Please note: I do not sell woods or wood stock.

I only use woods on my own knife handles.

This page contains:

Questions, answers, pictures, descriptions, and synonyms of domestic and exotic hardwoods used in modern knife handles,

knife stands, cases, and blocks.

It is my goal to make this the best page of exotic woods

used in knife handles on the net. I've worked hard to

illustrate and describe the woods used in custom knife handles,

components, stands cases, scabbards, sheaths, and fittings. Although

I'm better known for my gemstone custom knife handles, I've worked

extensively with woods in this field for over 30 years. I'll

continue to add to this page as I complete new projects and find

pictures of other uses of these fine woods. All of the knives

pictured on this page are my own, all the woods listed I've

personally worked with. The comments are based on my personal

experience with these woods.

Remember, woods vary in appearance and texture even within the

same board, so there is no absolutely uniform dictate on a

particular wood's performance. Being porous, woods can absorb and

release moisture and other agents that they're exposed to which will

change their makeup, appearance, and sometimes size.

I am committed to making completely and clearly the best knives in the world.

--Jay Fisher

More

Page Sections:

-

Answers to the 11 most commonly asked questions about wood used in modern custom knives

- Why wood knife handles?

- What is the difference between hard woods, soft woods, and just plain wood?

- Are there original or unique hardwoods just for knife handles?

- What makes one wood usable on a knife handle, and another not?

- What about Dymondwood®, Pakkawood®, and Staminawood®?

- What about stabilized woods?

- What is the difference between a burl, straight grain, or wavy grain, figure, and texture?

- Aren't the darker woods harder than lighter colored woods?

- Are some woods more expensive than others?

- What about the names of hardwoods?

- What about general descriptions of these hardwoods?

- Notes, disclaimer about web photos and wood appearance

- On to the woods!

-

Woods I have currently available for projects

- Details and pictures on

60 of the most commonly used woods in custom knives

- Over

340 alternate and local names for these woods

More

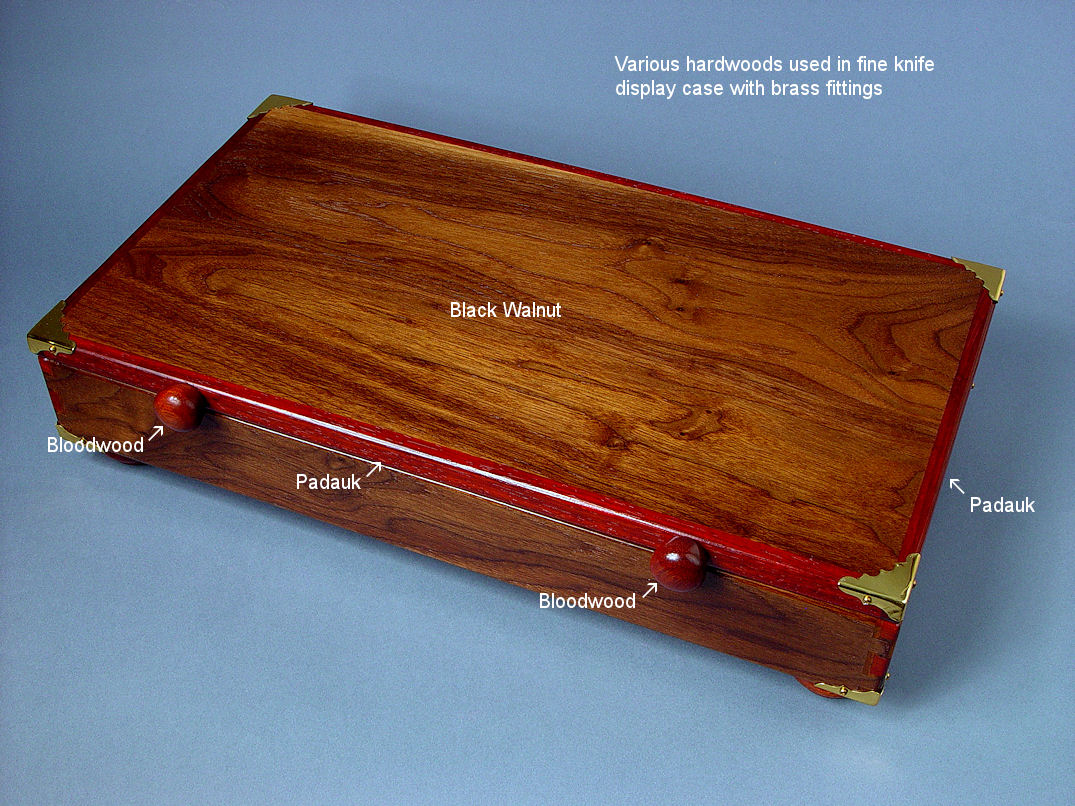

More about this "Duhovni Ratnik"

and case

Wooden knife handles have been used ever since the invention of the knife. Woods are organic, warm to the touch,

comfortable to hold, and can be long lasting. Wood handles are used on nearly every kind of fine tool,

instrument, or even vehicles, including a ship's wheel. Hardwoods exhibit a distinctive class of fine taste, and

throughout time, will always be cherished for their value. Hardwoods compliment

metals very well, and are artistically sound, choice exhibits. In knives, they

have been, and will always be a standard.

Back to Topics

More

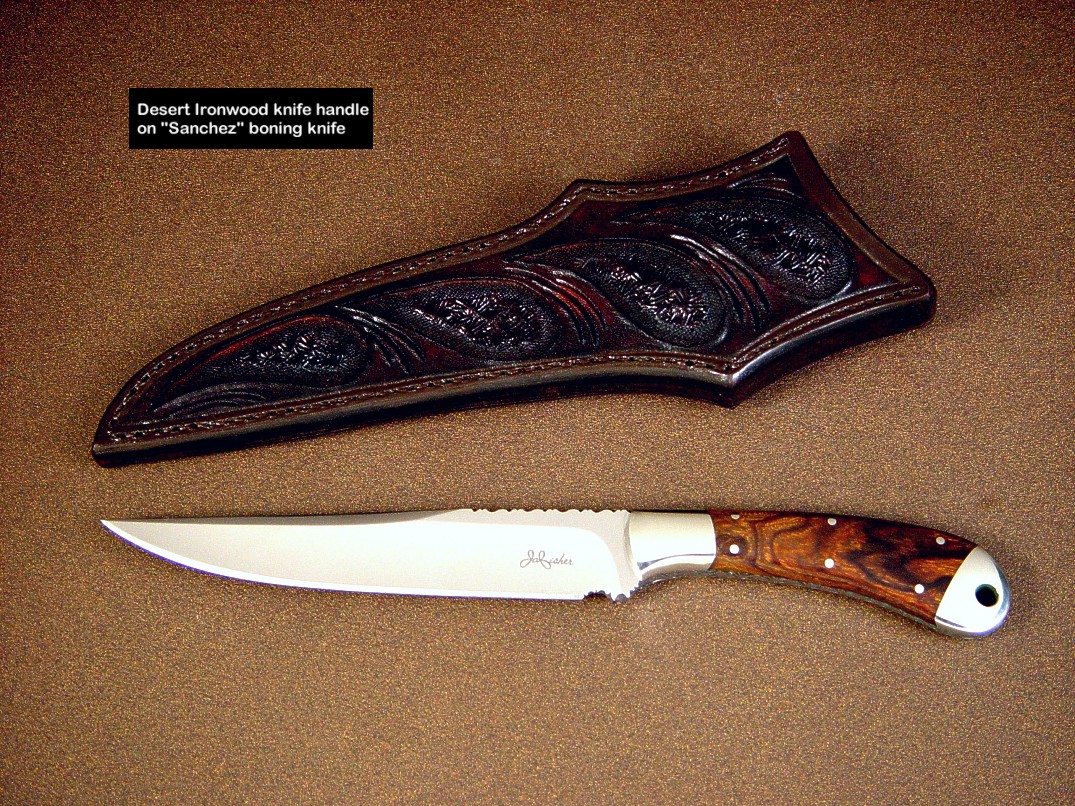

More about this "Sanchez"

The word "hardwood" actually refers to trees that are deciduous. Deciduous trees are

actually angiospermous trees: trees that loose their leaves every winter, bear flowers, and have broad leaves.

