"Horus" Custom Tactical Combat Knife

"Horus" Custom Tactical Combat Knife

- Size: Length Overall: 13.75" (34.9 cm), Blade Length:

8.2" (20.8

cm), Thickness: .244" (6.2 cm)

- Weight: Knife: 1 lb., 5.0 oz., Sheath (with all

accessories): 1 lb., 13 oz.

- Blade: Bead blasted ATS-34 high molybdenum

martensitic stainless tool steel, hardened and tempered to

HRC58

- Bolsters/Fittings: Bead-blasted 304 austenitic high

nickel, high chromium stainless steel

- Handle: Black canvas reinforced Micarta

phenolic

- Sheath: Kydex, Aluminum, Nickel Plated Steel, all Stainless

Steel Locking Components

- Accessories: Polypropylene and Nylon belt loop

extender with Firesteel/Magnesium fire starter, Fine DMT diamond

abrasive pad sharpener, Maglite XL200®

flashlight in HULA assembly, all stainless steel fittings

and corrosion resistant high strength aluminum alloy.

- Commemorative: Machine-engraved black lacquered

brass flashplate, and machine-engraved stainless steel bolsters.

- Knife: Custom made for a Navy SEAL Team member,

this is as serious as a knife gets. The knife pattern is my Horus

design, named for a very ancient mythological god of war and

hunting, which is exactly what our Navy SEAL Team members do. The

blade is deeply and beautifully ground ATS-34 high molybdenum

stainless tool steel, a high "chrome-moly" tool steel with a proven

record of high wear resistance coupled with high toughness

(resistance to deformation and breakage), as well as high heat

resistance. ATS-34 for the steel choice allows a very thin blade

grind profile, producing an extremely tough and sharp cutting

edge with high wear resistance. This steel will not change temper

unless exposed to over 1000 degrees Fahrenheit, so this is a very

heat-resistant blade indeed. The point also benefits from this steel

choice, as it can be maintained very thin and sharp, allowing very

low angles for piercing and point penetration, without sacrificing

toughness. The aggressive point has a two-thirds blade length top

swage for the correct geometry to apply extreme peircing pressure at the

point without sacrificing blade strength. I hollow ground the blade

deeply and with perfect symmetry, and the large belly of the blade

provides plenty of sweeping, razor-keen double-bevel cutting edge.

The knife has 2.5" of my tough "hammerhead" rip tooth serrations in

the recurve area for smooth and reliable cutting of a variety of

materials without snagging. I've left enough spine in the blade to

fully support the powerful blade, and no filework leaves the spine

clean and smooth without the possibility to trap and hold debris.

The curvature of the knife is a piece of sculptural art, but art is

not all that lives in the graceful lines. The curves all have

purpose too, from the thumb rise to aid in knife grip and engage the

sheath locking mechanism to the large handle quillons that

positively lock the handle into the hand comfortably with a good

belly and nice heel drop for the hand. The knife is bolstered with

zero-care high nickel, high chromium 304 stainless steel alloy

bolsters, permanently attached with zero clearance peened pins. This

is the same steel used to make stainless steel nuts, bolts and

fasteners and is extremely tough and highly corrosion resistant.

They are bead-blasted and the front bolsters hold custom high

resolution, deep machine-engravings of the frog skeleton that is a

special accent characteristic of the Navy's finest warriors. The

rear bolster has a substantial 5/16" chamfered lanyard hole, and the

dovetailed bolsters bed a pair of tough, waterproof, and durable

canvas reinforced Micarta phenolic handle scales secured with ten

304 stainless steel through-tang pins. The knife feels comfortable

and highly effective in both forward and reverse grip, with the

balance point at the point of the front bolster, and the center of

percussion at the belly of the blade.

