Jay Fisher - Fine Custom Knives

New to the website? Start Here

"Raptor"

Beyond simple tools: fine instruments and professional works of art.

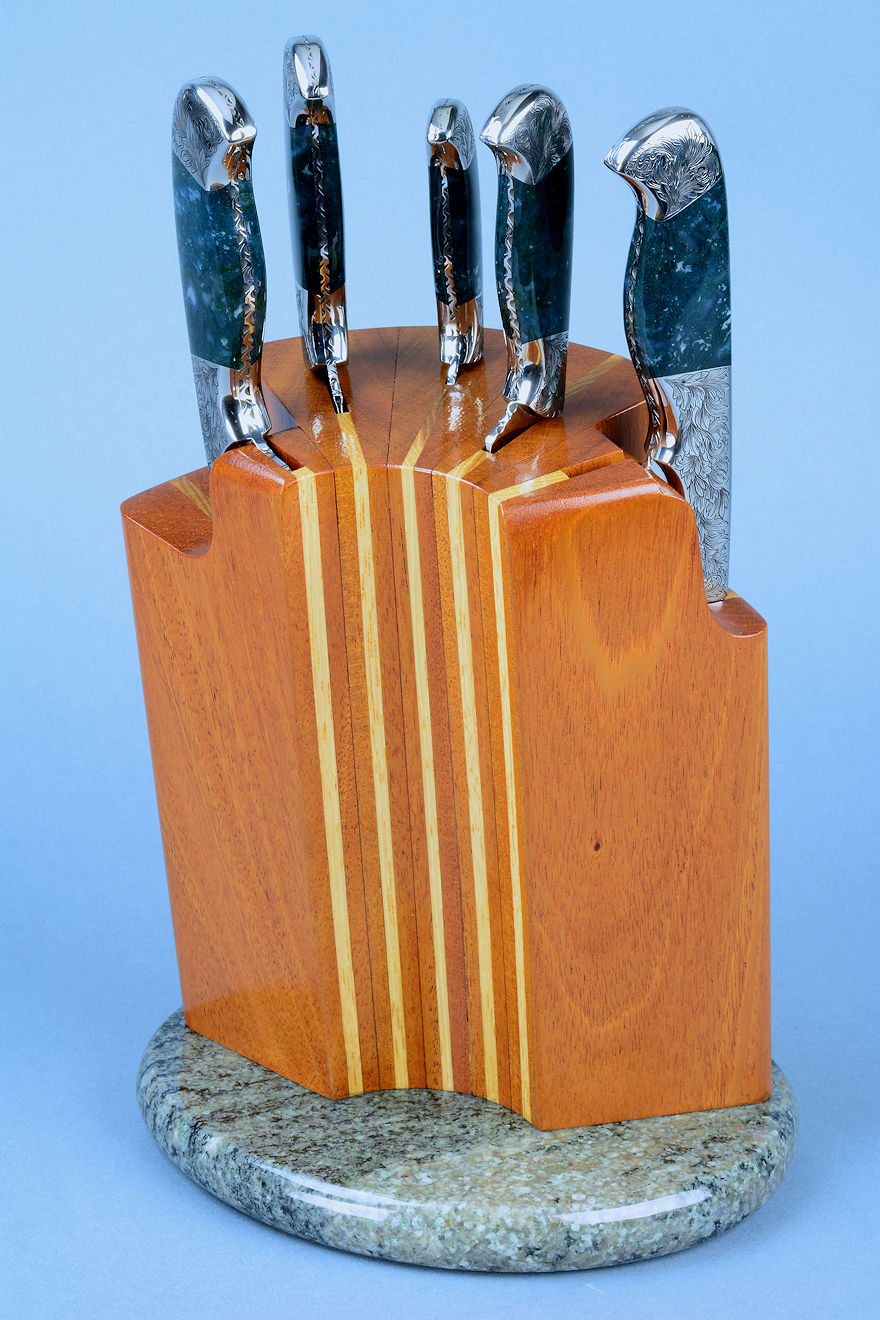

It's always a huge honor to make a legacy set for a great client, and I'm proud to present Cassiopeia. This is a fantastic custom chef's set, made of premium materials with the very best of treatments and finish, a true heritage set that will last for generations as useful, complete tools and a stunning work of art.