Softwoods refer to conifers. Coniferous trees have needles or are evergreen, and have cones.

Because most of the deciduous trees have wood that is physically dense and more resistant to penetration,

they were coined "hardwoods." This may not necessarily be the case though, as some conifers

have very hard, tough wood, and some deciduous trees have wood that is fairly soft.

There is also confusion about which part of the tree has the most usable wood, and in knife handles,

it's almost always the heartwood that is used. The heartwood of the tree is the inner core, extending

from the pith to sapwood, where live cells have been converted to gums, resins, minerals, and other substances

resistant to decay. The heartwood is almost always harder and more durable than the sapwood. The sapwood is

the living layers of the tree, is almost always lighter in color and density than the heartwood, and is more

permeable to liquids and susceptible to decay.

Back to Topics

More

More about this PJLT

Looking at the availability of various exotic hardwoods, one would think that only a dozen or so rate

use for a custom knife handle. This is simply not true as there are hundreds of applicable woods,

and many of these woods exist in a group that has hundreds of species. For example, in the family

of ebony (Ebenaceae), there are about three hundred species of shrubs and trees distributed throughout the

temperate and mild regions of the world.

Though it may be said that each piece of wood is unique, many are so uniform that

distinctive differences cannot

be claimed. In example, one piece of ebony looks pretty much like another, uniform and black. But most woods

exhibit some figure, color variation, or pattern that makes them attractive.

In other species, every piece of wood is different, and slabs cut from

the same block look like distinctly different woods.

Back to Topics

More

More about this Desert Wind

Woods used for handles (any kind of handle) must be fairly hard to be long lasting.

They must be durable, able to hold fine curves and thin sections like the high points of finger grooves,

flutes, and bolster dovetails without breaking, chipping or splintering. They must be smooth

to the hand, polish well, and fairly close-grained so debris, staining, and

contamination is kept at a minimum. They must be attractive. Another point

not often considered is their tendency to expand an contract with moisture and

temperature changes. All organic materials change to some extent. Good

knifemakers strive to use stable woods and minimize movement that can loosen the

wood handle from the metal knife tang. Makers also judiciously apply

pins, screws, and attachment hardware to secure the wood to the knife

tang, and should also bed the wood with modern adhesives and compounds

to secure and seal the critical wood-to-steel junction.

Back to Topics

More

More about this Paraeagle

These are actually plywood products, usually constructed from birch.

Dyes are vacuum-impregnated into the wood, then the wood is pressure impregnated

with polymer or phenolic resin at very high pressures, then highly

compressed into plywood blocks. With the high compression rates and

solid massing of the material, this creates a very dense, tough, and

solid wood product, that is pretty much waterproof when wet. Though

I don't use these often (some of the colors are quite garish), some

clients request them and I'm happy to accommodate them. These

stabilized laminates are very durable, polish brightly, and are long

lived. Read more details about these manmade wood products and see a color chart and comparison on

my

"Manmade Knife Handle Materials" page at this bookmark.

Back to Topics

More

More about this Mercator

Woods that are stabilized are woods that are usually too weak, too porous, or too plain to be used without treatment.

Like the laminates described above, dyes are sometimes impregnated into the wood, then

the wood is pressure-impregnated with polymer or phenolic resin at

very high pressures. With the high rates of pressure, this creates a

very dense, tough, and solid wood product, that is pretty much

waterproof. I use stabilized hardwoods like Box Elder Burl,

Buckeye Burl, Redwood Burl, Maple Burl and a host of others.

The process creates a very durable plasticized wood, unique in color that

polishes brightly, and is extremely durable and long lasting. For woods that are not

naturally self-sealing, oily, or resinous, this is the

only way to get woods that are waterproof for kitchen use and marine environments.

Here are some examples on this page of stabilized woods with

photographs of finished handles:

Back to Topics

More

More about this Izanami, Izanagi stand

There are many terms used to describe woods.

In the individual wood type descriptions below, you'll find

descriptions of hardness, durability, and appearance. Though all of

these terms may not be used in my work (I seldom taste the hardwoods,

unless I'm really hungry), these are the accepted and general

descriptive features that identify specific woods in most scientific and

detailed texts.

- Grain: the direction and orientation of wood cells, particularly the fibrous elements. There are six general

types of grain:

- Straight grain

- Irregular grain

- Diagonal grain

- Spiral grain

- Interlocked grain

- Wavy grain

- Figure: The natural design or pattern seen on the surface of the wood and may include:

- Growth rings

- Vascular rays

- Knots, burls, buttresses, crotches, swells

- Variations in color

- Blisters, quilting, ribbon, stripes, wavy, fiddleback

- Texture: the size and variation of size of the wood cells; the "feel" of the wood surface

- Coarse: wide vessels, broad rays

- Fine: narrow vessels, thin rays

- Even: woods that show little or no contrast between seasonal growth

- Color

- Odor and Taste

- Luster: the ability of the wood to reflect light

All of these features and distinctive attributes determine the value, longevity, and

durability of woods used on knife handles.

Back to Topics

More

More about this Hooded Warrior

Not every light colored wood is as soft as pine.

Not every dark wood is as hard as ebony.

It is a common misconception that darker woods are harder and thus, more

desirable than lighter colored

woods. It reminds me of the 1970s when every den had to have dark or walnut colored paneled walls, furniture,

and accessories. This may be the very reason that these dens were later called man-caves, because they were

almost always dark. Guys would stain pine to a walnut color to darken it, and make it seem more valuable, as

the most valued North American hardwood is American Black Walnut. But I'm sure the practice goes back much

further, as even in historic pieces, they were ebonized to make the wood seem richer and more valuable.

There is often a persistent belief that the darker woods are harder, and more durable as well as more

masculine and bold in visual punch. This is wrong; there are many very hard, tough, and durable woods that

are light in color and well-outlast darker woods like walnut. Woods like Olive, Bois d' Arc, Peach, Pear,

Apple, Pecan, Hickory, and Ash are all very hard, dense, and durable woods, and every one of those will

outlast Walnut. Even Red and White Oak are harder and more durable than European, American, or Tropical Walnuts.

Simply put, darker does not mean harder or more valuable.

