers ever round, contour, shape, radius, and smooth the edges and transitions of the bolster so that it is comfortable to the human hand, gloved or not. This is one of the most neglected parts of bolster design and execution, and a reason most makers and manufacturers would rather round and finish softer material like the handle material, and forego bolsters altogether. When other makers mount bolsters, they neglect dovetail of the handle scale area, and finish this at 90 degrees, which is a weak way to mount any bolster. It does not matter whether the bolster to handle scale junction is straight, rounded or curved; what is important is that the dovetail of the bolster overlays and locks the handle scale to the tang, so that the handle will not come off, ever, when huge forces are applied.

How to tell: Are there any bolsters? Are there multiple pin arrangements and bedded handle material locked under the bolsters and secured to the full tang? Are the bolsters and fittings made of the highest corrosion resistant materials available? Are the bolsters dovetailed at all? Are the bolsters radiused, contoured, rounded or smoothed for grip? If any of the answers are no, find another source.

Solution: All heavy use knives counterterrorism knives should be fully bolstered, front and back, at the ricasso and the butt, and mine are. I bolster with the best materials possible, usually 1/4" to 3/8" thick zero-care 304 high nickel, high chromium austenitic stainless steel, secured with multiple zero-clearance expanded pins, 1/8" or larger. Some of my specialized knives even feature T2 Titanium bolsters, a full .250" thick. The bolsters will not come off, loosen, or move, ever, and they won't corrode, ever. They give a wide, heavy, thick location to apply force, they strengthen the blade-to-handle junction, they reinforce the butt of the handle, the lanyard attachment, and talon or persuader location. They balance the blade weight, and they lock the handle scales to the tang mechanically and physically by dovetail construction, and the handles can not come off, ever.My multiple handle pins work with the bolster geometry and full permanent bedding to secure the handle scales to the tang with unsurpassed strength. The bolsters are completely radiused, contoured, rounded, smoothed, and finished for a comfortable and stable grip without any chafing, injury, or abrasion. The bolsters feature points, like thumb rises and finger grooves are wide and comfortable, and interact with sheath retention methods to secure the knives without concern. Even lanyard holes are large and smoothed inside and out, chamfered and smoothed to eliminate abrasion of the lanyard and ease donning and doffing various lanyard types.

Problem: Most factory knives, and most knifemakers make knives that have straight, and uncomfortable handles with poor geometry. Oftentimes, the tangs are not tapered, leading to a heavy handle balance and extra weight where it does no good. This is done because a straight, narrow piece of marginally worked steel is much cheaper than a wider stock with substantial machining, and it's all about economy for them. The handles are often narrow, squared off, with some roughing of the handle scales by CNC or hand file in an attempt to improve grip security. This only makes a rough, uncomfortable handle and an uncertain grip. Squared-off areas will cause pain and discomfort to the hands, even if gloved, possibly injuring the knife owner during the most critical moments. The worst offense is a hidden tang, which is simply too weak for combat.

How to tell: Does the handle have deep curves, large quillons, and noticeable belly to fill the palm and fit the hand, and will the shape lock the handle into the hand, preventing the fingers from sliding forward onto the blade? Are all surfaces including the bolster and quillon areas rounded, smoothed, contoured, and dressed for the comfort of the fingers? Are there grip improvement features like finger rings and are they rounded, dressed, contoured, and smoothed? If any of the answers are no, find another source.

Solution: In my counterterrorism knives, I create the most secure handles possible, using whatever stock thickness required, always full tang construction for ultimate strength and one piece of steel from tip to butt. I often incorporate full finger rings, forward or reverse, that are rounded, contoured, and finished for a smooth and comfortable grip. Often, the handles are sculpted and shaped for the individual owner's hand size, custom fitted to the individual, and even made to accommodate gloved wear if needed. Some knives are made with handles that are specifically designed for specialized grip styles, like reverse grip, edge out. The tangs are always tapered and milled for correct balance while maintaining strength. All materials are extremely well-fitted and finished and are always bedded permanently and chemically to the tang. I don't create rough, jagged, or bumpy texture to improve grip security, I rely upon the handle shape for security. More about tactical knife handles here.