This is one of the very finest chef's pair of knives you will ever see, truly one of the very best ever made.

Photo above, top to bottom:

The knives are named individually for the predominant stars in the constellation Cassiopeia. They are evolutions of my previous designs, based on the needs and requirements of my client for this project.

440C high chromium hypereutectoid martensitic stainless steel is an absolutely excellent steel for the professional chef. The reason this steel excels is because it's a martensitic stainless steel, forming an incredibly strong microstructure of martensite, the acicular, hard crystalline allotrope of the best tool steels. It also can be treated to form profuse carbides: iron carbide, chromium carbide, molybdenum carbide and multi-element carbides. These intricate crystalline structures offer incredible wear resistance and high strength along with excellent toughness.

When properly heat treated, 440C is the most corrosion-resistant of all of the high alloy martensitic stainless steels, with little to no chance of corrosion, even in the acidic and corrosive environments of the kitchen. It does not form these microcrystalline components easily; it takes extremely complicated heat treatment to bring this out. While it can be conventionally heat treated, the difference between conventional processing and a highly sophisticated processing of this steel results in night and day difference in performance, durability, and ultimately, longevity. Proper heat treating is paramount, resulting in superior edge retention, toughness, strength, and corrosion resistance.

In order to bring this steel to its zenith of condition, I perform a proprietary heat treating process I've named T3. The technical aspects of this "tertiary third" formation of carbide structure is not a simple process. It takes over a week long, consists of 33 individual specific steps accomplished with high accuracy furnaces working at 1900°F, cryogenic equipment working at -320°F, and numerous staged and ramped process parameters. One small mistake will yield a less than optimum blade, and I'm determined to create the very finest knives made in the world today. Consequently, no other knifemaker, no factory, no machine shop, no heat treating facility will recreate the incredible condition of this blade steel.

For the chef that requires a tough, lightweight, and extremely fine-edged large knife, the Shedar is a supreme master chef's knife. It has a substantial heel, with a curve at the cutting edge that is just right for the board. It has a very acute, thin point, with limited lateral flexing at the tip, a prize of a knife for the skilled and accomplished chef. It's hollow ground for the greatest longevity and it's as sharp as a scalpel.

All of the knives in this set are hollow ground with a 12" diameter contact wheel. This means a long, sloping hollow grind that gives great longevity and thinness at the cutting edge, and a wide grind that can accommodate a thinner spine. More about blade geometry on my "Blades" page at this bookmark.

The Shedar is named for the bright star lying in the "queen's heart" of the constellation Cassiopeia, also known as Alpha Cassiopeiae. It's the brightest star (matching Beta Cassiopeiae) It was named in the 13th century for the Arabic root word meaning "breast," referring to the location in the constellation.

The Shedar has a large, powerful blade, truly the heart of the set. The substantial heel gives complete access to the cutting board, the front bolster has an extended length along the spine, giving a good bearing area for the thumb in a traditional grip, and a mass to hold in a controlled pinch grip. This is a large, purpose-built tool, a classic knife. The design is based on traditional French Chef's or "Sabatier" profile, and the long handle gives a great control grip with substantial bolster weight and wonderful balance and feel.

The next largest knife in the set is Caph. Caph is named for Beta Cassiopeiae, the variable star in the Cassiopeia constellation. The star varies in intensity; the knife varies in cutting edge, so it's a neat fit for the name. It's almost exactly the same length as the Shedar, and the handles are close, but there is where the similarity ends.

The Caph is a true bread knife: tough, stout, and incredibly sharp. The knife's outstanding features are my "Theatre Curtain" serrations, which, due to the ever-changing geometry, slice through hard-crusted or soft breads with ease, creating few crumbs. The blade is stiff, due to a long, tapering spine that gives good support; this is not a springy-flexible knife. Though I've included an extended front bolster to help in the geometry and offer a bearing surface for the thumb or forefinger, it's not too long so it won't interfere with cutting bread. The heel is compact and short, giving the hand some good protection from the keen edges. The tip has a broad, flat point that is strong enough for piercing without yielding.

