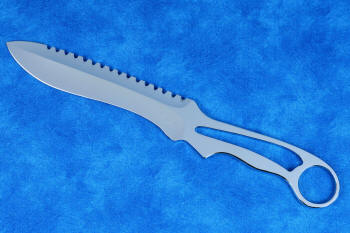

Xanthid (Reef) Custom Knife

"Xanthid" (Reef) Custom Professional Tactical Dive Knife

- Size: Length overall: 13.0" (33.0 cm), Blade Length: 7.0" (17.8 cm), Thickness: 0.205" (5.2 mm)

- Weight: Knife: 7.1 oz. (201 grams) Sheath: 11.1 oz. (315 grams)

- Blade: 440C high chromium martensitic stainless steel blade, T3 deep cryogenically treated with triple tempering to 58 HRC, mirror polished

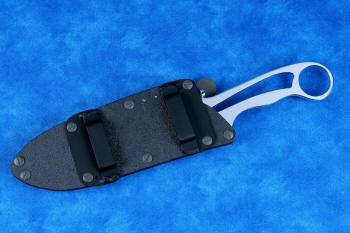

- Sheath: Locking-tab-wedge hybrid tension in kydex, anodized 5052H32 aluminum, blackened and passivated 304 stainless steel, anodized 6AL4V titanium

- DCAM: Dive Calf Accessory Mount in SCUBA rated 6.7 mm neoprene foam rubber, nylon, polyester, polypropylene, acetyl

- DBAM: Dive Belt Accessory Mount in SCUBA rated 6.7 mm neoprene foam rubber, nylon, polyester, polypropylene, acetyl, with two belts

- Hardware, Fasteners: 304 stainless steel, blackened and passivated, 6AL4V anodized titanium

- Duffle: 1000 Denier Cordura Ballistic Nylon, polypropylene, polyester, nylon, blued steel, embroidered tags

- Knife: Made for a great client to his

specifications, this is my Xanthid tactical dive knife, the same

knife I've made for counterterrorism response professionals.

"Xanthid" is the family of crustaceans composing the most toxic and

deadly crabs in the sea. Atypically, this pattern is also known

in my pattern inventory as "Reef." This is a true professional grade

custom tactical and working dive knife, made completely for wear in

the salty marine environments encountered in the ocean. It is an

ultimate dive knife, built for long lasting durability, extremely

secure wear, light weight, and

serious use. The knife is upgraded somewhat from previous models,

with some important distinctions.

- The steel I chose for this knife is 440C high chromium martensitic

stainless steel, my most requested steel for a reason. When

properly treated, it's a dependable, reliable workhorse of

extremely high corrosion resistance, good toughness and high

wear resistance. The extremely high chromium of 440C along

with the high carbon and moderate molybdenum results in

profuse chromium carbides, increasing corrosion resistance

as well as wear resistance. To bring this steel to its

zenith, I used my proprietary T3 deep cryogenic process in

heat treating this blade; it's a highly detailed, extremely

sophisticated process that takes 33 individual steps and

takes over a week long. The result of this is an incredibly

wear-resistant blade that has extremely high carbide

development, fine grain, and extremely high corrosion

resistance. Asperity is reduced; the microstructure

development is superior to any other typical handmade knife,

and far above any factory or manufactured knife. This is,

simply put, 440C at its very finest advanced condition.

- The knife feels feels much more

substantial than it looks in a photograph. I've milled and

polished the entire handle so that corrosion can't start and

the knife is easily cleaned with just a rinse in clear water. The

large handle has plenty of curvature to grip and the rear

finger ring accommodates the hand in either forward or

reversed grip style. The ring and the central handle

millwork can both accommodate a lanyard, and when the

lanyard is hitched in the central

position, the lanyard won't get in the way of the finger ring

for use. The large front quillon stops the hand from moving

forward on the blade, and the thumb rise protects the thumb

from the serrations. The serrations are my incredibly sharp

hammerhead serrations; they will rip through just about

anything short of metals. I've put plenty of length, about

5.5" (14 cm) of them on the blade, and the central thick

spine of the double-edged knife supports them well. The

first 1.5" (3.8 cm) of the blade tip on the serration

side is razor keen for easy piercing. The main

cutting edge is keen beyond belief. I can make it this way

because of several properties. First, the sophisticated

treatment of this steel produces an superior microstructure,

capable of extremely small grain size, leading to great

strength. I've tempered the steel to 58 HRC, so the blade

has substantial toughness and resistance to fracture. The

hollow ground edge is very thin, and in the recurve, it's

stunningly sharp. This is because the geometry of a hollow

grind and a recurve both together creates the very thinnest,

and then sharpest cutting edge possible. The thickness

behind the cutting edge at the recurve is only 0.015" thick,

that's less than the thickness of four sheets of notebook

paper! Though the steel behind the edge is twice as thick at

the belly of the blade, I made the recurve this way so the

knife will always have the capability to slice cordage,

line, and rope at the recurve, while the point and belly are

expected to do heavier work, like piercing and ripping. The heaviest work can be done

by flipping the knife over and using the aggressive

serrations. The balance point of the knife is exactly at the

ricasso, and it feels quite large in the hand.