Back to Topics

More

More about this Macha Navigator

More

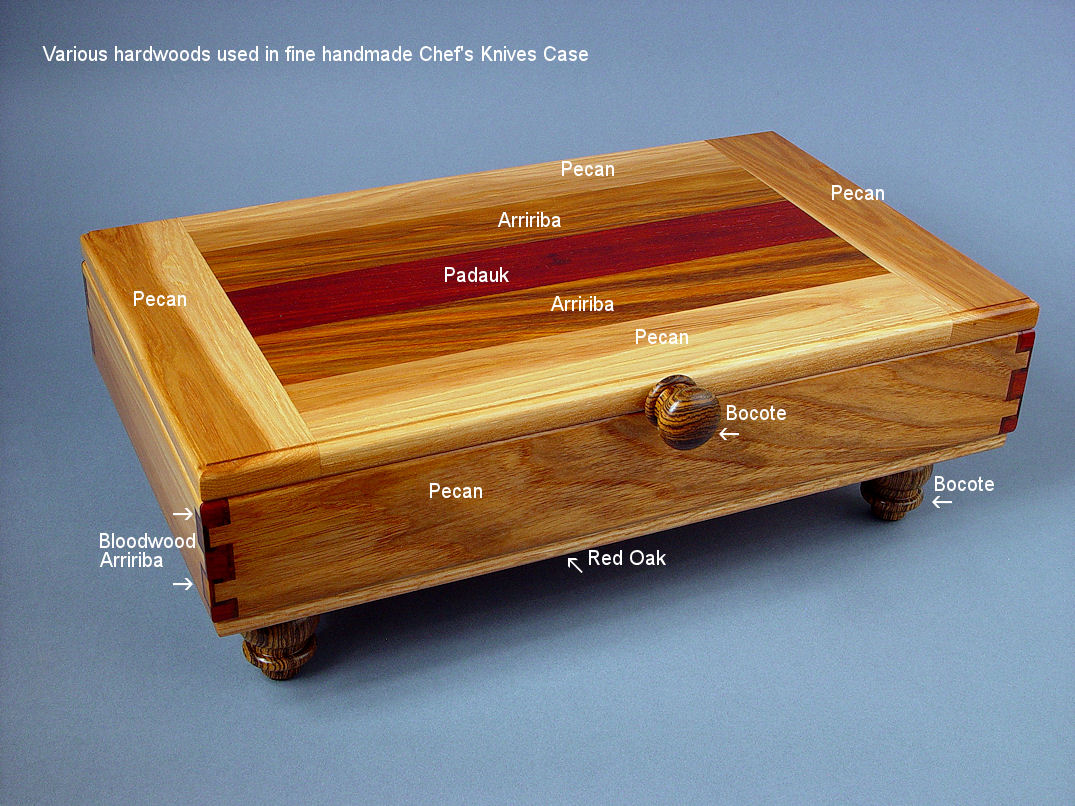

More about this Chef's Knives

Set and case

You bet they are. Woods like snakewood and

pink ivory come at a high price. Sometimes, certain

cuts of woods (like Desert ironwood and burls) that show plenty

of figure and interest cost up to ten times per handle for the knifemaker, a

cost that increases the value of the knife, and the final cost of the knife to

the client. There is also a lot of misinformation on the internet and in

reference books about woods, their availability and their value (a good example

is the listing about Desert Ironwood below).

Environmentalists will decry all cutting and

usage of wood, yet most woods are completely renewable, and many sources of

"rare and exotic" woods we use come from wood farms and plantations. It is in

their best interest to hype woods as extremely rare and irreplaceable, as this

will drive the price up, giving suppliers more profit. Could it be worthwhile

for lumber interests to allow some environmentalists claims to go unchallenged

while the price of wood increases because of "rarity" or "limited supply?"

There is also a difference in use and volume.

The smaller a piece of wood is cut, the higher the price per pound. For example,

go to a hardware store and look at a piece of

all-thread rod. A one foot bar will cost three to five times as much per foot as

a six foot bar. Why? Is the cut more expensive? Is the little piece more

valuable per inch than the larger one? No, the store knows that if you don't

need a six foot piece, then you're willing to pay more per foot for a smaller

piece just to get the job done. Knife handle scales are that way. You can go to

Mexico and pay $30 US for fifteen pounds of ironwood, enough material to make 30

or more handles, or you can buy a pair of scales from a knife making supply

company for $30 each. Sure, you sometimes get to pick and choose the particular

cut, and they do tend to weed out the unusable scrap. But sixty times the

price? Makers and knife clients will pay that though, if they think they're

getting something original. Yet there are thousands and thousands of knives out

there with similar handles.

There are more expensive woods, and there are

less expensive woods. Many cost more than the steel in the blade. The cost is

not usually dependent on durability, hardness, or longevity of the wood handle material,

it is almost always the appearance, and nearly all of them are beautiful in

their own way. Of course, I have to consider my costs, working costs and

expendables, and rarity in the final evaluation of the price of the knife, case,

stand, or artwork, so that too, figures into the pricing.

Back to Topics

More

More about this Hooded Warrior

Hardwood names can be bewildering. Every

country has a host of names all for the same wood, other countries name the same

wood in their host of names, then dealers and suppliers add their own

name to the wood, and before you know it the wood has twenty different names.

Take Ironwood, for instance. There is a lot of confusion as the term

"Ironwood" refers to many trees in many nations. The Latin term iron wood

is Pau Ferro, another host of descriptive wood types bear that name. It

seems that every country has some hard wood or tough tree that deserves the name

Ironwood, and there are over 80 distinct species from all over the world

that are commonly named Ironwood. Common trees that bear the Ironwood

name are: American hornbeam, Black Ironwood, Desert

Ironwood, Olive trees, Hop Hornbeam, Persian Ironwood, Ipe, Ekki, Rose Chestnut,

Ceylon Ironwood, Australian Ironwood, and even Lignum Vitae, the densest wood

known. Then there is Pau Ferro, Pao Ferro, Pao Fierro: from two different

continents, all different trees. Some of the woods referred to have several

species (and some have hundreds of species!), so the traits I've experienced and

noted may not apply to all the woods of the same name. At the

synonym list at

the bottom of this page, I've tried to nail down the types of each, including

cross referencing the common and trade names of the woods. This page consists of

a lot of research, and I learned a lot compiling it.

Back to Topics

More

More about this Desert Wind

I've compiled quite a bit of information on

this page, and in doing so, found a lot of errors in the texts of reference

manuals on woods and on the internet. Some woods are listed in the books as

"non-durable," and in my experience, they are extremely hard, durable, and long

lasting. Many woods are listed as rare or nearly impossible to get, but look on

the internet and there are literally hundreds of sources to acquire them.

The information and descriptions below are derived from nearly 40

years of my experience using the woods for knife handles, cases, stands,

and in other cabinet, furniture, and turning projects. So, while many

dealers and suppliers of exotic and domestic hardwoods make claims about

their usefulness and applications, I've actually used them: sawn, cut,

drilled, carved, sanded, and polished them, and my clients have used

them in the field, in their collections, and even in active military

combat. I've applied that real world experience with valid information

to nail down a specific description of the wood.

Back to Topics

More

More about this Azophi

I've tried my best to give an

accurate color and figure rendering of these exotic and domestic

woods and handle materials. Some things to consider are:

- some woods change color over time (mostly due to regular oxidation processes)

- some woods change appearance when exposed to fluids or contaminates (some even change with

normal oils from human hands)

- the wood selected for handle material may vary in grain, grade, and color (I can't regulate

the exact appearance, even in the same board stock).

- there may be additional considerations that apply to your choice in a knife handle

material (like thin sectional support, impact resistance, and texture)

- no two pieces of wood are alike, even when book-matched.

- There are some considerations

also for photographic rendering of these knife handle materials:

- The color may vary depending

on original photography, scanning methods, color rendition of

editing programs, and the color setup of your monitor

- The color of your actual handle may vary depending on the above factors and what light

and intensity you view it in (the color of light depends on the

source; florescent lighting, incandescent lighting, and daylight

all vary greatly in color)

- The grain and figure may be more or less pronounced

than the actual material. This is also due to

limitations and setup in the computer viewing

components, like the photo editing program, your monitor

and settings, and the horribly weak limitation of the

internet overall, which limits color, contrast, and

definition.

- Some pictures have been borrowed from suppliers and sources, and I can't absolutely

guarantee their accuracy (but they're very close!)

Back to Topics

More

More about this Alegre

Here is a list of hardwood materials I've used in custom knife handles.

Many of these I have in stock, and most are available if I don't stock them.

Please remember that

I don't sell wood stock, only use woods on my own knife handles!

Back to Topics

Here are the woods I currently have available for projects. I may have small amounts (enough for one or two knives) or I may have large planks

and many board feet. Over the decades, one amasses many types and amounts of woods, and they come from all over the world.

The amounts and species vary, and I'll try to keep the list up to date.

Please note that I don't sell woods!

This first list details woods available for handles.

See below for woods available for sculptural stands, cases, displays, blocks and larger items.

- Amboyna Burl

- Apple

- Apricot

- Arririba (Canarywood)

- Birch: Stabilized, Dyed, Pakkawood, Dymondwood

- Blackwood, African

- Bloodwood

- Bocote (Cordia)

- Bog Oak (Ukraine)

- Bois d'arc - Osage Orange

- Bubinga

- Cacique

- Cocobolo

- Courbaril

- Desert Ironwood

- Ebony, Gaboon, Royal Striped

- Eucalyptus: Curly, Quilted

- Eucalyptus, Gum, Red Burl

- Goncalo Alves

- Guayabillo

- Honduras Rosewood Burl

- Honduras Rosewood

- Imbuyia

- Jobillo

- Kingwood

- Lacewood

- Lignum Vitae

- Madagascar Rosewood

- Madrone Burl

- Mahogany, Quilted

- Maple: Fiddleback, Bird’s Eye, Burl, Hard, Rock, Straight

- Maple: Big Leaf Burl

- Maple: Spalted

- Mesquite: natural, stabilized

- Mora (Guatemala)

- Olive

- Padauk

- Palm, Black

- Pao Ferro

- Peach

- Persimmon

- Pink Ivory

- Purpleheart (Amaranth)

- Quebracho (Argentina)

- Red Coolibah Burl

- Redheart

- River Gum Burl

- Rosewood, East Indian

- Snakewood

- Tamboti - African Sandalwood

- Thuya Burl

- Tulipwood

- Wenge

- Zapote

- Zebrawood

- Ziricote

This second list details woods available for sculptural stands, cases,

displays, blocks and larger items.