The next knife in this great set is the Tsih. The name comes from the Gamma Cassiopeiae star in the system, and is the Chinese name for "the whip." Pretty fitting for a long, slender slicer like the Tsih, I think. This is a classic, fine shape of knife, with a sleek, thin form and elegant lines.

The Tsih is commonly called a slicing knife, made for thin slices of meat: roast, turkey, breast, etc., but is also just right for boning, cutting large vegetables, trimming, and even filleting. I didn't give this blade a lot of flexibility; I wanted it stiff, since a variety of chores are well-suited to the thin, lightweight blade. The handle is a three-fingered (or four for a slender hand) affair, balancing the blade well, keeping the easy and manageable character. The front bolster will allow full cutting edge use and penetration, and the slight heel keeps the hand safe and well in place in use.

The Segin is the next useful tool in the set. It's named for Epsilon Cassiopeiae in the Cassiopeia constellation, and the name is actually from an uncertain origin. No matter; this will be a familiar knife in the set, perhaps the most reached for and most used knife of them all! Why? Because it's an all around utility knife, of medium size, with a substantial blade that will handle most cutting tasks. The blade can be described as a smaller, shorter version of the Master Chef's Sabatier style, with a significant heel for board work, and a useful curve of the edge for dicing and mincing.

The point of the Segin is tough, supported by a wide blade, and a significant spine that means no flexibility in the blade whatever. This means that piercing is an excellent use of this point, and it handles tough fruits, nuts, and partially-frozen meats with ease. The wide, deep hollow grind creates an extremely sharp, tough edge, and the compact front bolster won't interfere with the working end of the knife. The knife feels great in a traditional, conventional grip style, or with the forefinger along the spine for guidance. The heel keeps the hand away from the business end of the keen edge, and the rear bolster balances the knife overall.

The final knife in the set is the Achird which is actually a binary star in the Cassiopeia system, designated Eta Cassiopeiae. This is the smallest of the group, but another tremendously useful and necessary knife for the chef's set. The Achird is a classic paring knife design, but it is no delicate player. I made this knife very stiff, there is no give or movement of the stout blade, offering great accuracy when the forefinger is laid along the spine for the most accurate of trimming.

The Achird knife has a tremendously useful design, for piercing, for close work, for flourishes, boning, disjointing, and working in tight areas, as well as for paring. More than any other knife of the group, this knife works like a true extension of the finger, getting into tiny spaces like no other blade design can. The photos above are enlargements; be sure and check out the actual sizes of all of the knives in the specifications below.

All of the knives are embellished with Acanthus leaves, as requested by my client. This was quite a bit of work, since all bolsters are 304 stainless steel. 304 is also known as 18-8 stainless, due to 18 percent chromium and 8 percent nickel in the alloy. It's an austenitic stainless steel that is used to make stainless nuts, bolts, and fasteners and is extremely tough. This is absolutely zero-care stainless steel, and, like the blade is completely Food Contact Safe. The bolsters are sealed in contact with the tang, and all surfaces are contoured, rounded, polished, and finished for a wonderful feel. They are attached with multiple zero-clearance peened pins for permanence; they will never, ever yield. They are dovetailed to bed the gemstone handle scales.

I chose a light, airy acanthus design, one that will be easy to manage and clean if necessary, usually with a light soapy water and a good rinse. All of the front bolster faces, whether complex extended bolsters—like the Shedar and Caph, or the rounded faces—like the Segin, Tsih, and Achird are all rounded, smoothed, contoured, and polished for easy cleaning. My client requested full filework for distinctive handmade flair, and I chose a simple vine design that is easily cleaned with a brush.

Incidentally, I recommend brushes only for cleaning all knives in soapy water; never, ever use a cloth or sponge. These knives are so incredibly sharp, they can slice right through these and into a hand! A brush is always the safest cleaning tool.

My client requested a bold, strong, green gemstone handle material. This is Green Moss Agate from India, one of the hardest, toughest, and most beautiful of all agates found. Every single piece is distinctive and unique, with rich, deep green mossy forms floating in clear, translucent, and white agate areas throughout. This is a stone that cannot be adequately described; the more you examine it, the more astounding it is. The photo above is a four power enlargement, and the detail just keeps coming!

