Jay Fisher - Fine Custom Knives

New to the website? Start Here

"Raptor"

Beyond simple tools: fine instruments and professional works of art.

Many chefs request a reasonably-sized knife, a knife that is comfortable in the mid-range of size. A knife in that scope is capable of most of the straightforward tasks in the kitchen, without a lot of bulk and mass. A manageable size means light and speedy action, less strain, and a higher degree of control. Without a massive blade, more aggressive work could be accomplished with sturdy, effective and valuable serrations, so less force can apply clean cuts through tenacious foodstuffs. Additionally, if a set were matched, bonded by design and materials, a simple pair of fine knives could present an artistic appeal to the aspect of cutting. This was my direction for the Clarau Magnum and Kineau Magnum chef's pair.

440C high chromium hypereutectoid martensitic stainless steel is an absolutely excellent steel for the professional chef. The reason this steel excels is because it's a martensitic stainless steel, forming an incredibly strong microstructure of martensite, the acicular, hard crystalline allotrope of the best tool steels. It also can be treated to form profuse carbides: iron carbide, chromium carbide, molybdenum carbide and multi-element carbides. These small crystalline structures offer incredible wear resistance and high strength along with excellent toughness. When properly heat treated, 440C is the most corrosion-resistant of all of the high alloy martensitic stainless steels, with little to no chance of corrosion, even in acidic and corrosive environments of the kitchen. It does not form these components easily, it takes extremely complicated heat treatment to bring this out. While it can be conventionally heat treated, the difference between a highly sophisticated processing of this steel and conventional processing is night and day in performance and durability

In order to bring this steel to its zenith of condition, I perform a proprietary heat treating process I call "T3." The technical aspects of this "tertiary third" formation of carbide structure is not a simple process. It takes over a week long, consists of 33 individual specific steps accomplished with high accuracy furnaces working at 2000°F, cryogenic equipment working at -320°F, and numerous staged and ramped process parameters. One small mistake will yield a less than optimum blade, and I'm determined to create the very finest knives made in the world today. Consequently, no other knifemaker, no factory, no machine shop, no heat treating facility will recreate the incredible condition of this blade steel. Tempered to HRC 57, the result is an extremely tough and fracture-resistant knife blade, a blade that seldom needs any sharpening, and will literally last for generations.

The Clarau Magnum knife is an evolution of my original Clarau design. The name Clarau in Welsh means "claws" and that might be a simplistic way to describe the long, tapered and swept blade shape of this knife design. The Magnum designation is an increase of the size and blade-to-handle relationship in balance from a previous version of the design which was named simply "Clarau."

The blade has a substantial spine; it's not a thin and flimsy blade, but rather a stiff and incredibly sharp instrument. I made it with a deep hollow grind for a razor-keen edge and incredible longevity that only a hollow grind can offer. The combination, the blade geometry, the handle shape, the weight and size: these meld into a knife that is a pleasure to hold and use. I incorporated an accurate, beautiful vine filework completely around the spine and handle to add handmade distinction and improve traction over a smooth blade. The blade length is just right for most kitchen tasks, more manageable than a large Sabatier, light enough for boning and trimming, and still large enough for most cuts of meat and vegetables. The point is narrow but firm, for the most controlled of operations from the choil to the very tip.

The balance and relationship of the blade to handle is optimized for control. The handle is large and substantial enough for a comfortable grip, yet straight and conservatively-formed for a variety of grip styles and hand sizes. Instead of a lot of unconventional curves, depressions, and grooves, the handle is aligned clearly with the blade, offering a deep forefinger placement and protection from the cutting edge with a wide, full-coverage front bolster. The rear bolster is simply rounded and smoothed, so the knife is incredibly comfortable in the palm of the hand. The hand can be moved forward into a pinch grip on the wide bolster for more delicate control, or pulled full back for a secure grip and greater force application.

The Clarau Magnum has a smooth, scalpel-like cutting edge, and because it doesn't have the weight and mass of a larger Sabatier-style knife, more difficult cutting challenges must be addressed. For this, I created the Kineau Magnum, sister to the Clarau Magnum. Like the Clarau Magnum, the Magnum designation represents an increased size and necessary improvement of the blade-handle relationship over the original Kineau design. Kineau is my own word; it has no meaning in any language. I chose it simply because it fit the knife design and paired well with Clarau.