See above for woods available for

handles.

The amount, volume, and character of these woods varies, so not all

are available for all projects.

Back to Topics

Wood Handle Material Descriptions with Thumbnail Photos

- African Blackwood

Dalbergia melanoxylon:

- Origin: Mozambique, East Africa. Exceptionally hard

and dense species, black, but not as solid black grain as ebony. Straight

grained. It is actually a rosewood, not an ebony. It makes a great knife

handle, and is strong, long lasting, a bit aromatic and holds details and

pins well. It is actually more stable than ebony. Used in musical wind

instruments (like clarinets, oboes and bassoons), bearings, pulley blocks,

carvings. Polishes smoothly, holds well, oily and resinous.

- Amaranth (Purpleheart)

Peltogyne spp. F. Leguminosae:

- Origin: Tropical America from Mexico to Brazil.

Moderately hard an medium dense hardwood, initially brown when cut, but

turns dark purple when oxidized or heated. Although a bit open grained for

knife handles, it offers interesting color patterns with torch work.

Straight grained. Polishes easily, slightly porous. Occasional streaks of

grain with white lines. Used also on cabinets, heavy outdoor construction,

gymnasium apparatus, diving boards, skis, chemical vats.

- Amboyna Burl

Pterocarpus indicus:

- This wood is widely touted as the world's most expensive burl,

but I'm not sure if that's true, since it's readily available in

literally hundreds of online web sites, wood distributors, and

sources. It is a strikingly beautiful wood, and a great variety of

appearance can be directed by arranging the cuts of the wood to show

different figure. It's a wood that originally came from the island

of Amboyna (thus the name) but is well known by many different names

today, and mostly originates in Borneo and grows throughout the East

Indies and the Phillipines. The wood is fairly hard, dense, and solid, and works well

with few cracks or checks. It does not easily oxidize or change, so

is very stable. It's very difficult to tell Amboyna from Thuya burl.

The wood was widely used in furniture built in the Empire period

(1804-1814) and was scarce during the last century, but now is much

more common. It looks great on a knife handle, but its main usage

historically was in veneers. The wood is also used commonly in

non-burl form, simply known as amboyna. Look to

the list below to see the many other names for this wood.

- Arririba (Canarywood)

Centrolobium spp.:

- Origin: Brazil. From a small tree, color yellow to

tan with red and black streaks. Used also in naval architecture, cabinet

veneers. Polishes well, is very stable, holds its color which is bright and

interesting. Tight grained, stunning in knife handles, knife hard sheaths

and scabbards, and stands. Straight grained, some wavy grain.

- Australian Blackwood

Acacia melanoxylon:

- Origin: Hundreds of species of the Acacia genus:

South America, South Africa, India, Australia, Tasmania. Despite the name,

the heartwood is reddish brown, bands of dark brown with a reddish tint.

Some oxidizes deep red over time. Makes a dense, tight, solid and long

lasting knife handle. It's very hard, moderately dense, straight grained,

polishes very brightly, with a fine finish, and is stable. Used in high

quality furniture, billiard tables, gun stocks, ornamental turnery and

musical instruments.

- Birch Laminates (Stabilized)

usually Betula papyrifera:

- Origin: Factory modified and created from birch.

These laminates are sold by the name Dymondwood®, Pakkawood®, Staminawood®,

and others are vacuum dye impregnated and then pressure treated compressed

laminate plywood products. Most of the wood used is birch, and these composites

were made currently by Rutland Plywood Company, before a fire

destroyed their plant. Now other companies are making this type of

laminate. These are tough,

durable, long lasting and waterproof wood products, and sometimes have bold

colors, stripes, and figure. They are a popular wood product for knife

handles, so yes, I use them too, occasionally. The shocking patterns can

look a bit ridiculous, so I try to stay away from the types that look like a

carnival clown. But, since I do custom orders, and clients get what they

want, some opt for these products because of durability as well as color,

and they are quite durable on the knife handle. Important: see also

my page

on man made handle materials which has extensive information on these wood

products at this bookmark.

- Bloodwood (Satine)

Brosimum paraense:

- Origin: South America. This is a fairly common

hardwood, bright blood red. Moderately hard, takes a good polish, very

durable and long lasting. Straight grained, heavy. I've used this in custom

knife handles for decades, and in stands, hard sheaths, and fittings, it lasts

very well with moderate sealing with wax or cyanoacrylate. Used in turnery,

fine cabinets, ornamental woodwork. There are several species of this group,

and some distinguish between Satine, Bloodwood, and Cacique. The only

differences I've seen is that Caciqe occasionally has small white deposits

in some of the grain (silicates).

- Bocote (Bucote)

Cordia alliodora:

- Origin: Mexico, Central and South America. A very

dramatic figured wood, with light tan background and sometimes wild dark

brown stripes in both straight grain and knots, occasional burls, and waves.

Medium density, very porous, takes sealers well, somewhat permeable. In

knife handles, great care must be used in finishing, as the grain picks up

polish and metal swarf, but once finished, is a bold and long lasting

handle. Used in fine cabinetry, furnishings. Mildly fragrant. Porosity can

be a problem when finishing, as it takes polish and debris unless carefully sealed.

- Bog Oak Quercus Species:

- Origin: Ancient wood, some in Europe, Ukraine, Croatia, Western Europe.

Also called Morta, Bog-wood, This is a very special wood, long

prized for its rarity, darkness, and stability. Some ancient bog oaks were

even said to possess magical powers. This is not plain contemporary

oak (below). Modern use of the term Bog Oak

may refer to many species of mineralized and buried woods, but this is not correct. True bog oak is of the oak (quercus)

species. It is wood that has fallen in a peat bog, into anaerobic

wet bog, and therefore does not decay, but is preserved for hundreds

to thousands of years. As it sits in the bog, water carries minerals

into the cellular structure of the wood, darkening and hardening it.

The longer the oak has been in the bog, the darker it becomes. This

makes a very stable and strong wood, highly resistant to decay, in

actuality, mineralized oak. A very prized and expensive wood, used

to make primarily knife handles and even sculpture and jewelry.

Important to this wood is a dating method or record of provenance;

without it, it could be just darkened oak. Many sources of bog oak

in western Europe have played out an its extraction and sale is

tightly regulated, though I've had a writer inform me that in

Western Ireland, great amounts are being "cleared out of the way

to make room for trees for telegraph (electricity) poles." If

this is true, this could be a great supply of a material that is

expensive and hard to acquire. It's also sad that this very special

material is ignored and left to rot. Once it's gone, there will be

no more...

- Bois d'arc (Osage Orange)

Maclura pomifera:

- Origin: Southwestern United States. The name "arc of

the bow" is from the wood's use as bows for Native American tribes. This

smallish tree was encouraged in Oklahoma and Texas as hedgerow, and produces

some of the hardest, toughest wood in the Americas. It's been planted more

than any other tree in America. The wood is bright, clear, straight grained

lemon yellow in color. It is hard, dense, heavy, and takes a bright glossy

polish on knife handles or other implements or tools. Care must be taken not

to overheat when working with the wood, as it darkens and burns easily.

Little change occurs on the knife handle during aging. When applied to a

knife handle, it stands alone in color and clarity; I know of no other wood

that can be confused with Osage orange. The tree bears inedible "oranges"

and the wood has an almost citrus scent when working. It's also been used

for veneers, wheels, archery bows, accents in inlay and marquetry, and for

dyes.

- Box Elder Burl

Acer negundo, F.Aceraceae:

- Origin: Northeastern United States. Box elder is a

member of the Maple family. It is a medium sized tree, and is planted often

for shade, the form of the tree has multiple branches and therefore whorls

and crotches in the wood. The wood of interest in this tree is the burl

wood, hard, twisted, knotted, with beautiful figure, whorls, and curves. It

is a favorite of mine in knife handles, original, wild, and highly figured.

