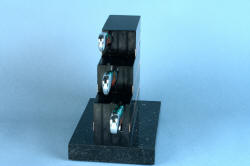

"Llano Sunrise" Custom Chef's Set

A great set of knives for everyday use in the fine kitchen, custom

made for a great client to match with their taste and decor in a

Texas-style kitchen. The name Llano comes from the Llano

Estacado, the staked plains of West Texas and the Panhandle extending

into Eastern New Mexico. The name Sunrise describes the visual

character of the gemstone handles, chosen by my clients for this custom

project.

Knife Details:

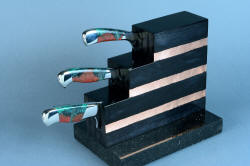

The Knives

This fine set consists of three knives to cover a wide range of

kitchen and chef's tasks. From the smallest to the largest knives:

Talitha, Eridanus, and Corvus:

"Talitha"

- Size: Length overall: 8.3" (21.1cm), Blade Length: 4.0" (10.2 cm), Thickness: 0.128" (3.3 mm)

- Weight: 6.1 oz. (173 grams)

- Blade: 440C High Chromium Martensitic Stainless Steel, Hardened and Tempered, T3 Specialty Cryogenically treated to Rockwell C58, mirror polished

- Bolsters/Fittings: 304 High Nickel, High Chromium Austenitic Stainless Steel, mirror polished

- Handle: Cuprite Mosaic Gemstone (Sonora,

Mexico)

- Type/Purpose/Origin: "Talitha" is a great small, tough knife, with a very stiff and strong

blade, an aggressive point and a compact design for working in tight

spaces and with smaller tasks. The blade has a light sweeping spine,

a trailing blade design (with the point trailing just higher than

the spine), and a wide, useful hollow grind at the termination

(where the grind meets the ricasso at the handle). The distinct

choil gives a definite location for the beginning of the cutting

edge, and the spine and tang is full and clean throughout, for easy

maintenance and comfortable grip. The handle shape has a good width

at the rear bolster, so the majority of mass rests in the palm of

the hand. A smooth, rounded inside handle curve means the fingers

can move and locate to a variety of grips, helpful with a smaller

knife. The knife feels tough and able, with a stiff blade, and a

handle that offers comfortable control.

Eridanus

- Size: Length overall: 10.5" (26.7cm), Blade Length: 6.0" (15.2 cm), Thickness: 0.136" (3.5 mm)

- Weight: 7.5 oz. (213 grams)

- Blade: 440C High Chromium Martensitic Stainless Steel, Hardened and Tempered, T3 Specialty Cryogenically treated to Rockwell C58, mirror polished

- Bolsters/Fittings: 304 High Nickel, High Chromium Austenitic Stainless Steel, mirror polished

- Handle: Cuprite Mosaic Gemstone (Sonora,

Mexico)

- Type/Purpose/Origin: "Eridanus" is a long,

narrow bladed knife, useful for filleting, boning, and delicate

carving. The narrow blade will reach into meats, vegetables, and

allow tight radius cutting. For instance, think of slicing the skin

off of melon parts, filleting fish, or small cuts of meat. The blade

has a curved cutting edge at the point, giving it moderately high

strength, and the long straight cutting edge gives it the

performance of a slicing knife. The full tang knife has a very

smooth and even spine and tang, for comfort and easy cleaning, and

the handle has a good forward quillon to protect the hand from

sliding forward. The substantial belly of the handle means the knife

is comfortable and secure, the rear bolster balances the knife so

the blade feels light and maneuverable.

Corvus

- Size: Length overall: 11.5" (29.2cm), Blade Length: 7.5" (19.1 cm), Thickness: 0.133" (3.4 mm)

- Weight: 10.1 oz. (286 grams)

- Blade: 440C High Chromium Martensitic Stainless Steel, Hardened and Tempered, T3 Specialty Cryogenically treated to Rockwell C58, mirror polished

- Bolsters/Fittings: 304 High Nickel, High Chromium Austenitic Stainless Steel, mirror polished

- Handle: Cuprite Mosaic Gemstone (Sonora,

Mexico)

- Type/Purpose/Origin: "Corvus" is a design based

on a more traditional Sabatier, or French Chef's knife, but with

some distinctive differences. The blade shape has the useful curve

of this type of knife, made specifically for cutting board use,

rocking on the board, dicing, chopping, and slicing. The blade is

long and large, but incredibly thin, because it's hollow ground. The

deep hollow grind will give the life literally generations of use,

especially since the knife should only need to be sharpened about

once a year. How do I know this? This is the exact knife design that

I use in my own kitchen. The substantial blade is beautifully mirror

finished for super-easy cleaning, and the point is thin and stiff.

The handle is compact, making the knife easy to grip with the

fingertips for accurate dicing and chopping, while not being too

large and heavy. The large heel allows the blade to make certain

contact with the board, and the fingers are nestled away in the

slight front and rear quillons while the belly in the handle gives a

comfortable grip. I love my Corvus in the kitchen, and my client

will too.

Knife Blade Materials/Treatment

- Blade Steel Alloy: All three blades in this set

are hypereutectoid martensitic

stainless tool steels, 440C, my most

requested steel for good reason. When properly treated, 440C is a

dependable, reliable workhorse of extremely high corrosion

resistance, good toughness and high wear resistance. The extremely

high chromium of 440C along with the high carbon and moderate

molybdenum results in profuse chromium carbides, increasing

corrosion resistance as well as wear resistance. There is a reason

that 440C is the steel that all other stainless tool steels are

compared to. This steel is a high performer in the kitchen,

requiring little care other than a light wash. Air drying is fine;

it's absolutely corrosion resistant.