In the 4x enlargement above, you can see a crystal pocket in the agate, along with meandering rivers of banding and speckled highlights. This is a true chalcedony, a cryptocrystalline silicon dioxide, and the impurities create the colors we see in the gem. It has a high hardness of 7 on the Mohs scale, which is very hard indeed, and there is little that can ever wear, scar, or cut this stone. This is a true eternal material; uncounted generations from now, it will still look the same; such is the grandeur of gemstone.

Some mineralogists believe that these agates form from silica gel, and the impurities are carried in by absorption of mineral salts. Some scientists believe that agates are formed by deposition, water carrying in the minerals over many millions of years. Even after man's use and love of agates for millennia, there are still mysteries as to how they came to be.

One thing is certain: man may grow artificial gemstones including diamonds, rubies, and sapphires, but he cannot grow one piece of agate: it must be mined from the earth. This is one of the reasons I love gemstone handles; you can touch them, hold them, admire them, and use them for lifetimes, and they will never change.

One of the great things about agate is that it is zero care, and is highly dense and solid. It's impervious, it's easy to clean, and I've polished the handles all incredibly smooth and glassy. The fit between the blade tangs and fittings is seamless, all of these knives are a pleasure to hold and use.

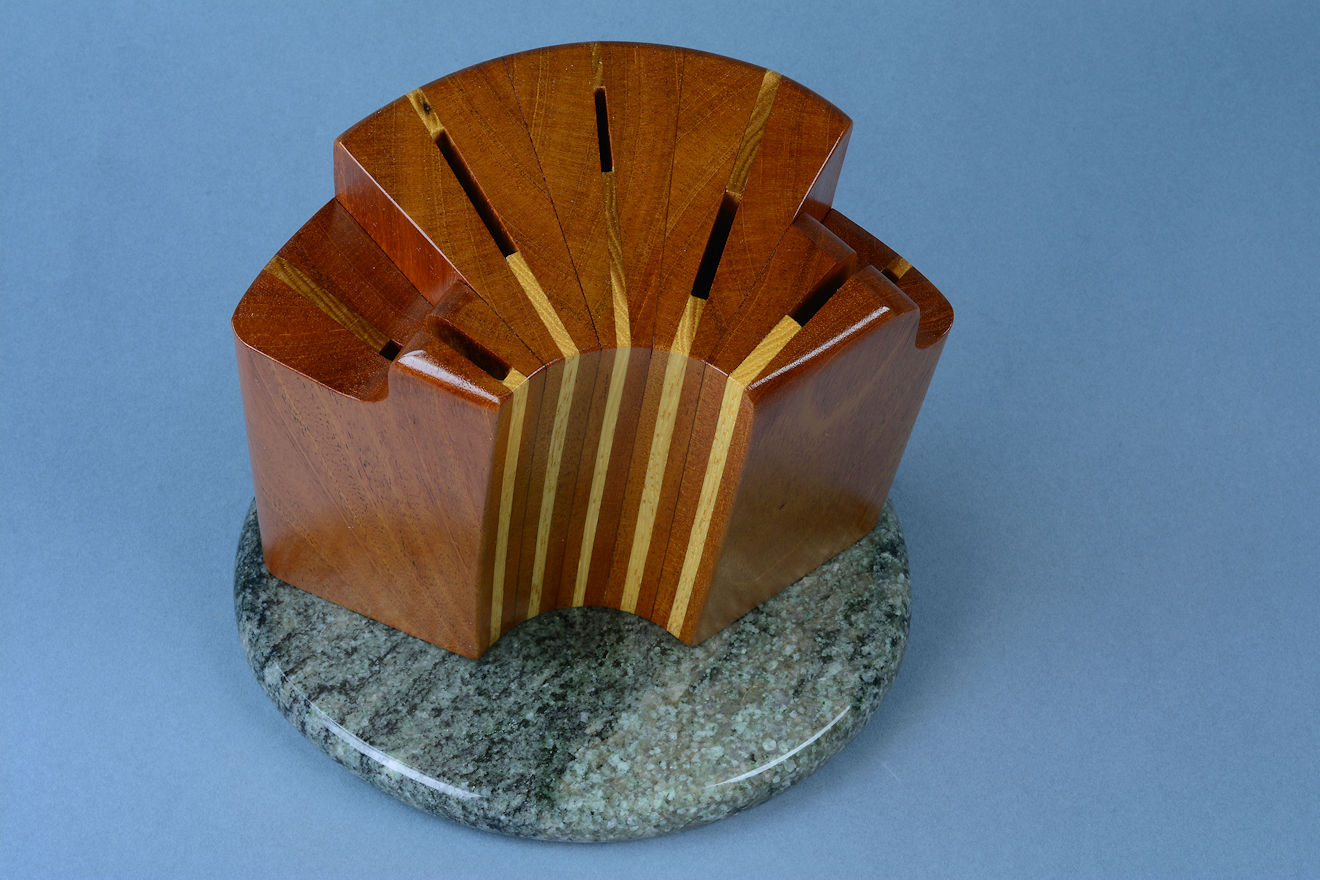

My client requested a block that was as compact as possible, and of course, it had to be complimentary to the entire set. I created it with longevity in mind and unique designs I'm known for and love to create.

I started with the idea that the knives should be protected, that the protection of the chef is first and foremost. That means a strong, durable, secure block that protects the hand from the scalpel-sharp cutting edges.