The burl is often pressure treated and impregnated with dyes and either

polymer or phenolic resin (see

stabilized woods on this page) for a gorgeous and striking knife handle material. As

with all stabilized woods, it is mostly waterproof, long lasting, takes a

fine polish and finish, and is very stable.

- Buckeye Burl

Aesculus glabra or Aesculus flava:

- Origin: Central United States from Alabama to

Pennsylvania, originally imported from Germany. Most people know this tree

associated with the name "Buckeye" and Ohio, it is the state tree and the

name of college teams. Many people have seen the buckeyes, the seeds of the

tree, they are hard, dark brown, round about an inch in diameter, and

glossy. The are supposed to resemble the eye of a buck deer, hence the name.

The seeds are poisonous. The tree isn't much to look at, small to medium

sized, resembling a horse chestnut, with smelly twigs and flowers, and for

the most part the wood is soft. But the wood has rippled, wavy figures, and

the burl is magnificent when stabilized. I've used stabilized buckeye burl

for years and it makes a beautiful, serviceable knife handle. I've even got

a buckeye burl table in my home, and it has fascinating figure. The wood is

also used for paper, splints, wooden limbs, and veneers. It's even

used for coffins!

- Bubinga

Didelotia africana or Guibourtia Demeusei:

- Origin: Gabon, Camerouns. Reddish brown fairly hard

and dense exotic wood with interesting broad bands of figure, sometimes

wavy, takes a very nice polish and finishes well. Durable, resistant to

stains and doesn't darken with age. Varnishes or oils well. Makes a great

knife handle, sheath, knife case, or stand component. Used in veneers, fine

cabinetry, building small boxes.

- Cherry (Black Cherry) Prunus serotina

- Origin: Eastern North America. This is not your domestic cherry tree, nor is it the decorative cherry that is imported

from Japan and is the focus of cherry blossom festivals. This is

American Black Cherry, a staple in building fine cabinets, furniture, turnings, carvings, and musical instruments, so it's not

surprising that it's important in knife making, too. In the

domestic wood trade, it's simply called cherry. While I don't use it for handles (there are more striking woods), I do use it

in the studio in both my sole authorship and collaborative works for cases, stands, and chef's knives blocks. It's stable, predictable, and

takes a very nice finish. It's got a very fine grain, with small, tight pores, and not much figure, but this does not stop it from being one

of the most valued and dominant premier domestic hardwoods.

- Cocobolo

Dalbergia retusa:

- Origin: Pacific seaboard of Central America from

Mexico to Panama, Costa Rica, Nicaragua. This is probably the most popular

wood for fine knife handles and gun grips. It is a very dense, very oily,

very resinous hardwood. When first cut, it exhibits striking patterns of

color, rich reddish browns, tans, oranges, yellows, dark reds, and dark

browns and can be straight grained of highly figured. After a year or two in

service, it darkens considerably, sometimes to near black, but keeps some

visual interest. It's very stable. The wood gives off a rich, attractive

odor when worked, but has none when finished. This wood has a long

reputation for dependability. It's used for turnery, handles, bowling balls,

sculpture, carving, scientific instruments, boat wheels, forks and spoons,

limited veneers, and wooden jewelry. Working it is tricky, as the dust can

induce a reaction similar to poison ivy. I know of one knifemaker who can

never be exposed to the dust again, because of a severe reaction. I've used

it for years, but take full safety precautions. This has nothing to do with

the final use, though, as once it's finished, it's completely stable and

non-reactive. Probably the most popular material for handmade custom knife

handles.

- Courbaril (Jatoba)

Hymenaea courbaril:

- Origin: Southern Mexico through Central America and

the West Indies, Brazil, Bolivia, and Peru. This is a heavy, dense hardwood,

with reddish brown and darker brown stripes. Takes a very good polish, is

lustrous, rich, and seems to glow from within. Takes a very long time to

dry, I had a piece that took over five years to season before it quit

moving! It's difficult to work, but worth it. It makes a bright, glassy

polished finish on a knife handle. High shock resistance leads to its use in

handles, looms, wooden gear cogs, high class furniture flooring and stair

treads because of its great resistance to wear. It is interesting to note

that the tree is the source of copal, the gummy, resinous substance used to

seal boats, and in glues and adhesives. Ancient copal became fossilized,

creating the gemstone amber.

- East Indian Rosewood

Dalbergia latifolia:

- Origin: India, Southern Asia, Pakistan, Sri Lanka,

Java. A medium density wood, naturally oily and resinous, but with large

open pores that must be sealed with a sealant, or debris will accumulate,

and polishing will dig out or undercut the sanded finish. Because of this

porosity, it's more suitable to knife cases, stands, and holders than

handles, in my opinion. It's dark purple with black streaks, occasionally

light to dark brown, reasonably attractive, and fairly inexpensive. Cracks

along the grain easily. Used in guitar fingerboards sides and backs, pool

cues, fine furniture, doors, veneers, shuttles, turnery, pens, furniture.

- Ebony

Diospyros spp:

- Origin: Africa: Nigeria, Ghana, Cameroons, Zaire, Gaboon,

also Ceylon, India. A very popular exotic wood, in demand since ancient

Egyptian times. The heartwood is black, the sapwood is called "white ebony."

Straight grained, some curliness, fine, even texture, smooth, lustrous

finish. It's very stable, high in strength, and can be brightly polished.

It's been used in handmade knife handles for centuries, with dependable,

uniform results and longevity. Used in sculpture, carving, inlays, door

knobs, billiard cues, piano and organ keys, stringed instrument finger

boards, guitar backs, castanets, and for fine veneers.

- Fruitwoods:

- Origin: Domestic. Fruitwoods used in custom knife

handles can be very stable, beautiful, and long lasting. Pear wood is rosy

pink, cream background, and fine and close grained, and finishes and

polishes well. It's used on instrument quality rulers and drafting

instruments and marquetry. Pecan, which is a species

of hickory, produces fine, even grained reddish wood with brown stripes.

Some prime pieces make great knife handles, cases, and stand components.

It's used in veneers and furniture. Apple, once cured, makes very fine knife

handles, with close grain, with a reddish brown color, and is used in golf

club heads. Peach is a very hard, tight-grained hardwood that is very limited in

supply, but makes a great hardwood knife handle. There are other fruitwoods and nut woods that are suitable for

fine custom knife handles.

- Goncalo Alves

Astronium fraxinifolium:

- Origin: Brazil, Paraguay, Uruguay. This is a very nice

hardwood, with striking patterns in medium golden reddish brown to dark

brown streaks and waves. It finishes well, is very hard and heavy, and looks

great on a knife handle, taking a glassy finish. Because of the wild

figuring, it's been used for picture inlays and is also used for dampers of

grand pianos, boatbuilding, fine furniture. It has a reputation for being

one of the most beautiful exotic hardwoods.

- Guayabillo (Verdolago)

Terminalia oblonga or Terminalia Amazonica:

- Origin: Tropical forests of Central and South

America. This is a smooth, even grained and textured wood, of fairly hard

and dense. The color is red-brown, with straight figure and darker brown

growth lines. It has high impact strength, polishes well, and is very

durable. I haven't used it much for custom knife handles, but like what I

have and will continue to use it in future projects. It's also used

extensively for flooring, decks, utility poles, tool handles, furniture,

turnery, structural timber, and veneers.

- Honduran Rosewood

Dalbergia stevensonii:

- Origin: British Honduras, Brazil, Belize. This

hardwood has a long history of usage and export, it's pinkish brown with

some purple and darker and lighter bands. It's hard, heavy, oily and

resinous, and makes a superb knife handle. The color doesn't change (like

cocobolo), and it takes a very keen polish and stays that way. It makes a

great knife handle, and keeps it's pattern and figure even through rough and

long term handling. It's used for the manufacture of xylophones and

marimbas, furniture, cabinets, bank fittings, paneling, carving, sculpture,

bowls. This is a very highly prized exotic wood rumored to be diminishing in

supply, but I see plenty of it on the market all the time. Makes me wonder

if this is a ploy to keep the prices high.

