"Concordia" Custom Master Chef's Knife

A stunningly beautiful custom master chef's knife in my "Concordia" design,

with beautiful and useful accessories makes this the king of the

kitchen!

Knife Details:

The Knife: "Concordia"

- Size: Length overall: 14.0" (35.6 cm), Blade Length: 9.0" (22.9 cm), Thickness: 0.145" (3.7 mm)

- Weight: 16.2 oz. (459 grams)

- Blade: 440C High Chromium Martensitic Stainless Steel, Hardened and Tempered, T3 Specialty Cryogenically treated to Rockwell C58, mirror polished

- Bolsters/Fittings: 304 High Nickel, High Chromium Austenitic Stainless Steel, mirror polished

- Handle: Sodalite Gemstone (Brazil)

- Type/Purpose/Origin: The Concordia is a popular

pattern I've made for many years, because it's simply a great chef's

knife design. The knife is a classic "Sabatier" style, originating

in France and well-recognized all over the world. The Concordia is

large, and I've made this one with the finest treatment and

presentation possible for a singular knife, and a beautiful, bold and

useful hardwood case and accessories.

Knife Blade Materials/Treatment

- Blade Steel Alloy: The knife blade of this

Concordia is 440C, hypereutectoid martensitic

stainless tool steel, my most

requested steel for good reason. When properly treated, 440C is a

dependable, reliable workhorse of extremely high corrosion

resistance, good toughness and high wear resistance. The

tremendously

high chromium in 440C along with the high carbon and moderate

molybdenum results in profuse chromium carbides, increasing

corrosion resistance as well as wear resistance. There is a reason

that 440C is the steel that all other stainless tool steels are

compared to. This steel is a high performer in the kitchen,

requiring little care other than a light wash. Air drying is fine;

it's absolutely corrosion resistant.

- Heat Treatment: The blade has my

T3 heat treatment, yielding astounding blade

performance and incredible

condition through advanced processing protocols. How advanced is

this treatment? It's a multi-stage cryogenic treatment,

involving temperatures ranging in over 1800°F

to -320°F (-196°C). The process is an evolution of my

advanced heat treating processes, and consists of 33 dedicated

and specific steps and takes 172 hours. This means that just to

heat treat this blade takes over a week. The reason for this is

scientific and critical, but yields the most stable, most

wear-resistant, most durable and long-lived structure of this

steel, profuse with fine multi-element carbides and a uniform

and unbelievably robust structure. This is a testament to my

determination to make the very best knives, steels, treatments

and kits in the modern world. I know of no one else who has

advanced the treatment to this level; it's unheard of in the

metals and knifemaking field. This is, simply

put, 440C at its very finest advanced condition.

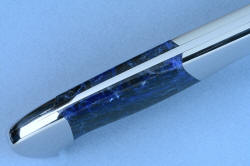

- Blade Finish: The blade and bolsters of this

knife are completely smooth and mirror polished. All the

hand-contact surfaces are rounded, contoured, and smooth, for a very

comfortable feel. The mirror polish not only makes the surfaces easy

to clean, it dramatically improves the corrosion resistance. I

mentioned before that this is the kind of blade and finish that I

use in my own kitchen, and cleaning is absolutely the easiest

possible, even with sticky foodstuffs like dates and dried fruits. A

simple brush with soapy water, a rinse, and air dry is all it takes

to clean these knives.

- Bolsters: I bolstered the knife with

my signature zero-care, high nickel, high chromium 304 austenitic

stainless steel bolsters, contoured and rounded for comfort of the

hand, and shaped and radiused in the front face for easy cleaning.

This is an extended length front bolster, and it allows a

comfortable "pinch" style grip of the spine when dicing, or fine

cutting when the knife user wants to "neck up" on the blade. The

bolsters are attached with multiple through-tang pins of 304 stainless

steel, and the mounting is permanent, as well as extremely

corrosion-resistant. This is the same steel used for stainless steel

nuts, bolts, and fasteners, and the bolsters are heavy, thick, and

solid, giving great balance to the knife. Did I mention that this

type of bolster is zero-care? Of course it is.

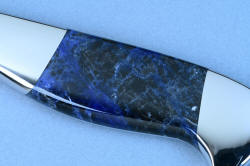

- Handles: The handle scales for the Concordia

are gemstone, chosen by my clients for a bold, blue color. Choosing

Brazilian Sodalite also added some fascinating pattern and light

play in the striking gemstone handle. Sodalite is a feldspathoid,

often used in jewelry, and this particular gemstone has a black

matrix for a bold, rich contrast. In the bright light, there is a

distinctive and striking shimmer that is difficult to show in any

photograph. The scales are bedded to the tang with a stress-free

mounting, locked under the bolster dovetails, rounded and smoothly

polished. The fit is flawless. The handle scales are solid and smooth, and simple to clean and

maintain, with just a soapy wash and rinse.

- Feel and Balance: The knife feels sizeable and

capable in the hand, with the balance point exactly at the heel of the blade. When

gripped with an overhand spine pinch at the extended front

bolster, this large knife feels light

and maneuverable, smooth and fresh, ready for any chef's task. A

simple rinse is all it usually takes to clean the bright, polished surface

in most functions, and the knife satisfies

food safety

requirements. While the spine is thick and strong, the

wide and deep hollow grind lightens the weight considerably.