I created the block with some great hardwoods; woods that will last for centuries with little care. The main segments are Vinhático hardwood. Technically, the species is Plathymenia reticulata and it's in the family of Leguminosae. This means it's a "bean" tree, bearing seeds in long pods. It goes by many names—Brazilian mahogany, amarello, candela, yellow wood, gold wood, vinhatico castanho, tatare, and jaruma. It grows in Brazil, Argentina, and Colombia and is a big tree, growing up to 125' with a three foot diameter. The wood is highly durable, used in cabinetmaking, ship and boat building and even for dugout canoes, attesting to its water resistance.

The lighter-colored wood I used for the knife blade spacers is Pecan hardwood, from the United States. Pecan is known for its fruit (I have a Pecan tree in my yard that bears many bushels of pecans every year), and is one of the main agricultural food-trees in my state (New Mexico). The wood of the pecan is incredibly hard, tough, and strong, with excellent strength, since it's closely related to hickory. This is why it's used in baseball bats and archery equipment, as well as tough tool handles. It will never, ever wear away or degrade in this application, and the light contrast produces the look I wanted in the piece.

I created a radial design, so that the handles would be accessible and as close as possible, yet allowing the knives easy extraction from the block, with no cutting edges exposed. The size of the block was determined by the two largest blades in the set, and I placed them at the block ends. This required carved sockets to accommodate the extended front bolsters of the Shedar and Caph, while the smaller knives rest in the center. The hardwoods are sealed with Tung oil and resins, and coated with a clear lacquer for easy cleaning. The blades are not tight in the slips, they move in and out with ease.

The block is angled so that the knives have as little height as possible, yet are easily extracted without reaching high above the block. The block is screwed solidly with stainless steel screws to the granite base.