- Honduran Rosewood Burl

Dalbergia stevensonii:

- Origin: Same as Honduran Rosewood above. Unlike the

listing above, this wood IS very rare; I was lucky enough to come across a

burl of Honduran Rosewood years ago, and have some of it left. I've never

seen any more of it it my whole career of knife making. The burl is filled

with knots, wild circular forms and waves, there is not one straight line on

it. Most of the ringed patterns are smaller than a dime, and it's hard to

get pieces uniform enough for a knife handle, but when I can, it's worth

it. Very beautiful stuff.

- Imbuyia or Imbuya

Phoebe porosa:

- Origin: Southern Brazil. Chocolate brown to

olive-yellow, and may be variegated, fine textured, mostly straight grained,

but sometimes wavy. It takes a medium high polish. This is a medium weight,

medium hardness wood, and is decorative. I've had good luck with it in knife

handles, when well sealed, and it makes a beautiful case or knife stand. It

looks somewhat like walnut, but with more figure, and is used for cabinets,

furniture, joinery, sculpture, turning, rifle butts and gun stocks. Some

veneers are made from it.

- Ipe

Tabebuia avellanedae:

- Origin: Tropical America. Olive-brown colored

heartwood, with yellow lapachol powder in the grain, so there are tiny

yellow lines in the finished wood. It's similar to teak in appearance.

Satiny finish. It's very dense, moderately hard, and very long wearing. The

grain is straight. It's not a common knife handle material because it's a

bit boring, with pretty much olive straight lines and bits of yellow. Good

for cases, stands and other decorative knife components. It's used for

decks, docks, fine veneer, railway ties, and work requiring high wear

resistance and resistance to decay. A very tough wood

- Ironwood (Desert)

Olneya tesota:

- Origin: Sonoran Desert, Americas. Ironwood deserves

special attention. There is a lot of confusion as the term "Ironwood" refers

to many trees in many nations. It seems that every country has some hard

wood or tough tree that deserves the name Ironwood, and there are over 80

distinct species from all over the world that are commonly named "Ironwood."

Common trees that bear the Ironwood name are: American hornbeam,

Black Ironwood, Desert Ironwood, Olive trees, Hop Hornbeam, Persian

Ironwood, Ipe, Rose Chestnut, Ceylon Ironwood, Australian Ironwood, and even

Lignum Vitae, the densest wood known. The Ironwood that knifemakers mostly

use is Desert Ironwood, that comes from the Sonoran desert in Arizona and

Mexico. It is very hard and dense, naturally oily and resinous, and takes a

very bright glassy polish. It's impervious to just about any thing, and long

wearing. The colors and patterns of Desert Ironwood can be wild and

beautiful, straight grained, or demure. Some of it has an almost chatoyant

(cat's eye) effect in the figure. In custom knives, it's probably the second

most common handle material, next to Cocobolo. Outstanding pieces with high

figure are very prized in the custom knife field. It's also used in

carvings, sculpture, and small boxes, as well as inlay, accents, and even

jewelry. There is a lot of misinformation around about how rare

it's becoming and how hard it is to find, but it's commonly for sale

everywhere, and often marked up outrageously. One only needs to go to any market in

Mexico, and you'll find hundreds of badly done carvings out of really nice

Ironwood at a very reasonable price (they slab out nicely). It's

probably enough to know that much of it is used to make charcoal,

which speaks to the volume of trees and ironwood out there.

- Kingwood

Dalbergia cearensis:

- Origin: Brazil. This fine wood is a member of the

rosewood family. It has a rich violet-purple striping to black, with cream

undertones. It has a fine texture, is uniform and mostly straight grained,

somewhat waxy, and finishes and polishes brightly. It's a very heavy, dense

wood, and moderately hard. The name is derived from its preference by French

royalty and the Georgian period of English furniture, and was the preferred

wood for thrones and royalty. I've used it extensively in fine knife

handles, and it's a great, long lasting, hard, dense glassy handle,

wonderful to touch. It's use is mostly decorative, though, because the tree

is rather small. Used in turnery, sculpture, veneers, marquetry, and to

restore that old French and English furniture. Another wood claimed to be

scarce, yet there are many sources of it.

- Lacewood Cardwellia

sublimis:

- Origin: Australia and Europe. Often called Silky-oak,

but is not an oak at all, and there seems to be confusion

between Northern Silky Oak and Southern Silky Oak; we'll deal with

the Northern Silky Oak. This is a striking wood, with a "basket weave" or

"fish scale" rayed appearance of the figure, from 1/4" down to 1/16"

lacelike patterns, though it's mostly straight grained. It is only of medium

density and light hardness. It's tan to shell pink and light brown, very

open grained, so sealing is necessary, but it makes a fine knife handle.

Long term, the grain raises somewhat, and that helps to increase the tactile

feel and grip on a knife handle. Also used in decorative boxes, marquetry,

ornamental cabinetwork, and veneers. In Australia, where it is common, it's

used as a shade tree, and the lumber for building and shuttering, wood

floors, plywood, and paneling.

- Lauan (Philippine Mahogany) Shorea negrosensis

or Shorea contorta

- Origin: The Philippine Islands. Lauan (White Lauan, Red Lauan) has been called Philippine Mahogany for decades but it is not a

mahogany at all, though the name persists. This wood is light weight but fairly strong, and open-pored so does

not make a good knife handle. I've used it before in knife stands, cases, and scabbards, because it is tough,

durable and predictable. It has a very nice color when oiled and waxed, and is dimensionally stable. It's used

also in furniture and sliced for veneers.

- Lignum Vitae

Guaiacum officinale:

- Origin: All of the central Americas, from southern

Florida to Venezuela. The name sometimes refers to three species of trees,

all called Lignum Vitae (The wood of life), whose resin was believed to cure

illnesses. The wood is greenish black, mostly straight grained, and

incredibly dense, heavy, hard, and tough. It's known as the hardest,

heaviest wood in the world. It's three times as hard as oak. Its density is

almost equal to iron, an it withstands a working pressure of 2000 psi! A

full one third of its weight is comprised of gum, so it's used in mechanical

devices such as bearings, and is resistant to most chemicals and decay. As

you can probably guess, it will outlast all other woods in knife handles,

and many manmade materials. Bearings have been made of Lignum Vitae and used

in clocks, fans, air conditioners, underwater marine equipment, and

hydroelectric plants. It's been used as thrust blocks, cable guides, wheels,

and thrust blocks for propeller shafts for ocean liners. The ornamental uses are as sculpture

and turnings. As you can imagine, it makes an almost indestructible knife

handle.

- Maccassar (Macassar) Ebony

Diospyros spp.:

- Origin: East Indies, Sri Lanka, and Ceylon. This is a colorful

ebony, sometimes streaked with yellow or yellow-brown to golden lines. Like

other ebonies, it's hard, resinous, self-sealing and waxy with a fine grain.

It makes a stunning, rich knife handle. It takes a very bright polish, and

is very durable and long lasting. Also used in musical instruments for its

good tonal properties, and carvings, sculpture, furniture, inlays, and pool

cues.

- Madagascar Rosewood

Dalbergia greveana:

- Origin: Madagascar, other islands. This is a very

dark, reddish, burgundy rosewood, which is dense and polishes well. It

maintains color well, is slightly open pored, but makes a fine knife handle.

Also used on musical instruments, furniture, and turnings.

- Maple, Rock

Acer saccharum:

- Origin: United States, northeastern. This is a very

well established hardwood, also called "Sugar Maple." There are two types of

maple, only the hard maple is used in knife handles. It is a moderately

heavy and hard wood, dense and tough, creamy white with a bit of pink, and

can be curly or wavy figured (fiddleback) or with bird's eye. The texture is

fine, even and lustrous, and it takes a high polish. Usually it is stained

chemically in the finishing process to bring out the chatoyant effect in the

wood before it is sealed. It makes a permanent, hard, tough knife handle.

It's been used extensively for skating rink and gymnasium floors, bowling

alleys, butcher blocks, musical instruments, piano actions, sporting goods,

furniture, pool balls, veneers, and the tree is the source of maple syrup.