- Sheath: The sheath is an advanced evolution of my hybrid tension-locking sheath,

a positively locking, wedge-opening model.

- Materials: It's built on a frame

of 5052 H32 corrosion-resistant high strength aluminum alloy welts.

The individual welts are then anodized for a full mil of thickness,

twice the thickness of typical anodizing. The anodizing creates a

built-up near-ceramic hard surface on the aluminum, and it's

entirely corrosion-resistant and non-conductive. It's permanently

dyed (in black) and sealed with a solution that inhibits ultraviolet

degradation of the dye and anodized surface. In fact, all of the

aluminum components in this assembly are the same alloy

and are treated this way; this is

the most advanced condition for marine use. The sheath front and

back are double-thickness kydex, twice the thickness of typical

knife sheaths, and the sheath is bonded with waterproof marine-grade

cement and secured with darkened and passivated 304 stainless steel

Chicago screws.

- Layout: As with all of my sheaths, they are built on a 2.5"

center hole pattern, so the components can be moved around an

mounted in various positions on the sheath. As with all

of my tactical sheaths, this one is completely reversible

for as many wear options as possible. Most of my accessories can be used on this

sheath, including any new ones I develop.

- Horizontal Belt Loop Plates for horizontal belt or webbing wear,

welded for ultimate strength and light weight,

reversible, and in black anodized aluminum.

- Flat mounting straps for rigid clamping to

webbing, belts, or gear in vertical or horizontal

orientation in black anodized aluminum.

- Low profile belt loops

(footman's loops): for tactical webbing belts with

maximum .190" thickness and 1.5" width in black

anodized aluminum

- High profile belt loops

(footman's loops): for tactical webbing belts with

maximum .250" thickness and 1.5" width in

black anodized aluminum

- High profile wide belt loops

(footman's loops): for tactical webbing

belts with maximum ..250" thickness and 1.75" width

in black anodized aluminum

- Lanyard: SCUBA rated, not shown in photos

- All necessary stainless steel hardware, fittings, fasteners and tools for mounting, moving, and adjusting

- Locking-Tab-Wedge (LTW): An advanced feature of

this knife sheath is designed for dive use: the security and retention

mechanism. I've used my standard hybrid tension lock, so the knife

can be retained with the pressure of an anodized 6AL4V titanium

dog-leg spring, and I've included a pair of those so the user can

choose which strength to apply. Normally, in an emergency, the ball

and spring can be deflected with a hard tug, and I wanted to leave

that choice to my client if he wished for a standard setup. However,

in the ocean, it's more important to have a more secure, even

locking retention method, and to not have to struggle

or use two hands to re-sheath

the knife. This sheath includes my locking-wedge-tab. These three

words are the best to describe the LTW mechanism. When sheathed, the

small tab can be rotated over the top of the titanium spring, preventing it

from moving away from the knife axis, effectively locking the knife

in the sheath. When the user needs the knife, he simply pulls the

tab toward his hand with his thumb, and the locking flat of the tab rotates

off the spring, and the wedge lifts the titanium spring and ball

away from the knife, clearing the blade, the serrations, and leaving

the entire mouth of the sheath open. Then, the knife is unsheathed.

It takes much more effort to describe it than to use it; the motion

is natural with the thumb. You wrap your hand around the handle,

pull-flip the locking-tab-wedge, and extract the knife. Reinsertion

is just as simple; you slip the knife in the sheath (as the ball and

is completely out of the way) and then use the thumb to

push-swivel the

tab forward, closing the ball on the thumb rise, and locking the

knife in the sheath. Because I've built these sheaths to be

completely reversible, I've included two locking-tab-wedges, one for

each side. If my client wants to forego the locking-tab-wedge

entirely, he simply replaces the post mounted to the rotating tab

with a standard Chicago screw post, and he then has the typical

hybrid tension-lock. Improving this design is representative to

my commitment to excellence in service to the people who

purchase and depend on these knives, and it's an honor to design

these for the hardest of environments and use.