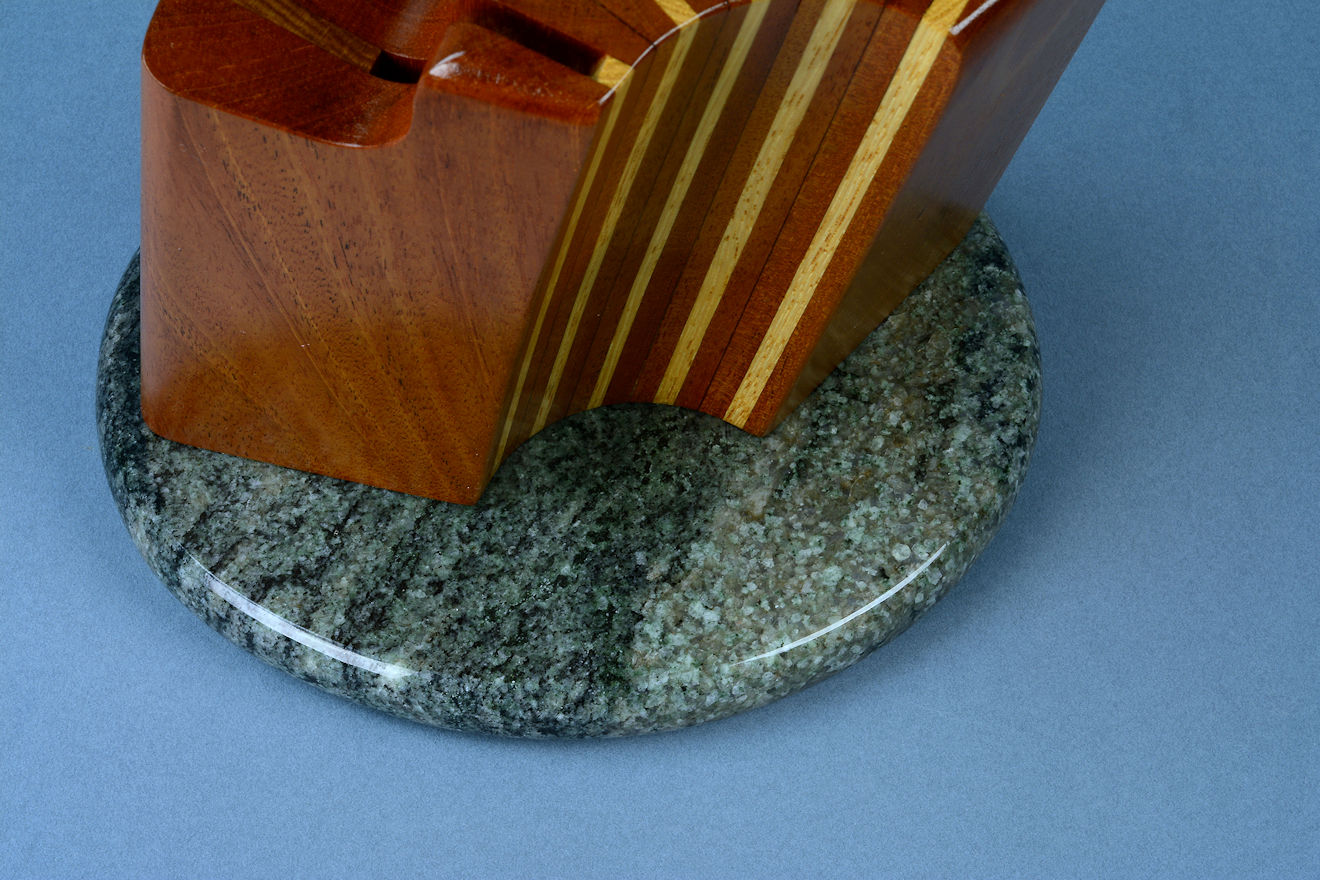

The base I chose for the Cassiopeia is Verde Maritaca Granite from Brazil. Verde Maritaca granite is actually a greenish-grey granite of the Precambrian period. It's a beautiful fit for the piece, echoing the multi-hued greens in the gemstone handles, and I created a tight oval shape, hand-finished the edges and top to a smooth, even polish that reflects the rounding of the handles. This is a zero-care granite, tough and durable, and as with all of the piece, the colors are completely natural and eternal.