-

Maple (Fiddleback, Curly, Bird's Eye, Wavy, Tigertail, Tiger)

Acer saccharum:

- Origin: United States, northeastern. Same in every way

to Rock (hard) Maple, but with wavy, curly, or bird's eye figure. Sometimes, specialized

treatments (usually acid washes containing iron) are used to bring out the figure. When properly

applied, these chemical agents actually react with the wood, bringing out

iridescence and deep luminosity.

What most people call

"stains" today are simply pigmented stains and dyes, and are not

the true stains of old. These types of maple make great knife handles.

see Rock Maple above.

- Mesquite (Honey Mesquite)

Prosopis glandulosa:

- Origin: Southwestern United States, Texas, New

Mexico, Arizona, Oklahoma. Also known as (go figure) Ironwood. This

is a medium density wood, takes a decent polish, but must be well sealed on

a knife handle, due to open pores. It is light reddish to pinkish brown,

sometimes with darker lines, and wavy to curly figure, and is sometimes

chatoyant when well polished, sealed and finished. Great in stands, cases,

knife sheaths, and knife components

- Mora

Morus tinctoria:

- This hardwood typically comes from Guatemala, but is native from

Mexico to Bolivia. It has a heavy figure with large stripes of dark reddish brown

contrasting with brighter stripes of golden brown. It is extremely hard and moderately heavy, taking a high,

lustrous polish. Another Mora, often confused, is Fustic, a yellow

dye-yielding tree that is actually Chlorophora tinctoria, a

different species. There is also Morus nigra (black mulberry) and

Morus lactea, from different continents, and are different trees.

Technically, the word morus is latin for mulberry, and all of these

are in the mulberry family. It's used in turnery, pool queues, and fine bowls.

Photos coming soon!

- Oak (American Red Oak)

Quercus rubra:

- Origin: Though there are over 60 species of oak that

grow just in the United States, probably the most common oak used is red

oak. I've even got a tree of this in my yard, and it's beautiful in the

fall, with the leaves turning dark red. The wood of red oak is almost common

in the U.S., but as a general building timber it is expensive. I don't use

it in knife handles, it's too large grained and porus and needs a lot of

sealing, but I use it extensively in stands, boxes, cases and components,

mostly as base and foundation parts. It takes staining well, carves fairly

good, and is a moderately strong, dense wood. It's also used in furniture,

flooring, and joinery.

- Olive

Olea europea or Olea hochstetteri:

- Origin: The Mediterranean, Kenya, Tanzania, Uganda.

Also called Olivewood, the small, twisted olive tree produces some fine

curly figured hardwood for knife handles. it is pale brown with attractive

figure in darker streaks, the texture fine and even. It's very hard and

dense and takes a fine polish, and is very resistant to abrasion. Its figure

makes it very attractive for fine knife handles. It's also been used for

furniture, cabinets, bowls, sculpture, carving, and veneers. If

properly finished, it is smooth and silky to the hand.

- Padauk

Pterocarpus dalbergioides:

- Origin: Central and West Africa. The finest type

(Andaman) from the Bay of Bengal is harvested by convict labor. This is a

commonly used exotic wood of medium hardness and density, it's only

drawbacks being the large open pores that require filling or sealing, or

they will hold debris on a knife handle. It's a wood that when first cut is

bright orange-red, then darkens some with aging and oxidation, sometimes to

dark purple. Its grain is very straight and it wears well. I rarely use it

on knife handles, because of the sealing required, but it works well as an

accent material and on stands and boxes. It does darken with oxidation,

handling, and time. It's also used on cabinets, fine furniture, fancy

turnery, in wooden levels, sculpture, and boat building. Its abrasive

resistance make it usable for flooring.

- Palm, Black

Borassus flabellifer

- Origin: Myanmar, India, and

southeast Asia. This wood is interesting because of its striking

pattern. One of over 1200 palm species, this is the one wood that is

of interest in general carpentry and fine ornament. It is of medium

hardness, and takes a bright, glossy, hard finish. In the sunlight,

the dark streaks glisten with orange translucency. Tight grained and

stable, this is a beautiful wood. Good for small projects, like

pens, bowls, jewelry, and knife handles

- Pau Ferro (Tropical South America)

Machaerium Scleroxylon:

- Origin: Guyana, Brazil, Tropical South America. Not

to be confused with Palo Fierro which is the desert Ironwood listed above.

This is a hard, dense wood with a orange-brown striping, medium density and

hardness, and takes a fine finish and polish. Often substituted for

Brazilian Rosewood. Makes a very nice knife handle. It's also used in

making musical instruments, carving, sculpture. A similar hardwood, not as

dense and with different appearance is below.

- Pau Ferro (African)

Swartizia Madagascariensis:

- Origin: Africa: Cameroon, Nigeria, Zaire, Ivory

Coast, Congo. Not to be confused with Palo Fierro which is the desert

Ironwood listed above. This is a dense, dark brown striped wood with some

reddish-brown highlights and some lighter areas. Its grain is coarser and

more wavy than South American Pau Ferro, and polishes well. Also a fine

knife handle material. Also used in turnings, carvings, sculpture, veneers,

furniture, and musical instruments.

- Peach

Prunus persica:

- Origin: Domestic United States, but native to China and is actually a member of the rose family.

What I'm describing is not the tropical wood called "Peachwood" which is a tropical tree in the

Caesalpinia family; what I'm describing is the wood of the small peach tree, found

domestically in

our United States. Known more for the

fruit, the peach is a tree that has some very fine wood if you can harvest enough of it for a project

or knife handle. The wood is extremely limited because the

tree is small, it frequently has trunk and bark splitting due to its cold sensitivity, and can be

susceptible to borers, leaving holes in the wood. If you can harvest it carefully though, the

wood is definitely worth the trouble. Peach tree wood is very hard and dense, and extremely durable.

It cuts, turns, and takes a polish well, has a very attractive figure and is tight-grained. Because of

limited sizes, peach wood is only available for small projects and use

of this wood is actually rare.

- Pecan

Carya illinoensis:

- Origin: Domestic United States. Great history, has

been a true American tree valued for its nuts at least 8000 years. One

source says the word "Pecan" was derived from the great Algonquin Indian

"Peccan," and another source says the word is derived from "pecane" an

Algonquin word meaning "nut so hard it takes a stone to crack" This is a

good example of the confusing amount and accuracy of information circulating

about woods. Pecan is the third most valuable hardwood in America, behind

Black Walnut and Black Cherry. Pecan is a member of the hickory family, and

as such is a very hard, dense, close grained wood. The color is tan with

reddish brown and darker brown streaks, and can be highly figured, because

straight lengths of grain are not common, due to branching in the wood. I've

used it for knife boxes, knife stands and components, and handles. It's used

for furniture, for fine flooring, veneers, carvings, turnings, and paneling,

and even used in the smoking of meats.

- Persimmon

Diospyros virginiana:

- A small amount of this wood was given to me by a

former knifemaker. He called it Chinese Beeswing Rosewood. It certainly has

a nice, small wavy design in the grain. Makes a great knife handle, with a

noticeable, bold figure and lines. After research I found that Persimmon

wood panels were used in early Chinese, Korean, and Japanese reproduction

furniture, so that is probably why he called it Chinese Beeswing Rosewood.

In sizeable amounts, the wood is rare and valuable, since the heartwood core

of the tree is very small. It's medium brown, moderately dense, and has a

unique wavy figure in the grain. It has a sharp, peppery smell when cut. It

polishes moderately well. It's been widely used for golf club woods, tough

textile shuttles, turnery, and striking tool handles. It' is highly

resistant to impact.

- Pink Ivory

Rhamnaceae:

- Origin: Mozambique, Zimbabwe, Rhodesia, Transvaal,

Natal. A "buckthorn," this wood is supposed to be the rarest wood there is.

It is certainly priced so. It is the royal wood of the Zulus, and only the

chief of the tribe and his sons can cut it. Well, those boys must be pretty

busy, because you can find the wood all over the internet. In the 1980s, it

was pretty pricey, but now, it's almost reasonable. Not a striking wood,

you're paying for the legend here more than anything. In fine custom knives,

makers tout the rarity, not the color or figure. Hard, close grained,

moderately dense, but with very little figure and a light pink in color. It

takes an excellent polish, and has been used for turnings, carvings, pens,

jewelry, pool ques, and musical instruments.

