Jay Fisher - Fine Custom Knives

New to the website? Start Here

"Raptor"

"The history of the sword is the history of humanity."

Sir Richard F. Burton, 1884

There is nothing in the history of man that can compare with a sword. No club, no knife, no tool, and no firearm could ever be mistaken the sword. Nothing can compare with the feeling a human has when he wraps his hand around the sure and solid grip, when he lifts the blade toward heaven, and when he pulls the blade through the shadowy ether-

It is one thing to hold a hammer, another to hold a two-foot long pipe. But when you add a sharp cutting edge to a long blade, the energy and dynamics of the entire experience changes. When you hold a real sword, you are instantly linked to our our human history, and you can feel a connection that is not available by any other means.

Most of the swords made in current times are simply not real, but replicas heralding back to an earlier time or style. While modern media entertainment offers up plenty of styles and unbelievable feats of these curios, there are few actual modern, real swords in existence.

Like my knives, with swords, I make the real thing, and one of these shown on this page has even seen combat. I use the finest modern tool steels, properly hardened and tempered, blades accurately hand-ground and hand-finished, with working-tough materials in the fittings, guards, pommels, spacers, handle materials and scabbards. Though my swords may never be asked to cut a thing, like my knives, they are fully capable, properly hardened and tempered, balanced and fitted with their matching accoutrements and accessories.

The word of God is living and active. Sharper than any double-edged sword, it penetrates even to dividing soul and spirit, joints and marrow; it judges the thoughts and attitudes of the heart.

--Hebrews 4:12

The sword has always fascinated man, and plenty of different types of swords have been created by humans throughout history. These reside in some of the most important and substantial museum and private collections, and I encourage and support the vision, passion, and determination to preserve this somewhat tenuous and delicate part of human history.

In current media, television, and on the internet, most of what you see of swords are not real. Considering the popular culture swords (pop swords), movie swords, the contribution of anime, video and computer games, fantasy comics, as well as the entertainment media and it's easy to see that the sword has evolved from an actual edged weapon to an illustrated figure of icon. There are many of these types of images, styles, and creations available as knock-offs, reproductions and novelties, but extremely few that are the real thing.

What is the real thing, particularly when compared to what is available through mass marketing media and movie-licensed outlets?

"There are a greater number of samurai swords in America today than there are in Japan."

--John M. Yumoto

The Samurai Sword, 1958

"The White Arm is more than the oldest, most universal and most varied of weapons, it is the only one that has lived through all time."

-Richard F. Burton

The Book of the Sword, 1884

If you are here because you are interested in ordering a custom handmade sword, I appreciate your interest. Making a custom sword is one of my greatest pleasures and honors in my professional life, and the patrons who commission them have my highest respect. Before you contact me about a custom sword, there are several key considerations I'll ask you to consider:

If you've considered these aspects of your project, then I'll be glad to talk to you and give you a detailed quote. Email me and we'll discuss your exciting project!

This piece was made to honor Dr. Steven Rosenberg, MD., PhD., head of oncology at the National Institutes of Health. It was commissioned by Tom Clancy, world renowned author and philanthropist. It represents slaying of the black dragon of cancer, to honor Dr. Rosenberg's work in pediatric oncology.

Hundreds of hours were invested in this piece. The sword and dragon sculpture are my own work, the casting of the lost wax sculpture in bronze was performed at Mesa Bronze Foundry in Center Point, Texas. The bronze was cast before I had an onsite foundry as I do now. The dragon weighs 400 lbs, and has a 58" wingspan. I carved the claws and feet large to represent the filaments of a cancer cell, reaching into other cells. The eyes are made of aventurine and blue tiger eye quartz.