Problem: Most sheaths made in the modern world of

knifemaking are weak, flimsy, and short-lived. This is the most

shocking factor in our trade that I've seen since I made my first knife

in the late 1970s. The sheath is the most important part of any

actual combat or counterterrorism knife; it is how the knife arrives at

the mission. Sadly, typical of the combat knife is a single layer of thin

(.060", 1.5mm) kydex, hot formed over the blade and handle, held

together with soft brass rivets, eyelets, or grommets. There are no

welts to strengthen or frame the sheath, only thin kydex. This is a

terrible way to make a sheath and this is the industry standard, and you

see it all the time. It's not a strong sheath, it will crack and fail,

sooner or later, and it's not safe. This is a sheath that

continually wears down, and is not serviceable in any way. Remember, a

well-designed and well-constructed sheath is the only way

a knife can be made safe, and only then if it is retained or locked in

the sheath! No one seems to make viable retention methods other than

tension, and tension on a single thickness kydex wall is tenuous at

best. The sheaths can not be trusted, they are not safe, and seldom

interface with viable combat gear. There is no variation or

accommodation to gear, and belt loops are typically folded plastic or

plastic clips added on as an aftermarket item. Oftentimes, the wearer of the sheath is supposed to

use ties, typically Paracord (550 cord) to tie this sheath to his gear.

There is nothing more clumsy, untrustworthy, or unsafe as Paracord on

any knife; it can hang, flop around, tangle in obstacles, and restrict

movement or escape. I write about it as a useless handle

on this link on my Combat/Tactical Knife page, and it's just as

dangerous on a sheath. Remember, a knife is worn into battle, not carried. The

sheath then, becomes the most important part of the assembly of any

combat or counterterrorism knife!

How to tell: does the sheath look like thin

kydex hot-formed over the blade and part of the handle? Is the kydex

bent in half (folded)? Is the sheath covered with nylon with little

pockets and snaps? Are their ties, ropes, or cord attached? Are there

little eyelets or rivets around the outside edge of the sheath holding

it together? Does the company selling the knife expect you

to go somewhere else to buy a sheath? If the answer to any of these questions is yes, find

another source; they don't care about your needs.

Solution: In my combat and counterterrorism knives, I use double thickness (.125", 3.2mm) kydex bolted over a frame of 5052 H32 high strength, corrosion resistant aluminum alloy welts. The bolts are .250" (6.4mm) 304 austenitic stainless steel Chicago screws, and will not fail, ever. The sheath will not flex, bend, or break. The kydex is not a wear area, and all blade contact areas are coated with a bedding sealant so the edge contacts no metal. They are entirely waterproof. My counterterrorism sheaths positively retain the knife. In my positively locking sheaths, I use a multi-component all stainless steel locking assembly that locks the knife into the sheath in any position and will support the weight of a man. I also offer an option of a hybrid tension-locking system that retains the knife in any position, requiring 15-20 pounds of force or manual releasing to unsheathe the knife, using titanium and stainless steel and a variety of retention springs for varying release preference. The sheaths come with an assortment of belt loops, footman's loops, retaining straps, horizontal mount plates: all made of high strength, corrosion resistant aluminum alloy. I offer custom anodizing for the aluminum, in any color requested, that imparts a near-ceramic hard coating on the aluminum that is twice the thickness of the industry standard. The loops and hardware are an integrated part of the sheath system, and can be mounted in multiple positions and sides and all sheaths are reversible. I offer an array of loop, strap, and clamp sizes to accommodate a wide variety of tactical belts, and they are all interchangeable and reversible. My sheaths are simply the finest combat and counterterrorism knife sheaths made in the world today; none can compare. More about these incredible sheaths here.

Problem: Manufacturers, boutique shops,

pre-production shops, small shops, knife companies, and knife makers do

not offer any accessories of any kind! At the time of this writing, none

of them offer any useful adjuncts, helpful accessories, or equipment and

fittings to vary the mounting, wearing, and use of any of their knives!

Want a wider, thicker belt loop accessory? Nope.

Want a set of plates that allow the knife to be worn horizontally behind

your back? Nope. Want to wear the knife,

handle down, across your sternum so it won't interfere with your other

gear? Nope. Want to wear your knife

horizontally behind your back but not have to worry about retention or

dyes bleeding onto your clothes? Nope. Want flat clamping straps

allowing the sheath to be secured to any Pouch Attachment Ladder System

or body armor straps? Nope. Want to carry a sharpener to touch

up your edge? Nope. Want to have a powerful,

modern, programmable flashlight that you can aim in any direction

mounted on your knife sheath that frees your hands? Nope.