- Heat Treatment: The blades have my

T3 heat treatment, yielding astounding blade

performance and incredible

condition through advanced processing protocols. How advanced is

this treatment? It's a multi-stage cryogenic treatment,

involving temperatures ranging in over 1800°F

to -320°F (-196°C). The process is an evolution of my

advanced heat treating processes, and consists of 33 dedicated

and specific steps and takes 172 hours. This means that just to

heat treat this blade takes over a week. The reason for this is

scientific and critical, but yields the most stable, most

wear-resistant, most durable and long-lived structure of this

steel, profuse with fine multi-element carbides and a uniform

and unbelievably robust structure. This is a testament to my

determination to make the very best knives, steels, treatments

and kits in the modern world. I know of no one else who has

advanced the treatment to this level; it's unheard of in the

metals and knifemaking field. This is, simply

put, 440C at its very finest advanced condition.

- Blade Finish: The blades and bolsters of these

knives are completely smooth and mirror polished. All the

hand-contact surfaces are rounded, contoured, and smooth, for a very

comfortable feel. The mirror polish not only makes the surfaces easy

to clean, it dramatically improves the corrosion resistance. I

mentioned before that this is the kind of blade and finish that I

use in my own kitchen, and cleaning is absolutely the easiest

possible, even with sticky foodstuffs like dates and dried fruits. A

simple brush with soapy water, a rinse, and air dry is all it takes

to clean these knives.

- Bolsters: I bolstered the three chef's knives with

my signature zero-care, high nickel, high chromium 304 austenitic

stainless steel bolsters, contoured and rounded for comfort of the

hands, and shaped and radiused in the front face for easy cleaning.

They are attached with multiple through-tang pins of 304 stainless

steel, and the mounting is permanent, as well as extremely

corrosion-resistant. This is the same steel used for stainless steel

nuts, bolts, and fasteners, and the bolsters are heavy, thick, and

solid, giving great balance to the knife. Did I mention that this

type of bolster is zero-care? Of course it is.

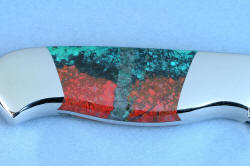

- Handles: The handle scales for the set were

custom, chosen by my clients to fit their home decor. This is

cuprite mosaic, a mosaic of two types of associated minerals. The

bright red cuprite is a secondary mineral of copper oxide, and the

large compacted forms are cemented naturally into a sold mass. That

mass is bonded with chrysocolla, a hydrated copper silicate. In

fact, the copper silicate when oxidized forms the copper oxide, so

the stone demonstrates a transition of transformation in mineral

type and composition. The black mineral at the boundaries of the two

is tenorite, formed by the weathering of the oxidized copper sulfate

ore bodies, and associated with cuprite, malachite, azurite, goethite

and hematite. This material comes from the state of Sonora, Mexico,

directly south of Arizona

(and is typically called "Sonoran Sunrise"). The cuprite mosaic has a

slight textured finish, is solid and smooth, and simple to clean and

maintain, with just a soapy wash and rinse.

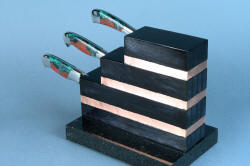

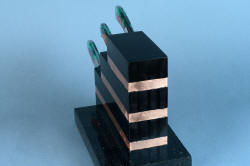

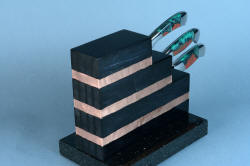

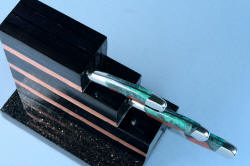

The Stand/Block

My clients desired a certain look to match their decor of

southwestern, native, and natural dark finish. The use of copper, and

black simple forms throughout their decor was the design idea for the

block for the knives.

- Size: Length: 9.0" (22.9 cm), Width: 5.8" (14.7 cm), Height: 8.5" (21.6 cm)

- Weight: 10.00 lbs. (4.5 kg)

- Materials: Hard (Rock) Maple Hardwood, Poplar Hardwood, Copper sheet strip, Black Galaxy Granite (India), Neoprene feet, Engraved Black Lacquered Brass, 304 Stainless Steel Fasteners

- Description: Designing by custom for my client,

I developed a simple motif, incorporating Native American

"stair-step" design arrangement. This is a very ancient geometric

arrangement, found on early Native pottery and hand-decorated items.

I built the solid, incredibly stout mass of the block in hard maple

(also called rock maple for a reason!). This is a very

hard, durable, and strong massive wood. The spacers for the slips

(the location of the blades) were built in poplar. Poplar is a

moderately soft wood, so it's great for the blades to have contact

with, particularly at the cutting edges. This beds the knife blades

safely and with no wear to the edges. My client requested all black,

or minimized tone appearance, so I ebonized the maple with

successive immersions in dye, penetrating the fibers of the wood,

between fine sanding steps. I textured the copper strips, antiqued

them, and accurately inlaid them in the hardwood block, following

the pattern of threes of the steps and knives. The block is coated

with a hard, glossy topcoat, for easy cleaning with a damp wipe. To

add mass to the piece and prevent movement and toppling over, I cut,

finished, and mounted a Black Galaxy Granite base to the block with

stainless steel screws. This is a beautiful granite from India, and

it has some translucency with copper flakes naturally throughout. I

mounted neoprene feet which lift the block off the counter to allow

drying and prevent abrading any surface of countertop. I milled an

inlay pocket in the base, and made and mounted an engraved black

lacquered brass legend plate, detailing the materials used in the

piece. The weight and mass of the stand and block, at 10 lbs.,

assures that it's stable and won't move in use.

This was a great project, and I'm proud to display it here, as proud as

my client will be to have it in their fine kitchen for many years to come!

Thanks, L. and D. S.!