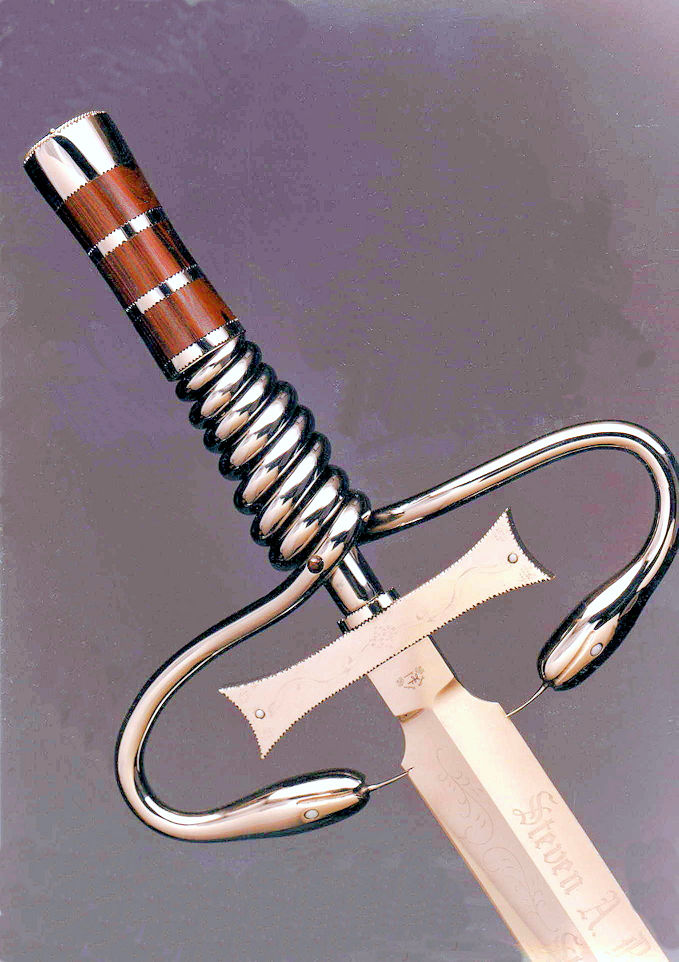

The sword represents the medical caduceus, and has a 56" blade of hardened and tempered 440c high chromium stainless tool steel, double hollow ground and mirror finished. The guard is hand-carved 304 stainless steel, 25% chromium and 8% nickel, mirror finished and hot formed into spiral snakes that wrap around the handle core. The snakes' tongues are forked and wrap around the sword's cutting edge. The snakes eyes are solid Australian opals, representing the manifestation of life. The core is banded red jasper and hematite, chosen to represent tissue. The pommel is stainless steel with silver bezels embracing a solid polished gem of blue obsidian, into which is engraved the medical caduceus.

Click on the thumbnails below for enlargements.

More pictures coming; website rebuild underway!

More pictures coming; website rebuild underway!

If you're interested in the price of an authentic, well made, real custom sword, please read the section "What do your knives cost?" on my frequently asked questions page.

"The Warrior's Quill:" Fine Custom Rapier and Parrying Dagger.

True to historic form and function, this rapier incorporates modern technology with ancient design and style. The 45" long blade is 440c high chromium stainless steel, hardened with a graduated temper. The blade is springy and flexible at the tip (Rc55) and the temper graduates to high hardness and great strength at the ricasso (Rc60). The parrying dagger was traditionally carried in the other hand, and this one has a 14" blade. The blades both have a half-length cannelure which reduces weight and increases strength by forming an "I-beam" down the center of the blade. This limits lateral flexion. The blades have third-length piercework, which has several functions. One is to reduce weight without sacrificing strength, another is decorative, and the third is a bit more sinister. In days of old, the piercework was loaded with poisons, mainly rotten meat and feces, to infect the opponent, fatally. The hilt has an active Pas d' ane, which is actually a spring force distribution device that spreads shock and energy across the ricasso, the thickest, strongest part of the blade. Most historians consider these finger rings. They are wrong. The pas d' ane also has an arrangement of transfer springs to further distribute the shock energy. All the spring steel in the hilts is hand-engraved and hot blued with nitrate salts. The handles have stress-free mounts of labradorite gemstone, cut and polished for an absolutely stunning angle of display of reflected light in blues, greens and even warm reds. The play of light in labradorite is so unique that it has it's own mineralogical term: labradoressence. The pommels are fluted, carved, engraved and blued, and both have matching labradorite gemstone cabochons mounted and polished in them. The scabbards (sheaths) are made of the exotic hardwood Arririba (Canarywood) and finely finished. The sheath fittings have matching milling and hand-engraving, and are also nitrate-blued for a deep cobalt-blue color. Both blades mount on a family Coat of Arms frame, made of antiqued oak and appliquéd lacquered and anodized carved aluminum panels. The Coat of Arms was researched to be of correct historical depiction and display.

I don't know how many total hours are in this piece, but the rapier blade alone took 80 hours to grind!

Click on the thumbnails below for more pictures of this fine piece!