Want a small, light, and unobtrusive flashlight that can back you up

when other lights fail or run out of battery? Nope.

How about complete anodizing of aluminum and blackening and oxide color

of stainless steel so all the components are glare-free and matching?

Nope.

Want to have all the accessories removable, reversible, and modular so

you can choose how to set up your gear for individual mission

parameters? Nope.

How about a belt loop extender (common on firearms) that lowers the

knife position off your hip, where real estate is scarce in your tactical

load? Nope. How about plenty of stainless steel

hardware, mounting assemblies, and storage units to stow your gear?

Nope. How about a positional lamp that has IR

safe night vision safe, red, blue, and white light dimmable options in a waterproof

housing? How about a totally modular system for large tactical

knives that offers rig changes between sternum wear, belt loop extender

wear, and spine wear of a locking sheath that only takes moments to set

up and change? Nope, nope, and nope.

How to tell: do they offer any accessories at

all? If not, find another source; they don't care about your needs.

Solution: It's sad, but true. The companies

and makers referred to in this topic frankly don't care. How do I know

this? Because I work with real combat, counterterrorism, law

enforcement, and professional teams, and they all want and need critical

accessories to aid in their specific missions. They request these items

all the time, and since I'm not the only one making knives of this type,

I know they are requesting this from others. I can only assume that the

others don't care about their needs, and are negligent in their

services.

Here, I offer every item detailed above, and more, continually

developing, refining, and improving these unique tactical accessories.

These aren't just for show, the knives with accessories you see on this

page are in the field, daily, performing the tasks asked of them by

their owners, and they are extremely happy with them. I constantly

strive to improve my gear, improve the mounting and wear arrangements

and possibilities, the materials and options. Since the setup for each

knife and accessory varies between missions, my gear is then a system

of interactive devices, all interchangeable, efficient, and extremely

strong and durable. They are actually sheath accessories, since

they mount on and mount to the knife sheath. On the individual knife

pages linked on this page, you can read the details of my system, and

glean more details on the "Tactical

Combat Knife Sheath Accessories" page.

I make tactical, working, rescue, combat, and counterterrorism knives. Since they are real tactical knives, not just "tactical" in appearance, they are actually made to be worn and used in the most serious of uses. Because of their real world application, it has been necessary over the years to include everything my clients request for them. This starts with the toughest, most durable, and best made knife sheath in the world today (and ever): either my positively locking sheath or my hybrid tension-locking sheath. My experience has been that since the sheaths have to be worn, and since everyone is different and every mission or application is different, it's important to include all of the necessary straps, clamps, hardware, mounts, and equipment to wear each knife and sheath with every tactical knife.

It is rare that a tactical knife is only worn in one place; as the owner's gear is refined and regularly upgraded, the sheath must be able to mount to an evolving combat framework. Typically, a client who wears these knives will have multiple applications and missions, and because of the limitations of his other gear, he'll have to move the knife and sheath to different locations to accommodate. For instance, the United States Marine in desert warfare currently has only about one place he can mount a tactical knife, and that is along his leg, below the waist, and above the knee. Of course, this may change depending on his particular gear, environment, or mission. I want my clients to have all their bases covered, and every option available.

From time to time, I receive requests for tactical knives that are "bare bones," that is just the knife and sheath, and no accessories. I rarely do this because of the reasons above, but taking it a step further, let's just examine what would happen if I did offer simple knife and sheath combinations, without all of the other hardware.

I've had the experience of doing this very thing; this is how I used to make and sell my tactical knives. When I did, the first thing that would happen would be the client contacting me and saying, "Gee, I really like the knife and sheath, but do you have a way to mount it lower on the belt?"

This is how and why I developed and include the BLX, UBLX, and EXBLX Belt Loop Extenders.

Then a client would ask, "Is there any way I can mount this horizontally along my belt line?"

From this, I developed the Horizontal Belt Loop Plates.

Then a client would ask, "Is there a way I can fix the sheath to my PALS on MOLLE, or vest webbing?"

I developed the Horizontal and Vertical Clamping Straps.

Another client would ask, "Can you make something to mount the knife over my sternum? It's the only place I can wear the knife. And by the way, it has to be handle-down."