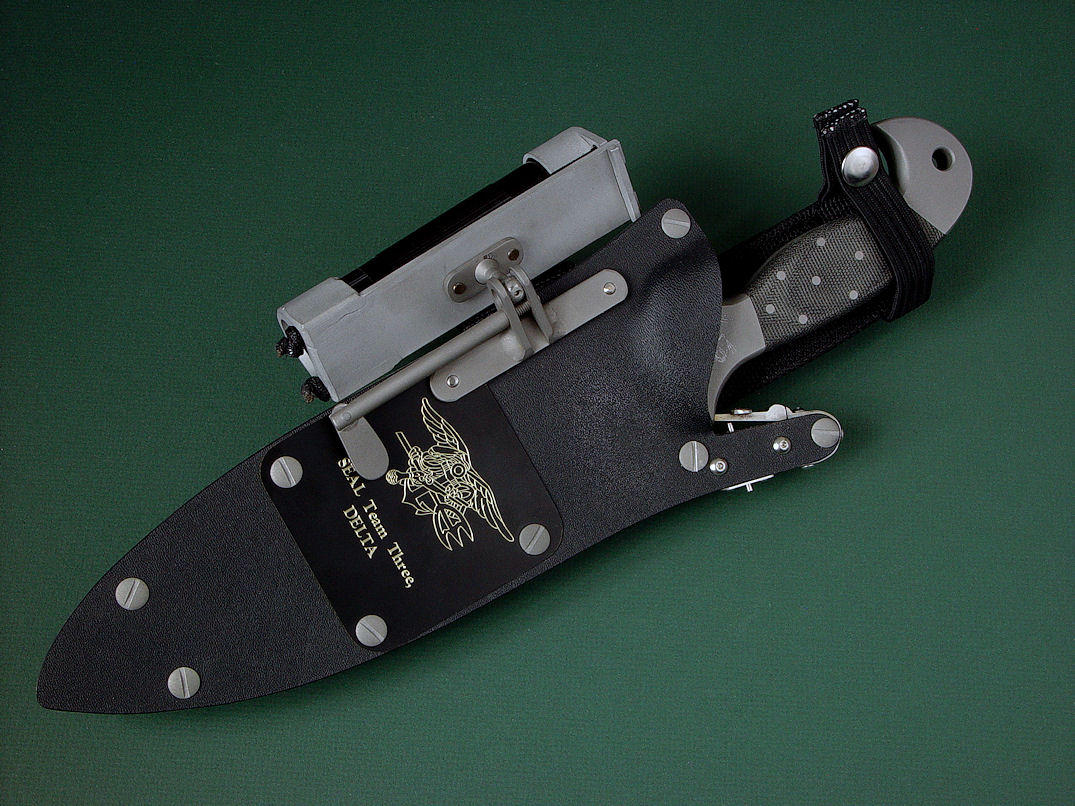

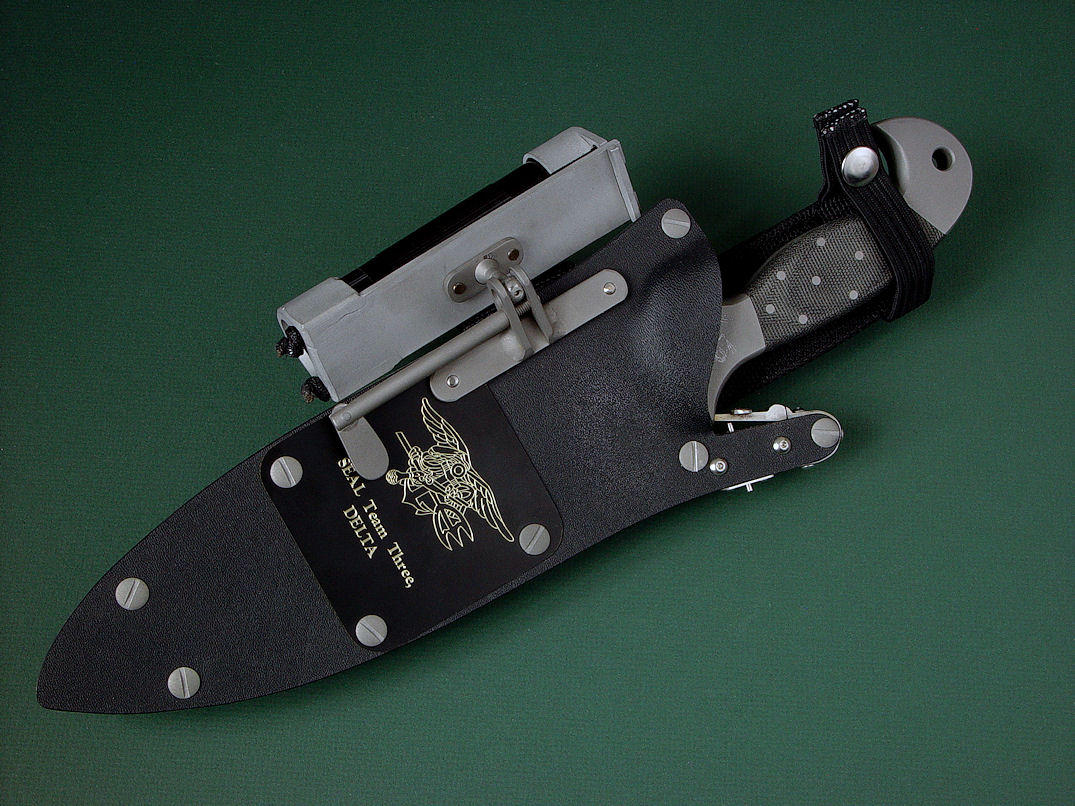

- Sheath: The sheath for this beauty had is one of my

positively locking models, and is built of double thickness

kydex over a 5052H32 high strength corrosion-resistant aluminum welt

frame. The locking components are all stainless steel,

including the spring, tang and hardware for longevity and

corrosion resistance. The sheath is secured with all bead

blasted double slotted stainless steel Chicago screws, and has two

sets of reversible

corrosion-resistant aluminum 1.75" belt loops. The

die-formed high strength, corrosion resistant aluminum loops can be

positioned in three different positions along the welt-frame, and on

either side of the sheath for the widest variety of wear options. The action of

the sheath is smooth and clean, locking solidly.

- Horizontal Belt Loop Plate: Since, with the

locking sheath, the sheath can be worn in any position, even upside

down, I included a horizontal belt loop plate. This accommodates

wear horizontally and can be bolted to either side of the sheath for

a reversible option. It is made of die-formed and riveted 5052H32

high strength corrosion resistant aluminum alloy, bead blasted for

glare reduction.

- Belt Loop Extender: I included one of my

Ultimate belt loop extenders, which can be used to lower the knife

to a more traditional position if the knife is worn on the belt. The

polypropylene accessory is waterproof, durable, and extremely stout.

The extension is mounted with 304 stainless steel straps and

stainless steel machine screws attached to the existing stainless

steel Chicago screws, and the assembly is stiffened by multiple

zigzag nylon stitching to prevent the extension from folding,

bending, or collapsing when the knife is extracted from the sheath.