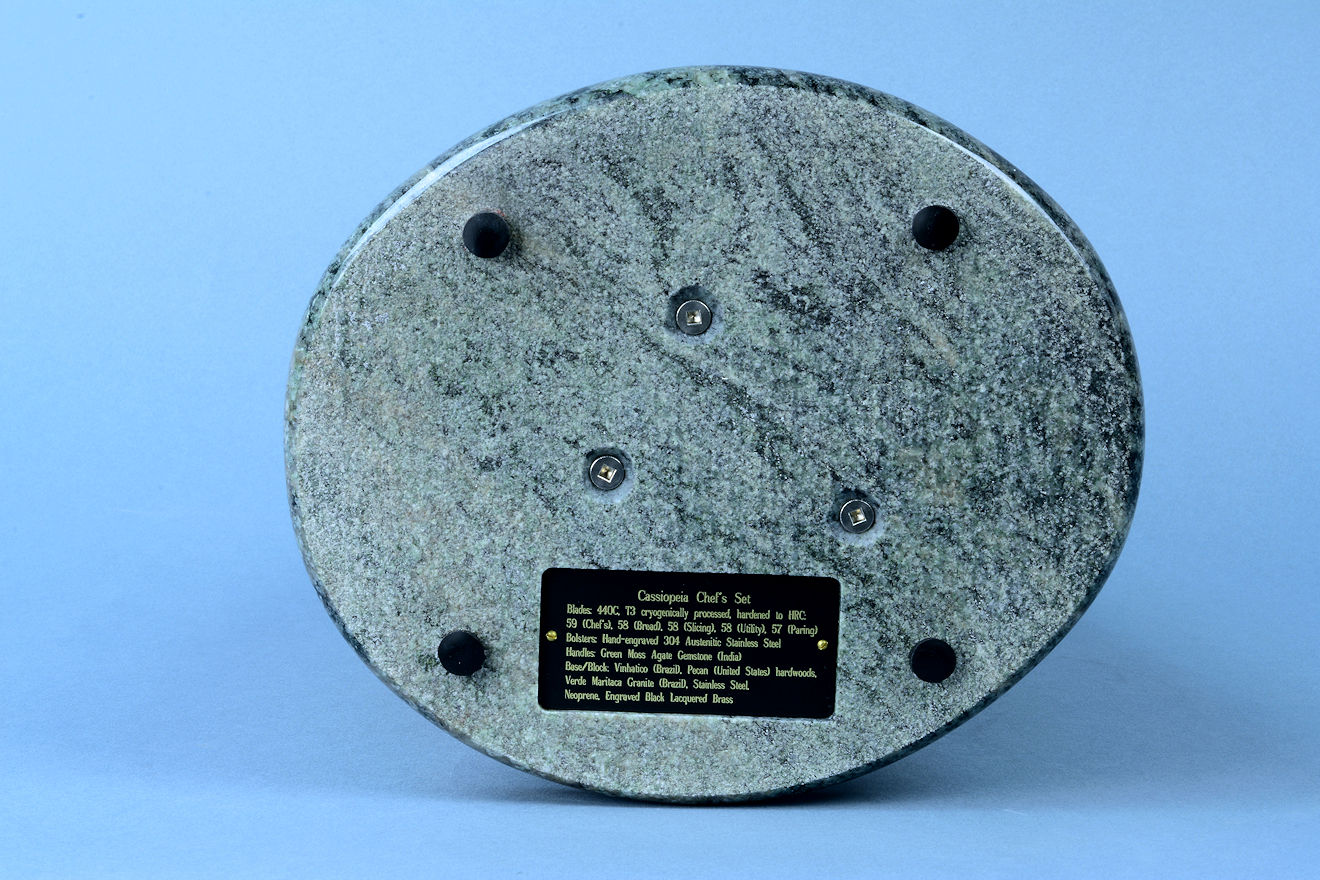

A piece is only as stable as its foundation. In the granite base, I inserted neoprene feet to protect any countertop from abrasion, and to allow air to circulate underneath for cleanliness. I used all 304 stainless steel screws to attach the block set in countersunk holes in the granite. Also I cut a milled-out pocket in the base, and inset a legend plate, in engraved black lacquered brass. The plate is protected by being inlayed, and is sealed with acrylic for longevity. The base is extremely stable and compact, finishing the piece as it deserves.

This is a magnificent set of custom knives; it was a great honor to make it for my client. Please look over the specifications and details as well as additional photographs below.

Thanks, T. D.!

Thanks, T. D.!

Hi Jay,

The knives and block arrived today after languishing in Customs for nearly a week. Must say I’m delighted with them.

Exquisitely functional tools they may be but for now I’m treating them as artworks and just admiring and fondling them.

Thanks again Jay, they are truly beautiful and the knife stand is the perfect complement. Well done, sir.