I created the Sternum Harness and the Sternum Harness Plus.

A client submitted, "I do a lot of work where I might be in the field after dark, and sometimes, even in the daytime, I need a small light for examination or emergencies, or just finding my way."

I created the LIMA, with the Maglite® Solitaire, then the Solitaire LED, and then the ThruNite® Ti3 LIMA.

Then clients asked, "The little light is great, but can you actually give us a main (or key) flashlight. We need one that can be our main lamp, with super-bright illumination for nighttime operations. Oh, and we need it to be able to be aimed in a fixed position, in any direction from the sheath. Then, we need to be able to remove it, replace it, and depend on the holder to never rust, corrode, or bend."

I created the HULA with Maglite® XL100, then XL200, then MagTac®, and then Fenix® E35 and Fenix® RC11, and Streamlight® Sidewinders. My counterterrorism clients claim that "Two lights are only one light, and one light is no light." This is a logical, serious, and practical observation, since lamps can fail, batteries can die, and components in flashlights, no matter how tough, can stop working. A simple failure of a light can leave the owner crippled in the darkness, so most CT kits have both the LIMA and the HULA.

Some of the accessories were needs that I noticed, like the simple need for a touch-up sharpener, so the pocket on the UBLX was added with a DMT Dia-Fold® sharpener. Another was the fire starter for outdoorsmen, less often requested. I had knives with lanyard holes, but no lanyards; two types were added. Lately, I've added real diamond sharpening pads with essential pad-bags to carry, store, and use them. When I noticed that some of the drawstring bags the knife kits were stored in were literally worn out, I looked for a durable duffle that could accommodate the entire kit. There were no duffles of any strength or durability, so I saw the necessity to create my own, with 1000 denier polyester coated, water resistant Cordura® ballistic nylon and heavy straps and zippers.

Consequently, the kits grew, and continue to grow to this day. My logic is this: I simply want my client to have everything associated with his knife. It's part of my service commitment to my career field.

Let's just look at what happens if I don't include all these accessories in the kit. I can reveal this because it's happened before. The client buys just the knife and sheath. He then notices that the sheath is a fixed form, and has a definite and universal mounting hole arrangement for straps and hardware. Since no one else in the world makes this, he then contacts me because he wants a different mounting or wearing arrangement. It's just a few straps to create, and maybe I can match the color of the anodizing with the rest of his gear, but maybe not, since I anodize in batches. But in order to make his accessories, I would have to stop what I'm doing (while years in backorders) to make the parts. More logically, he should take his place in the queue, and wait five years for his straps to mount his knife. What? And then later, he wants a UBLX, but it's custom made for the knife (they all are) and I have to have the knife shipped back to me, so I can get the sizing and arrangement correct for the custom fit, and maybe he has to wait five years for that...

You can see why this is impractical.

Another point is that sometimes, a potential client may think that if Jay just offers the simple knife and sheath combination, he'll get a big discount and get the knife for less money. And then, he can add those accessories as time goes on, to spread out his investment.

If a client is strapped to pay for the kit, he probably should not be buying the knife and kit. Most other makers won't say this, but the last thing I want to do is to impose any financial burden on my clients. I know what it is to live and work within a budget, and I also know what a tremendous amount of work it takes to make these knives; they are quite literally the finest, most complete tactical knife kits in the world. If you don't think so, I challenge you to find any that compare, anywhere. The fact that they are so difficult to make is why you don't see them anywhere else. This means that the incredible amount of labor means a higher price. As I've stated before, I'm not interested in making budget knives; I've only got one life and one career, and I want to make the very best knives (and kits) I can possibly create in that time.

Now you know about my counterterrorism knives, sheaths, and accessories. Please check back, as new models, components, and designs are continually added.

It would be great to live in a world where evil, misguided, and insane terrorists were not a threat, and we all pray for that day. Until then, the defense of our families, our countries, and our very way of life is a critical and essential reality, faced daily. I offer my deepest thanks to those who defend us, our allies, and our friends. I'm honored to be of service in this most important conflict of our time.

If you are a professional on the front lines, and need a service that I can offer, contact me. You know what you may need, and I will do my best to make sure you have the best modern tools possible for your requirements. And you'll be in good company!

Thank you for your service.