Back to the difficult cutting. When encountering tough rinds, skins, and tenacious materials, nothing performs like well-designed and executed serrations. This is the reason my counterterrorism knives have them; it's well known that some materials are very difficult to cut. The Kineau is designed just for these tasks, and incredible cutting chores can be made easy by the aggressive serration profile of the blade. The blade also has some recurve and an upswept arch, so penetration of the edge is always in an advancing, changing angle. Rather than a "ratcheting" type of serration, this type is smooth and sure. The Kineau blade is very stiff and stout, with no flexibility whatever, so the edge won't shy away from the work. Rather than a thin, weak point on the blade, I created it with a tiny, strong chisel, so piercing is unwavering and point strength is preserved.

The serration detail above is clear, crisp, and concise. Yet the blade is hollow ground and strong. This is a careful balance of steel type, treatment regime, hollow ground geometry, final thickness, and serration size and angle. There is no simple calculation to yield this arrangement; this is achieved through decades of practice and application. For any cutting chores that the finely-edged Clarau cannot do, the Kineau is up to the task.

While the handles of the Clarau and Kineau Magnum seem simple and straightforward, the execution is much more detailed and refined. The front bolster is full coverage, so that the forefinger encounters a wide breadth for comfort of the index finger. There is little ricasso at all, since a ricasso has no function on a knife but to serve as a transition between the handle and the cutting edge. The bolsters are zero-care 304 austenitic high nickel, high chromium stainless steel, the same steel used in all Food Contact Safe equipment approved in our country. Incidentally, the entire knife is Food Contact Safe, from the steel type and treatment to the sealed and secured handle. The bolsters are dovetailed, mounted with zero-clearance peened pins to the tang, sealed and solid. The dovetails secure the bedded complex handle scales in a doublet gemstone of Petrified (or Fossilized) Fern Jasper and British Colombian Nephrite Jade.

In the magnification above, you can see the incredible details of the gemstone handle of the Clarau Magnum. This is the vascular tissue of a fossilized (or petrified) fern, from the late Paleozoic era. The exact species cannot be determined, but the world 300 million years ago was quite different than today. Though they were the size of trees, ferns are not like trees with a central core of heartwood surrounded by sapwood. Instead, their vascular areas are full of parenchyma cells, fibers, tracheids and vessel elements. This can appear like a knotted confusion of fibers, and it is no better represented than in the fossil above. The stone is a opaque jasper, a tough, hard cryptocrystalline quartz, with tans, browns and bits of red delineating these fascinating elements.

The Petrified, Fossilized Fern Jasper gemstone is a doublet mount, paired with a brilliant layer of British Colombian Nephrite Jade. My goal was to relate the two knives, sisters in form, function, materials and use, throughout. I chose a contrasting, yet complimentary jade to represent the forest color that might have been 300 million years ago when the fern was alive. I created a very thin liner of jade, bonded and bedded to the Fossilized Fern Jasper, to accent the knife along the tang. This is called a doublet gemstone setting.