The belt loop accommodates up to a 2.5 inch wide belt, and has a

top placement shock cord with stainless steel snap retention to

prevent the knife handle from flopping around during active

movements. At the lower back of the extension I've included

a custom fit pocket for a DMT (Diamond Machining Technology)

Mini-Sharp diamond-nickel abrasive hone, to bring up the cutting

edge in the field with ease, even on this high-alloy wear-resistant

blade. The pocket for this tool is situated at the

sheath back and against the body, so the sharpener can not be

removed unless the sheath is off the body. I also added a specially modified

critical survival component to this accessory: the

Firesteel/Magnesium block with custom fittings. These blocks are

waterproof and durable, with soft magnesium that can be easily

shaved off with the knife blade, and a Firesteel striker to ignite

the magnesium shavings when placed into tinder to start a fire. A

unique addition to this block is the stainless steel rod guard. This

minimizes the possibility of the Firesteel contacting any other

metals and causing accidental sparks and ignition when worn or

removed, guards the knife tip (or swage) when the blade is dragged

over the Firesteel, helps concentrate and guide the spark direction,

and offers a variety of mounting options on any gear or pouch,

besides on the sheath extender's industrial strength Velcro straps.

Being made of all 304 stainless steel hardware, fittings and

fasteners, it will not corrode or rust.

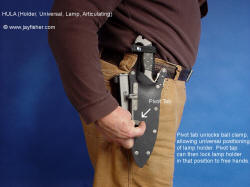

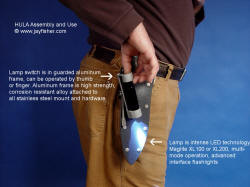

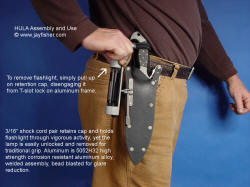

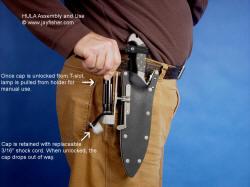

- HULA and Maglite XL200: Included in this

professional assembly is my latest offering for field use, the HULA.