If you're interested in the price of an authentic, well made, real custom sword, please read the section "What do your knives cost?" on my frequently asked questions page.

The Ultimate Warrior

Here is picture of The Ultimate Warrior, a combat sword made to use in active duty modern military combat. It's made of .250" thick 440C Stainless Steel, satin brush finished, with custom engraving on the blade. The blade is hollow ground, yet thick, and particular attention and design details were incorporated into the tip, the swage, and the point. Many angles come together at once to allow a strong thrusting point, a usable center of percussion, and a proper center of balance. There are 7 inches of rabid, rip-teeth serrations. This is a real sword meant for real military use, and feels powerful, balanced, and unyielding in the hand. It has 304 Stainless Steel fittings, and is full tang for great strength, that is one solid piece of steel from tip to pommel. The pommel is "fish-tailed" to positively lock into the hands. The two-handed handle scales are dark green Alaskan nephrite jade and black jade, the toughest gem available (most resistant to breakage). The sheath (scabbard) is double layered kydex over an aluminum welt frame, which has six point suspension. Shown in the picture is the dress leather (hand-tooled) harness, and there is also a combat grade waterproof nylon harness.

If you're interested in the price of an authentic, well made, real custom sword, please read the section "What do your knives cost?" on my frequently asked questions page.

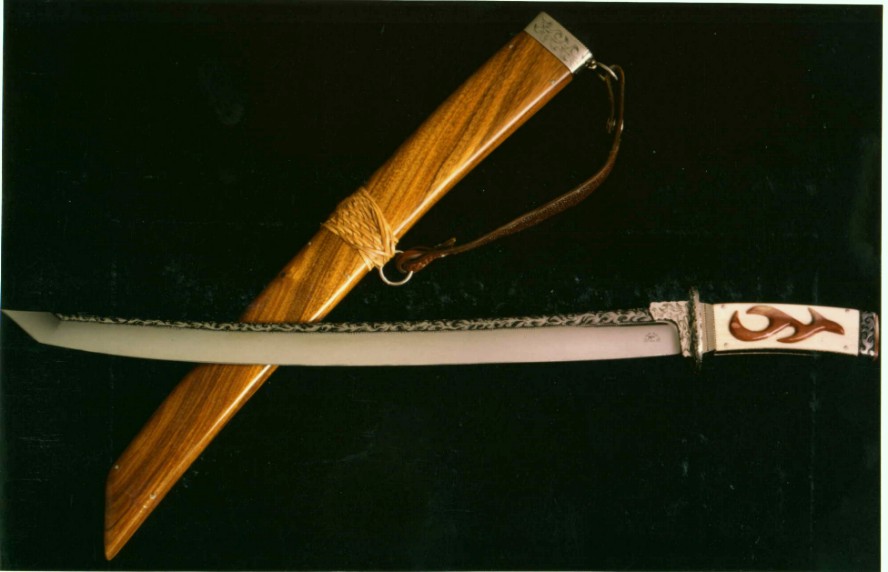

"Firewind" Wakisashi

I was inspired to make this sword after stabilizing a 16th century wakisashi for a client. This modern depiction of the wakisashi is made of hollow ground and mirror finished 440c high chromium stainless tool steel, fully fileworked and hand-engraved in a deep-relief "flame" pattern along the flats and spine. The sword has a fully engraved nickel silver habaki (ricasso frame) and pierced and engraved tsuba (guard). The handle framework is strong, hand engraved 304 stainless steel, and supports a floating (stress-free mount) overlay of prehistoric mastodon ivory inlaid with a flame pattern gemstone carving of polished Mookaite jasper gemstone. The pommel is also carved, fileworked and engraved and inlaid with a Mookaite jasper gemstone cabochon. The hard scabbard is exotic hard and polished Canarywood (Arririba), fitted with nickel silver framework hand-engraved and polished, wrapped with braided leather, and a red rayskin, hand-tooled inlayed and ringed strap. The sword feels light and fast in the hand, a formidable weapon, razor-keen.

Thumbnails: Please click to enlarge!

If you're interested in the price of an authentic, well made, real custom sword, please read the section "What do your knives cost?" on my frequently asked questions page.

Are there more swords in the works? You bet. I'll always have several that I'm working on, and I'm always interested in new orders. For details about prices, ordering, and knife making in general, please look at the FAQ page here. If you're interested in blades, check out the blades page here, and for some really stunning work, look at the Museum page here.