The point is extremely thin and aggressive, yet tough and

well-supported by the blade geometry. This is a master

chef's knife made for accurate cutting, slicing, mincing,

and dicing, for generations. A true family heirloom.

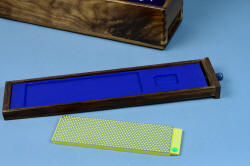

The Case, Prise, and Sharpener

Knife Case

- Size: Length: 17.9" (45.5 cm), Width: 5.5" (14 cm), Height: 4.75" (12.1 cm)

- Weight: 9 lbs., 3 oz. (4.2 kg)

- Materials: American Black Walnut Hardwood, Sodalite Gemstone, Laser Engraved Leatherette,

Neoprene feet, Engraved Black Lacquered Brass, 304 Stainless Steel Hinges and Fasteners

- Description: I wanted to make a very nice,

especially useful case for my client and for this exceptional knife. American

Black Walnut is a classic hardwood, beautiful and tough, and I made

this case in solid black walnut, with finger-jointed corners. I oiled the

hardwood with a Tung-oil and polymer stabilizing sealer, and after

drying completely, used a lacquer for a beautiful, rich and

easy-to-clean finish. The lid of the case has all stainless steel

hinges and screws for zero corrosion and care, and I included an

engraved black lacquered brass materials plate on the inside, coated

with acrylic. I also included a blue/silver/black polyester and

PVC "leatherette" laser-engraved hinge opening stop with my maker's mark, and

an extra one, too. The lid overhangs the sides for easy opening, and

the bottom has inset foam neoprene feet to protect any countertop

and reduce skidding. Notably is a Sodalite Gemstone drawer pull on

the right side.

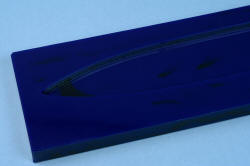

Knife Silicone Prise

- Inside: Knife Prise: My clients

requested a silicone prise for their knife, a particularly useful adjunct for the

knife. I make the prises myself, designing and making the molds and

using food contact-safe high strength silicone, hand-casting each one.

For this knife prise, I created a custom dye set that has deep royal

blues and wisps of black, working nicely with the black and blue of the

knife gemstone handle. Read more about this important accessory for

chef's knives on my

Chef's knives page at this link. The heavy prise sits on top of a

floating shelf inside the case. The knife prise can be removed from the

case by removing the bottom screw of the leatherette lid opening stop to

move it out of the way, pulling out the sharpener drawer, and pushing up

with the fingers on the shelf inside. The beautiful prise can be a

stand-alone knife holder, or can be used with the case, depending on my

client's preference. See the photos below.

- Knife Prise Size: Length: 16.5" (42 cm), Width: 4.5" (11.4 cm), Height: 1.0" (2.5 cm)

- Knife Prise Weight: 2 lbs., 7.7 oz. (1.1 kg)

- Knife Prise Material: Food grade-safe contact high density silicone rubber, hand-dyed,

hand-cast to fit this specific knife and case

Knife Sharpener Drawer and Prise

- Inside: Knife Sharpener: One of the important and critical needs

for the knife user, and the only maintenance he will perform himself

is knife sharpening. While my cryogenically treated knives have

incredible wear resistance, every knife will, sooner or later, need

sharpened. I detail this in great length on my

Kitchen, Chef's and

Culinary Page at this link. I decided to include a specialized

drawer for the sharpener, considering that the sharpener is

double-sided and needs a strong, non-slip, non-skid silicone prise

to use and to protect the counter, bench, table, or surface that the

knife is sharpened on. What better place to keep the sharpener and

prise than in the base of the case? I made a Black Walnut drawer,

and used the same gemstone as the knife (Blue Sodalite) and made a

polished drawer pull to add a very classy custom touch. The drawer can be

pulled completely out, the silicone prise removed, and the

double-sided sharpener fits perfectly in the pocket to provide a

non-slip holder while honing the blade.

- Sharpener Prise Size: Length: 14.8" (37.6 cm), Width: 3" (7.6 cm), Max Thickness: 0.5" (1.3 cm)

- Sharpener Prise Weight: 10.7 oz. (303 grams), with sharpener: 22.2 oz. (629 grams)

- Sharpener Prise Material: Food grade safe contact high density silicone rubber, hand-dyed,

hand-cast to fit this specific knife and case

- Sharpener (Hone): DMT double-sided diamond phenolic base, 325 mesh and 1200 mesh

- Drawer: American Black Walnut, Sodalite Gemstone, Stainless Steel drawer pull stud and fastener

My deepest thanks to my clients for their inspiration, guidance and

patience while I created this beautiful and useful project for their home.

May they use it in good health for the rest of their lives!

Thanks, M. and N. H.!

It’s amazing! We truly love it and it’s a beautiful piece of art! Thank you again so

much! Our kids are now campaigning to get it when we die!

Thanks again!!!!

Later: We are using and loving the knife—so sharp and precise!

--M. and N. H.