The Holder, Universal, Lamp, Articulating (HULA), is my answer to a

call for not just a backup lamp that I've provided on previous

Ultimate Extender packages, but an actual main or key professional

grade lamp and mount assembly. The lamp I included is the Maglite

XL200, perhaps the most sophisticated programmable flashlight made

today, with five modes of operation and infinite power settings. The

lamp is a powerhouse of options and longevity, with ultra bright LED

technology that is dependable and tough. The only thing the lamp

needed was a reliable, adjustable, dependable and corrosion proof

way to carry it on the sheath, so I designed the HULA. This special

holder will hold any flashlight that is 1" by 4.75" and also

accommodates the Maglite XL100 flashlight that has different

options. The holder lamp frame is made of welded 5052H32 high

strength corrosion-resistant aluminum alloy, for the highest

durability and corrosion resistance combined with low weight. The

lamp is held in custom made socket with a retaining cap that is

maintained in a T-slot lock by the elastic tension of replaceable

shock cord straps. The T-slot lock can be negotiated even in the

dark due to it's simple and clever design and construction. The lamp

can be turned on and off within the holder, and can even have

selected modes while still in the control of the holder. One of the

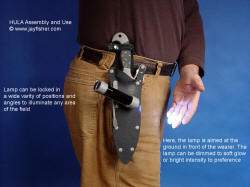

best features of this assembly is a ball joint and pinch mechanism.

This is a very old mechanism, dating back to 200BC, where a ball

sits in a dedicated socket, and is held there by the tension of a

screw. The ball joint frame, ball, tangs, screw and mounting

hardware are all welded 304 high nickel, high chromium stainless

steel which is bead blasted for glare reduction. This is a very

tough assembly that will probably outlast the knife owner. What it

offers is an articulating adjustment, aiming and positioning of the

lamp, while still mounted on the knife sheath, wherever the knife

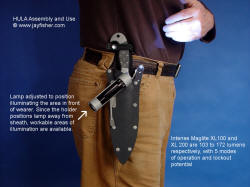

sheath is mounted on the body. In the traditional belt line position

(shown in the photos below), the lamp can be aimed at the ground in

front of the wearer (great for movement), or aimed at any object or

person in front of the wearer, while freeing the hands for a weapon,

tool, or carry. I'm certain that this new development will be highly

popular with search and rescue and disaster response teams. Since

the lamp can be dimmed infinitely, the setting can allow soft light

for subdued movement, and various settings on the lamp can aid in

emergencies to signal and draw attention, depending on the program

selected. The lamp can even be program-locked to prevent unwanted

turning on, even if the switch is operated. If the wearer needs the light in his hand, he simply pulls

up on the T-slot locking cap, pulls the lamp from the socket, and

replaces the cap so it won't bounce around. I've done my research,

and created simply the finest flashlight accessory made in the world

today, custom made to mount to my locking sheaths, the best locking

sheaths made in the world today. One more important point: the bolt

pattern and arrangement allows the HULA to be bolted to twelve

positions along the welts of the sheath. Talk about flexibility! There are

much more to these accessories; learn about these critical

accessories on a special page on my site at this link. Mounting,

care, and use instructions are posted there.

- Additional Engraved Flash plates: I've included

an increased density graphic black brass flashplate and red brass

box or stand commemorative flashplate to honor our SEAL Team member

after his service and the retirement of the knife. That way, he'll

have several and can keep one pristine for his mantle.

- I am humbly honored that one of our finest will be carrying this

knife into the most serious business that there is. God bless our

military members and our allies who protect our freedoms and lives of all

those we love.

Thanks, G. T.!

Jay,

Hello; first, I love the knife. I got home from pre-deployment leave on the 25th and the knife was

the first thing I opened. It was amazing, just like I wanted it to be. Then I packed up and left

for Afghanistan on the 27th. I have used it for many jobs and I love the way it feels and cuts. I just

hope I can keep it as sharp as when I got it. After that day long ago when I left your shop, I set to

learning how to sharpen knives, so that when I needed to sharpen one of the knives you made, I would do

so without messing it up. I now have many types of stones and spent many hour on YouTube, read the book

Razor Edge Sharpening, and spent many hours with old knives, so now I think I have it down.

The kit (accessories) that you sent has been great. I have carried

the knife two different ways: either with the kit inside the E & E bag

that goes on all my ops, or without the kit and on my person.

Take care,

--G.

Please click on thumbnail knife photos