- Knife/Sheath wear options: A knife is worn, not

carried, so this is critical for a tactical dive knife. In addition

to typical wear positions (on a belt, on PALS webbing, body armor,

or gear and equipment bags, packs, and frames), this knife has some

very specialized wear gear:

- DCAM (Dive Calf Accessory Mount): This

is my calf-mounted assembly, one that is worn

comfortably against the bare skin underwater, can stay put while

active, yet keep the razor sharp edge and deadly point of the

Xanthid immediately accessible. It is constructed

entirely of waterproof dive-rated materials, and is secure as it

can possibly be, wrapping around the calf with three strap

mounts of wide, strong webbing. The base is soft, thick 6.7 mm

neoprene foam with textured body-contact rubber on the inside,

and tightly woven nylon on the outside. This is very heavy

wetsuit material, and the mounts for the straps and webbing are

backed with soft Velcro® loop stitch pads to back up the

stitches. The webbing is secured with bonded polyester

waterproof thread, size V-138 for extreme durability. The

outside of the wrap is sealed and bonded with nylon wetsuit

material, stitched with flexible nylon. The sheath tail pocket and

anti-flop shock cord are double thickness elastic nylon; the

tail pocket is three inches deep, and the anti-flop shock strap

is .75" wide. The sheath body clamps rigidly under the center web, and is trapped

between the webbing and the wrap, so is extremely secure. The

buckles are all 1.5" cam lock Acetyl plastic and are infinitely

adjustable yet can be quickly released in an emergency. This is

a very comfortable rig, and will be a favorite wear accessory in

the future. Photos

below are of "Synan," but the rig is the same. My model

is my Grandson, USMC Malachi Beauchamp.

- DBAM (Dive Belt Accessory Mount): Also

included is accessory that allows the knife to be worn in

the middle of the back or the front, with horizontal

orientation. This is the DBAM, Dive Belt Accessory Mount,

which I made of 2" wide polypropylene webbing with Acetyl

buckle, the same material as the Sternum Harness for my

counterterrorism knife sheaths. The belt accommodates the

width of the span between the flat clamp straps when worn

horizontally, so the sheath clamps rigidly to the belt. The

custom pad is made of the same 6.7 mm wetsuit foam neoprene

as the DCAM, edge stitched and sealed, and held in place

with two 3" wide double thickness elastic nylon straps. The

pad stays in place, protecting the body from the sheath, and

it's a comfortable, secure rig in or out of the water. I've

also included an extra-length belt for a variety of wear

sizes. Photos below are of "Synan," but the rig is the same. The model is my Grandson, USMC Malachi Beauchamp.

- Standard Wear Options: the kit includes

all of my basic standard wear mounts; belt loops, flat

clamping straps, horizontal belt loop plates, and all

necessary hardware, screws, fittings and tools.

- Containers, Instructions, Archival: included are tin plated

steel containers for the fasteners and hardware, and the

instructions for the rig including a checklist for the

kit. Included is an engraved co-extruded acrylic archival plate.

- Duffle: One thing I found out over the years

was a need to store these components that was as tough and durable

as what they contained. This is why I make the duffles, in my

studio, by hand. I make them in 1000 Denier Cordura ballistic nylon,

which is coated on the inside with polyurethane for moisture

resistance. This is some very tough stuff, and I triple-stitch the

seams, all in heavy polyester thread. I've included steel D-rings at

the zipper stops on the ends for several reasons: to mount accessory

straps or carry options, to clip accessories, and to oppose the

zipper when pulling open. Otherwise, you have to pinch the material

to open the zippers with one hand and pull the zipper pull with the

other. I've used double zipper pulls, for quick and easy access, and

stitched on 2" wide webbing straps in polypropylene, permanently

mounted in position on the duffle body, and they are reinforced and heavily

stitched on the inside of the duffle, as well as the handle areas.

The design of the duffle is a box-end, so that the duffle stores

neatly. It has my (rather handsome) patch signifying "Quality

Without Compromise" and my maker's mark. Opposing that is a hook and

loop stitched tag mount, with a removable embroidered identifier of

the knife pattern. This is important when clients have more than one

knife. These duffles are so great, I have clients buying them

alone without a knife, for their friends and other stowed gear!

- This is a great dive knife kit, ready to take to the water, and

it was an honor to make it!

Thanks, P. K.!

They arrived today. I expect perfection and you delivered as always.

The kits were a surprise to me. I know this sounds stupid to you, but, I am so use to

a masterpiece and a sheath to be put on display. The embellishments, on the weapons, cause

one to look at them as art pieces and not weapons of war. The kits bring home the seriousness

of your works and the need for full kits. In the future I will get full kits.

I would guess the majority of patrons do not truly understand what you do. The trolls and detractors

miss the mark completely. Your creations mean the difference between life and death.

Yours Truly:

P.

Please click on thumbnail knife photos