All of these knives are in service in the counterterrorism

field: in the hands

of military counter terrorism teams, intelligence officers, and police

special units. Some are in the hands of investors, advisers, and

training and support

groups.

They are made with direct input of these professionals.

Counterterrorism Knives Page Topics

| Main | Purchase | Tactical | Specific Types | Technical | More |

| Home Page | Where's My Knife, Jay? | Current Tactical Knives for Sale | The Awe of the Blade | Knife Patterns | My Photography |

| Website Overview | Current Knives for Sale | Tactical, Combat Knife Portal | Museum Pieces | Knife Pattern Alphabetic List | Photographic Services |

| My Mission | Current Tactical Knives for Sale | All Tactical, Combat Knives | Investment, Collector's Knives | Copyright and Knives | Photographic Images |

| The Finest Knives and You | Current Chef's Knives for Sale | Counterterrorism Knives | Daggers | Knife Anatomy | |

| Featured Knives: Page One | Pre-Order Knives in Progress | Professional, Military Commemoratives | Swords | Custom Knives | |

| Featured Knives: Page Two | USAF Pararescue Knives | Folding Knives | Modern Knifemaking Technology | My Writing | |

| Featured Knives: Page Three | My Knife Prices | USAF Pararescue "PJ- Light" | Chef's Knives | Factory vs. Handmade Knives | First Novel |

| Featured Knives: Older/Early | How To Order | 27th Air Force Special Operations | Food Safety, Kitchen, Chef's Knives | Six Distinctions of Fine Knives | Second Novel |

| Email Jay Fisher | Purchase Finished Knives | Khukris: Combat, Survival, Art | Hunting Knives | Knife Styles | Knife Book |

| Contact, Locate Jay Fisher | Order Custom Knives | Serrations | Working Knives | Jay's Internet Stats | |

| FAQs | Knife Sales Policy | Grip Styles, Hand Sizing | Khukris | The 3000th Term | Videos |

| Current, Recent Works, Events | Bank Transfers | Concealed Carry and Knives | Skeletonized Knives | Best Knife Information and Learning About Knives | |

| Client's News and Info | Custom Knife Design Fee | Military Knife Care | Serrations | Cities of the Knife | Links |

| Who Is Jay Fisher? | Delivery Times | The Best Combat Locking Sheath | Knife Sheaths | Knife Maker's Marks | |

| Testimonials, Letters and Emails | My Shipping Method | Knife Stands and Cases | How to Care for Custom Knives | Site Table of Contents | |

| Top 22 Reasons to Buy | Business of Knifemaking | Tactical Knife Sheath Accessories | Handles, Bolsters, Guards | Knife Making Instruction | |

| My Knifemaking History | Professional Knife Consultant | Loops, Plates, Straps | Knife Handles: Gemstone | Larger Monitors and Knife Photos | |

| What I Do And Don't Do | Belt Loop Extenders-UBLX, EXBLX | Gemstone Alphabetic List | New Materials | ||

| CD ROM Archive | Independent Lamp Accessory-LIMA | Knife Handles: Woods | Knife Shop/Studio, Page 1 | ||

| Publications, Publicity | Universal Main Lamp Holder-HULA | Knife Handles: Horn, Bone, Ivory | Knife Shop/Studio, Page 2 | ||

| My Curriculum Vitae | Sternum Harness | Knife Handles: Manmade Materials | |||

| Funny Letters and Emails, Pg. 1 | Blades and Steels | Sharpeners, Lanyards | Knife Embellishment | ||

| Funny Letters and Emails, Pg. 2 | Blades | Bags, Cases, Duffles, Gear | |||

| Funny Letters and Emails, Pg. 3 | Knife Blade Testing | Modular Sheath Systems | |||

| Funny Letters and Emails, Pg. 4 | 440C: A Love/Hate Affair | PSD Principle Security Detail Sheaths | |||

| Funny Letters and Emails, Pg. 5 | ATS-34: Chrome/Moly Tough | ||||

| Funny Letters and Emails, Pg. 6 | D2: Wear Resistance King | ||||

| Funny Letters and Emails, Pg. 7 | O1: Oil Hardened Blued Beauty | ||||

| The Curious Case of the "Sandia" |

Elasticity, Stiffness, Stress, and Strain in Knife Blades |

||||

| The Sword, the Veil, the Legend |

Heat Treating and Cryogenic Processing of Knife Blade Steels |