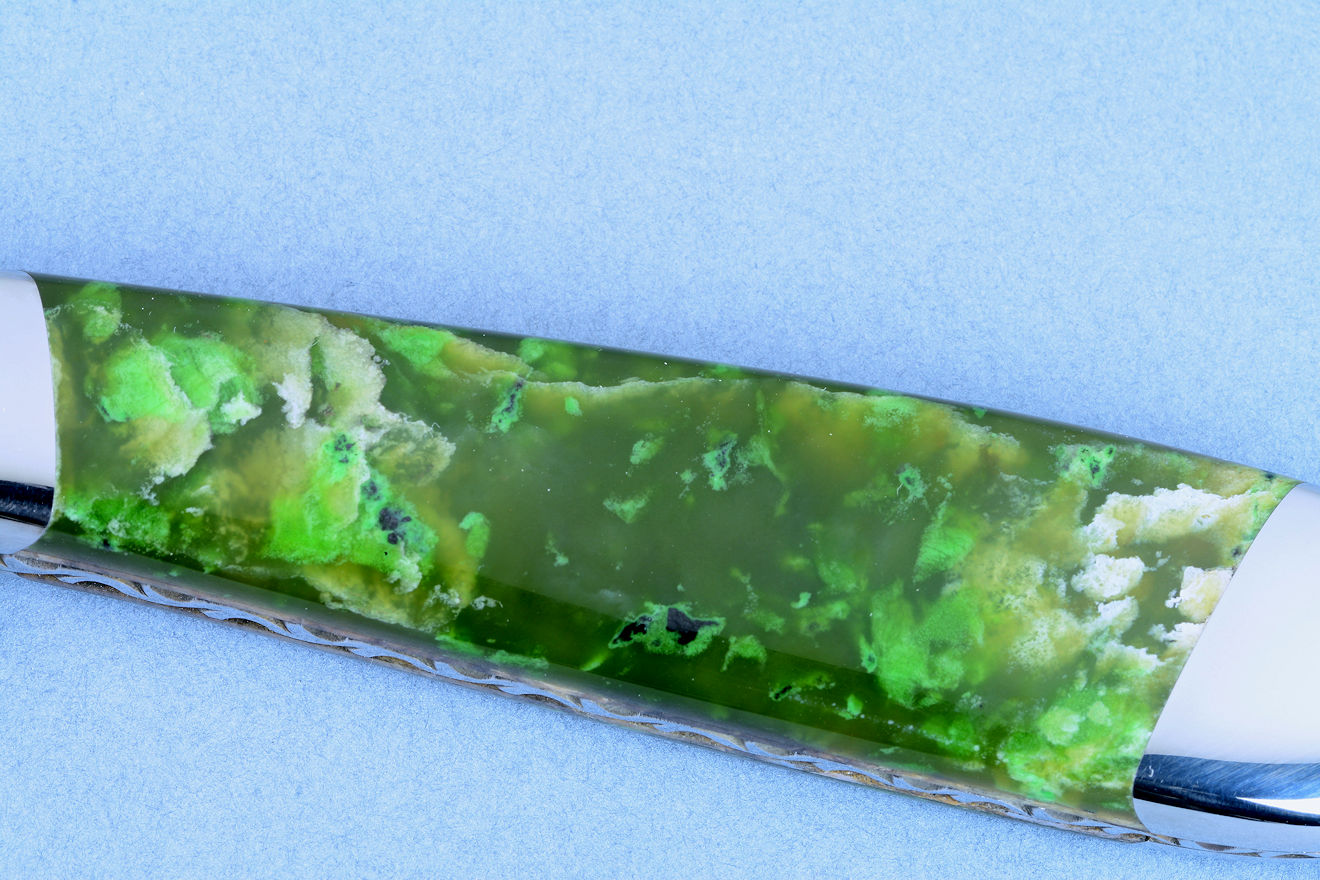

Like the doublet on the Clarau Magnum, the Kineau Magnum displays the opposite: the predominant British Colombian Jade gemstone with a light, thin accent of Fossilized Fern Jasper against the tang. The filework has a little more curvature in the design, just like the more substantial curvature of the blade, to balance the set. The Nephrite Jade is extremely tough and durable, one of the most fracture-resistant gemstones available on earth. I chose bright, patterned selections for the scales, exhibiting the boldness of the Kineau overall. The gemstone is polished to a bright, vitreous finish.

In the magnification above, you can enjoy the fantastic color and play of light that inspires me to make more gemstone-handled knives than any knifemaker in history. Nothing in man's inventory of his own creations can approach the natural color, intensity, and figure of gemstone. A sea of green clouds, a cloudy green sea, the outburst of a distant nebula: what do you see here? The application was just right, the fit seamless; the pair matched in essence and function.

The orientation was important, as was the relationship of the knives to each other, as was the light play, the reflectivity, and the mass of the form. I hand-carved and completed the Black Walnut and Redheart in a natural oil and wax finish, and created 304 stainless steel bezels to mount the associated doublet cabochons. This way, the location of each knife is clear, and the cabochons reflect the handle scales of the knives.

The forms of the Black Walnut came together beautifully, like an embrace, which is just what I wanted. They are rigidly mounted with stainless steel screws to the substantial base. It's made of Black Galaxy Granite from India, with coppery flakes in an inky, dark field. The base is heavy and thick, with neoprene feet for absolute stability and security. Into the granite base bottom, I carved a pocket to mount a sealed engraved black lacquered brass legend plate, so the details and materials will never be lost. It's visible in the photos below.

The sculpted form of the knife stand is a work of independent art. Everyone who sees it experiences a different view, a different idea, a hint of meaning and inspiration. Isn't this how it should be?