- Redheart (Campeche) (Chakte Kok)

Sickingia salvadorensis (also Sikingia tinctoria)(also Erythroxylum spp) :

- Origin: East coast of Mexico, Central America,

tropical America from southern Mexico to southern Paraguay and Brazil.

The name redheart refers to several different species

of wood, and currently, there is no absolute clear distinction

between them available in the research. They are so close, for our

knifemaking purposes, they are the same. The name Campeche was used

in older sources, probably for the state in Mexico on the Yucatan

peninsula where this wood is found. It's important to note that the

place names of woods are almost useless; there is another wood named

Campeche (Haematoxylum campechianum) that is used to produce a blue dye!

This wood is red, red, red. Sometimes has lighter shades, almost golden,

and often dark, even violet stripes. It has so much red that it is used

to produce red dye. The finish darkens on application of oils or waxes,

so don't expect the initial red color of the new knife handle to stay

bright. Strong exposure to UV light will cause flattening and

fading of the intense red, so it's best not to store it (or any

other knife!) in direct sunlight or intense lighting. It has fairly straight tight grain, finishes well and is of

medium to high hardness. Very stable, similar to teak. Takes a medium

luster, but the somewhat open grain can pick up polishing compounds and

darken unless sealed. Used also in turnery, inlay, boxes, trim, and

carvings. Finding matching colors is somewhat difficult, so it's not

used much in veneers.

- Redwood Burl

Sequoia sempervirens:

- Origin: Western United States, California. Redwood is

a fairly soft wood, so its use on knife handles is only possible when the

wood is pressure stabilized, that is injected with thousands of pounds per

square inch of polymer resin. The burl of the redwood is especially

attractive with reddish brown swirls, curls and knots, and makes a very fine

knife handle (when stabilized). Also used in turnery, bowls, carvings,

fittings, and fine furniture.

- Snakewood

Piratinera guianensis:

- Origin: South America, British Guiana, Brazil,

Venezuela, Colombia, Panama, West Indies. One of the finest woods available,

and highly prized in all its uses. All sources claim that it is highly rare

and scarce, and it's very expensive, but there are hundreds of sources. It's

extremely hard, dense, tight grained, with a spotted figure that is

distinctive and unique. Colors range from reddish brown background to dark

brown spots. It takes an extremely high glassy polish, and is naturally oily

and resinous. It makes a fantastic knife handle, very stable and long

lasting, with a unique appearance that cannot be imitated. Also used in

violin bows, fine umbrella handles, fishing poles, fine canes, veneers,

inlays, and fine furniture.

- Tamboti (African Sandalwood) Spirostachys africana

- Origin: Eastern Africa and Mozambique. This is not the traditional Australian or Indian sandalwood, which

are different species, but the rich, spicy and long-lasting aroma of this wood makes it clear why it's often called

African Sandalwood. The smell is sweeter than that of sandalwood,

and freshly cut, can scent for a long time. This is an oily, hard, colorful and dense wood, used for walking sticks, turnery,

necklaces, and furniture

and has high longevity, durability and stable appearance. It takes a rich,

lustrous shine. Though I've seen it claimed to be rare, this wood is

very available at numerous sources. On the knife handles, a

brisk rubbing brings out a hint of the rich aroma.

- Thuya Burl

Tetraclinis articualta:

- Origin: Along the Mediterranean in northern Africa, Malta, Cyprus.

Thuya burl has a long history, being mentioned in the bible and having been

used during the time of the Roman Empire.

Thuya is almost always used in burl form, which means digging out the root

ball of the tree, which is an expensive way to harvest wood indeed! Thuya

burl is worth it though, yielding dense, solid, and compact burls of wavy figured

hardwood that is strangely uniform for the convoluted banding, shapes, and forms that

appear. It is much harder than American Redwood burl and Amboyna burl which are also

frequently used as knife handles. Some sources claim it is brittle, but I have not

found this to be the case at all; it is very tough. Otherwise, it could not be used

as a veneer, and it frequently is. Also used for fine cabinetry, joinery, trinkets, pens, and veneers.

- Tulipwood

Dalbergia variabilis:

- Origin: Northeast Brazil, Bahia, Pernambuco.

Tulipwood is very distinctive, with pink-rose and sometimes yellow stripes

against a cream background. This is a very heavy, dense, and hard wood, and

takes an outstanding high glassy polish. The colors fade just a bit with

time. It's been described as strikingly beautiful, and the boards available

are small, coming from a small, twisted tree. Makes a great knife handle,

hard sheath, scabbard, case, or knife stand. It has a long history of use in

fine cabinets and furniture of the 18th century, marquetry, inlay, turnery,

keys, caskets, jewelry boxes, and musical instruments.

- Walnut: (domestic American)

Juglans nigra:

- Origin: Throughout North America. This is the wood of

the American Black Walnut tree, one of the most valuable hardwoods from

North America. It's generally unsuitable for knife handles, because it is

soft, very open grained, and can easily be damaged. It's almost uniformly

dark brown, with very little figure, but occasionally can be found in burl

and wavy grain. Once and again, a client will ask specifically for it on a

knife handle, but it is just not hard and durable enough. I use it extensively in knife stands and knife cases, though. It's

used extensively for rifle butts and stocks, high quality furniture,

turnings, plywood, veneers, clock cases, musical instruments, and wood

sculpture.

- Walnut (tropical)

Juglans australia or Juglans neotropica:

- Origin: South America, Peru, Colombia, Ecuador,

Venezuela, Mexico, Argentina. Similar to domestic American Black Walnut, but

often with some inclusions of white minerals and silicates in the grain. Not

quite as uniform as domestic walnut, all other traits similar. Like American

Walnut, I stay away from knife handle use, but use it extensively on stands,

cases, and sometimes sheaths.

- Wenge

Millettia laurentii:

- Origin: Zaire, Cameroon, Gabon. Pronounced "when-gay"

or "when-gee." This is a stunning-looking wood, with very profound light and

dark brown bands in the figure. It has high density, but medium strength,

and splits very easily, so its use on knife handles must be carefully

considered and well executed to prevent splitting. Its texture is coarse,

and the pores are open and need sealed well. It has great shock resistance.

I like using it in stands, if it doesn't detract from the knife. It's used

also in flooring, joinery, turnery, and wood sculpture, boxes, veneers and

cabinetwork.

- Zebrawood

Microberlinia brazzavillensis:

- Origin: East Africa, the Cameroons and Gabon, but

there are a whole assortments of tropical hardwoods called Zebrawood, also

in Central and South America. This is a very hard, dense wood with a medium

open grain. It's true to its name, with dark brown bands of figure running

through a light tan background. Since the grain is somewhat open, it must be

well sealed on the knife handle. The wood's appearance lasts and doesn't

fade after many years of use. Makes a stunning knife handle, not suitable

for smaller handles, as the figure is wide and may not be noticeable. This

fine wood is also used for marquetry, inlays, cabinets, furniture, turnery,

sculpture, and carvings.

- Ziricote

Cordia sebestena:

- Origin: Florida, West Indies, Central America,

Brazil, Argentina, Mexico. Ziricote is a beautiful hardwood, extremely

dense and close grained and has often bold and wild figure. It's almost

brittle, but that doesn't limit its use, as it takes a high polish and great

finish and stays that way on a knife handle. The color ranges from olive

brown, medium brown to dark almost black-brown, and often has a

"checkerboard" type of figure. It's also used on musical instruments,

carvings, fine furniture, animal calls, canes, cabinetry, carvings,

sculpture.

Note: This list was put together

with my own hours, painstakingly researching and writing each name. This I have done as a service to my tradecraft and art, and not for any

personal gain. I do this because there needs to be this resource, for all to see!

What you won't see anywhere else is the size and scope of this

list, and the links to more descriptions and photographs of these woods

used in custom and fine handmade knife projects and accessories. Also,

while publications and books will always be of value, there is one thing

that they cannot do, and that is to grow. This site, my work, and this

very list, links, descriptions, and photographs will continue to grow,

and will, simply, outgrow any published list or works. This is the

nature and scope of the internet, and I'm glad you are here!

Thanks,

Jay Fisher