--T.

| Main | Purchase | Tactical | Specific Types | Technical | More |

| Home Page | Where's My Knife, Jay? | Current Tactical Knives for Sale | The Awe of the Blade | Knife Patterns | My Photography |

| Website Overview | Current Knives for Sale | Tactical, Combat Knife Portal | Museum Pieces | Knife Pattern Alphabetic List | Photographic Services |

| My Mission | Current Tactical Knives for Sale | All Tactical, Combat Knives | Investment, Collector's Knives | Copyright and Knives | Photographic Images |

| The Finest Knives and You | Current Chef's Knives for Sale | Counterterrorism Knives | Daggers | Knife Anatomy | |

| Featured Knives: Page One | Pre-Order Knives in Progress | Professional, Military Commemoratives | Swords | Custom Knives | |

| Featured Knives: Page Two | USAF Pararescue Knives | Folding Knives | Modern Knifemaking Technology | My Writing | |

| Featured Knives: Page Three | My Knife Prices | USAF Pararescue "PJ- Light" | Chef's Knives | Factory vs. Handmade Knives | First Novel |

| Featured Knives: Older/Early | How To Order | 27th Air Force Special Operations | Food Safety, Kitchen, Chef's Knives | Six Distinctions of Fine Knives | Second Novel |

| Email Jay Fisher | Purchase Finished Knives | Khukris: Combat, Survival, Art | Hunting Knives | Knife Styles | Knife Book |

| Contact, Locate Jay Fisher | Order Custom Knives | Serrations | Working Knives | Jay's Internet Stats | |

| FAQs | Knife Sales Policy | Grip Styles, Hand Sizing | Khukris | The 3000th Term | Videos |

| Current, Recent Works, Events | Bank Transfers | Concealed Carry and Knives | Skeletonized Knives | Best Knife Information and Learning About Knives | |

| Client's News and Info | Custom Knife Design Fee | Military Knife Care | Serrations | Cities of the Knife | Links |

| Who Is Jay Fisher? | Delivery Times | The Best Combat Locking Sheath | Knife Sheaths | Knife Maker's Marks | |

| Testimonials, Letters and Emails | My Shipping Method | Knife Stands and Cases | How to Care for Custom Knives | Site Table of Contents | |

| Top 22 Reasons to Buy | Business of Knifemaking | Tactical Knife Sheath Accessories | Handles, Bolsters, Guards | Knife Making Instruction | |

| My Knifemaking History | Professional Knife Consultant | Loops, Plates, Straps | Knife Handles: Gemstone | Larger Monitors and Knife Photos | |

| What I Do And Don't Do | Belt Loop Extenders-UBLX, EXBLX | Gemstone Alphabetic List | New Materials | ||

| CD ROM Archive | Independent Lamp Accessory-LIMA | Knife Handles: Woods | Knife Shop/Studio, Page 1 | ||

| Publications, Publicity | Universal Main Lamp Holder-HULA | Knife Handles: Horn, Bone, Ivory | Knife Shop/Studio, Page 2 | ||

| My Curriculum Vitae | Sternum Harness | Knife Handles: Manmade Materials | |||

| Funny Letters and Emails, Pg. 1 | Blades and Steels | Sharpeners, Lanyards | Knife Embellishment | ||

| Funny Letters and Emails, Pg. 2 | Blades | Bags, Cases, Duffles, Gear | |||

| Funny Letters and Emails, Pg. 3 | Knife Blade Testing | Modular Sheath Systems | |||

| Funny Letters and Emails, Pg. 4 | 440C: A Love/Hate Affair | PSD Principle Security Detail Sheaths | |||

| Funny Letters and Emails, Pg. 5 | ATS-34: Chrome/Moly Tough | ||||

| Funny Letters and Emails, Pg. 6 | D2: Wear Resistance King | ||||

| Funny Letters and Emails, Pg. 7 | O1: Oil Hardened Blued Beauty | ||||

| The Curious Case of the "Sandia" |

Elasticity, Stiffness, Stress, and Strain in Knife Blades |

||||

| The Sword, the Veil, the Legend |

Heat Treating and Cryogenic Processing of Knife Blade Steels |