These are some of the very finest knives made; you won't see any like them anywhere, and I truly enjoyed creating this unique pair.

| Main | Purchase | Tactical | Specific Types | Technical | More |

| Home Page | Where's My Knife, Jay? | Current Tactical Knives for Sale | The Awe of the Blade | Knife Patterns | My Photography |

| Website Overview | Current Knives for Sale | Tactical, Combat Knife Portal | Museum Pieces | Knife Pattern Alphabetic List | Photographic Services |

| My Mission | Current Tactical Knives for Sale | All Tactical, Combat Knives | Investment, Collector's Knives | Copyright and Knives | Photographic Images |

| The Finest Knives and You | Current Chef's Knives for Sale | Counterterrorism Knives | Daggers | Knife Anatomy | |

| Featured Knives: Page One | Pre-Order Knives in Progress | Professional, Military Commemoratives | Swords | Custom Knives | |

| Featured Knives: Page Two | USAF Pararescue Knives | Folding Knives | Modern Knifemaking Technology | My Writing | |

| Featured Knives: Page Three | My Knife Prices | USAF Pararescue "PJ- Light" | Chef's Knives | Factory vs. Handmade Knives | First Novel |

| Featured Knives: Older/Early | How To Order | 27th Air Force Special Operations | Food Safety, Kitchen, Chef's Knives | Six Distinctions of Fine Knives | Second Novel |

| Email Jay Fisher | Purchase Finished Knives | Khukris: Combat, Survival, Art | Hunting Knives | Knife Styles | Knife Book |

| Contact, Locate Jay Fisher | Order Custom Knives | Serrations | Working Knives | Jay's Internet Stats | |

| FAQs | Knife Sales Policy | Grip Styles, Hand Sizing | Khukris | The 3000th Term | Videos |

| Current, Recent Works, Events | Bank Transfers | Concealed Carry and Knives | Skeletonized Knives | Best Knife Information and Learning About Knives | |

| Client's News and Info | Custom Knife Design Fee | Military Knife Care | Serrations | Cities of the Knife | Links |

| Who Is Jay Fisher? | Delivery Times | The Best Combat Locking Sheath | Knife Sheaths | Knife Maker's Marks | |

| Testimonials, Letters and Emails | My Shipping Method | Knife Stands and Cases | How to Care for Custom Knives | Site Table of Contents | |

| Top 22 Reasons to Buy | Business of Knifemaking | Tactical Knife Sheath Accessories | Handles, Bolsters, Guards | Knife Making Instruction | |

| My Knifemaking History | Professional Knife Consultant | Loops, Plates, Straps | Knife Handles: Gemstone | Larger Monitors and Knife Photos | |

| What I Do And Don't Do | Belt Loop Extenders-UBLX, EXBLX | Gemstone Alphabetic List | New Materials | ||

| CD ROM Archive | Independent Lamp Accessory-LIMA | Knife Handles: Woods | Knife Shop/Studio, Page 1 | ||

| Publications, Publicity | Universal Main Lamp Holder-HULA | Knife Handles: Horn, Bone, Ivory | Knife Shop/Studio, Page 2 | ||

| My Curriculum Vitae | Sternum Harness | Knife Handles: Manmade Materials | |||

| Funny Letters and Emails, Pg. 1 | Blades and Steels | Sharpeners, Lanyards | Knife Embellishment | ||

| Funny Letters and Emails, Pg. 2 | Blades | Bags, Cases, Duffles, Gear | |||

| Funny Letters and Emails, Pg. 3 | Knife Blade Testing | Modular Sheath Systems | |||

| Funny Letters and Emails, Pg. 4 | 440C: A Love/Hate Affair | PSD Principle Security Detail Sheaths | |||

| Funny Letters and Emails, Pg. 5 | ATS-34: Chrome/Moly Tough | ||||

| Funny Letters and Emails, Pg. 6 | D2: Wear Resistance King | ||||

| Funny Letters and Emails, Pg. 7 | O1: Oil Hardened Blued Beauty | ||||

| The Curious Case of the "Sandia" |

Elasticity, Stiffness, Stress, and Strain in Knife Blades |

||||

| The Sword, the Veil, the Legend |

Heat Treating and Cryogenic Processing of Knife Blade Steels |