Please contact me for any inquiries!

Find out about how to order your custom knife, sword, or dagger here

Need more details? Jump to the FAQ Page here.

back to The Awe of the Blade

| Main | Purchase | Tactical | Specific Types | Technical | More |

| Home Page | Where's My Knife, Jay? | Current Tactical Knives for Sale | The Awe of the Blade | Knife Patterns | My Photography |

| Website Overview | Current Knives for Sale | Tactical, Combat Knife Portal | Museum Pieces | Knife Pattern Alphabetic List | Photographic Services |

| My Mission | Current Tactical Knives for Sale | All Tactical, Combat Knives | Investment, Collector's Knives | Copyright and Knives | Photographic Images |

| The Finest Knives and You | Current Chef's Knives for Sale | Counterterrorism Knives | Daggers | Knife Anatomy | |

| Featured Knives: Page One | Pre-Order Knives in Progress | Professional, Military Commemoratives | Swords | Custom Knives | |

| Featured Knives: Page Two | USAF Pararescue Knives | Folding Knives | Modern Knifemaking Technology | My Writing | |

| Featured Knives: Page Three | My Knife Prices | USAF Pararescue "PJ- Light" | Chef's Knives | Factory vs. Handmade Knives | First Novel |

| Featured Knives: Older/Early | How To Order | 27th Air Force Special Operations | Food Safety, Kitchen, Chef's Knives | Six Distinctions of Fine Knives | Second Novel |

| Email Jay Fisher | Purchase Finished Knives | Khukris: Combat, Survival, Art | Hunting Knives | Knife Styles | Knife Book |

| Contact, Locate Jay Fisher | Order Custom Knives | Serrations | Working Knives | Jay's Internet Stats | |

| FAQs | Knife Sales Policy | Grip Styles, Hand Sizing | Khukris | The 3000th Term | Videos |

| Current, Recent Works, Events | Bank Transfers | Concealed Carry and Knives | Skeletonized Knives | Best Knife Information and Learning About Knives | |

| Client's News and Info | Custom Knife Design Fee | Military Knife Care | Serrations | Cities of the Knife | Links |

| Who Is Jay Fisher? | Delivery Times | The Best Combat Locking Sheath | Knife Sheaths | Knife Maker's Marks | |

| Testimonials, Letters and Emails | My Shipping Method | Knife Stands and Cases | How to Care for Custom Knives | Site Table of Contents | |

| Top 22 Reasons to Buy | Business of Knifemaking | Tactical Knife Sheath Accessories | Handles, Bolsters, Guards | Knife Making Instruction | |

| My Knifemaking History | Professional Knife Consultant | Loops, Plates, Straps | Knife Handles: Gemstone | Larger Monitors and Knife Photos | |

| What I Do And Don't Do | Belt Loop Extenders-UBLX, EXBLX | Gemstone Alphabetic List | New Materials | ||

| CD ROM Archive | Independent Lamp Accessory-LIMA | Knife Handles: Woods | Knife Shop/Studio, Page 1 | ||

| Publications, Publicity | Universal Main Lamp Holder-HULA | Knife Handles: Horn, Bone, Ivory | Knife Shop/Studio, Page 2 | ||

| My Curriculum Vitae | Sternum Harness | Knife Handles: Manmade Materials | |||

| Funny Letters and Emails, Pg. 1 | Blades and Steels | Sharpeners, Lanyards | Knife Embellishment | ||

| Funny Letters and Emails, Pg. 2 | Blades | Bags, Cases, Duffles, Gear | |||

| Funny Letters and Emails, Pg. 3 | Knife Blade Testing | Modular Sheath Systems | |||

| Funny Letters and Emails, Pg. 4 | 440C: A Love/Hate Affair | PSD Principle Security Detail Sheaths | |||

| Funny Letters and Emails, Pg. 5 | ATS-34: Chrome/Moly Tough | ||||

| Funny Letters and Emails, Pg. 6 | D2: Wear Resistance King | ||||

| Funny Letters and Emails, Pg. 7 | O1: Oil Hardened Blued Beauty | ||||

| The Curious Case of the "Sandia" |

Elasticity, Stiffness, Stress, and Strain in Knife Blades |

||||

| The Sword, the Veil, the Legend |

Heat Treating and Cryogenic Processing of Knife Blade Steels |